So, can you ferment wine in stainless steel? The answer is a definitive yes. It stands as the superior method for modern winemaking, whether you are a commercial producer or a dedicated home winemaker. The primary advantages of stainless steel fermentation unlock your grapes’ true potential.

You gain unparalleled flavor purity, precise temperature control, and flawless hygiene.

This year, choose to ferment wine in stainless steel to elevate your craft and achieve professional-quality results with every batch. 🍷

PRESERVING TRUE FRUIT FLAVOR

When you choose to ferment wine in stainless steel, you are making a clear choice for purity. The primary goal is to let the grape’s natural character take center stage. Stainless steel helps you achieve this by creating a perfectly neutral environment for fermentation.

HOW STEEL’S NEUTRALITY PROTECTS GRAPE AROMA

Stainless steel tanks are chemically inert. This means they do not add any flavors or aromas to your wine. Think of the tank as a blank canvas. It allows the grape’s raw splendor and unique varietal notes to express themselves fully. You get to taste the fruit, not the container.

This is very different from using wood barrels. New oak barrels impart distinct flavors like vanilla, coconut, or spice. While these flavors can soften a high-tannin wine like Cabernet Sauvignon, they can easily overpower the delicate profile of a fruity Sauvignon Blanc.

The key difference is control. With steel, you capture the pure essence of the grape. You can always add oak character later if you choose, but you can never remove it once it’s there.

Here is a simple breakdown:

- Stainless Steel Tanks: Flavorless and odorless, they are perfect for showcasing the fruit’s true character.

- Wood Barrels: They strongly affect the flavor of the wine, which is ideal for certain styles but not for preserving pure fruit notes.

AVOIDING FLAVOR CONTAMINATION

Flavor purity is not just about what you don’t add; it’s also about what you prevent. The non-porous surface of stainless steel is your greatest ally in hygiene. Wooden barrels have tiny pores and grains where spoilage microbes can hide, making them difficult to clean completely. These microbes can introduce unwanted, off-flavors into your wine.

Stainless steel’s smooth surface eliminates these hiding spots. It is easy to clean and sanitize, ensuring that each batch starts in a pristine environment. This excellent hygiene prevents microbial contamination. It also protects your wine from chemical taints like TCA, also known as “cork taint.” Because steel is non-porous, it cannot harbor or spread the compounds that cause this musty, unpleasant aroma. Your wine remains clean, fresh, and true to the grape.

ACHIEVING UNMATCHED TEMPERATURE CONTROL

Temperature is one of the most critical factors in winemaking. It directly influences yeast health, flavor development, and the final quality of your wine. When you ferment wine in stainless steel, you gain an incredible advantage: the ability to manage temperature with surgical precision.

THE ROLE OF COOLING JACKETS

Different wines need different temperatures to thrive. Your goal is to keep the yeast happy and active within its ideal range.

| Wine Type | Optimal Temperature Range |

|---|---|

| Most Red Wines | 70°F to 85°F (21°C to 29°C) |

| White Wines | 45°F to 60°F (7°C to 16°C) |

For example, you might ferment a crisp Chardonnay in a steel tank at a very cool temperature to preserve its delicate fruit aromas. For a red wine, some winemakers even push temperatures up to 90°F (32°C) for short periods to extract more color and flavor from the grape skins. Cooling jackets make these precise adjustments possible.

PREVENTING STUCK FERMENTATIONS

A “stuck fermentation” happens when yeast stops converting sugar to alcohol before the job is done. One of the main causes is excessive heat. If the temperature gets too high, the yeast becomes stressed and can die off.

This is where precise temperature control becomes your safety net. By using a cooling jacket to keep the fermentation from overheating, you prevent yeast stress. Healthy, happy yeast works consistently, ensuring a complete and successful fermentation. This modern equipment is a key investment for creating a stable environment, leading to better, more reliable wine every time.

THE GOLD STANDARD IN HYGIENE

You work hard to grow or select the perfect grapes. The last thing you want is for spoilage to ruin your efforts. Hygiene is not just important in winemaking; it is everything. Stainless steel tanks are the undisputed champion of cleanliness, providing a secure environment for your wine.

WHY EASY CLEANING MEANS BETTER WINE

Stainless steel has a smooth, non-porous surface. It has no tiny cracks, pores, or grains for microbes to hide in. This physical property makes cleaning incredibly simple and effective. Unlike other materials, steel does not absorb flavors or contaminants from previous batches.

- Wood Barrels: Are porous and can harbor deep-set microbes that are nearly impossible to remove.

- Plastic Fermenters: Can scratch easily, creating new hiding spots for bacteria over time.

- Stainless Steel: Remains smooth and easy to sanitize, batch after batch.

A simple cleaning and sanitizing routine restores the tank to a perfectly neutral state. A clean tank means your wine tastes exactly as you intended, without any lingering off-flavors from past fermentations. This consistency is the hallmark of a professional process.

ELIMINATING SPOILAGE RISKS

Spoilage microbes, like unwanted yeast and bacteria, are the enemy of good wine. They can produce unpleasant aromas, from barnyard smells to vinegar notes, that completely mask the fruit. These microbes thrive in environments that are difficult to clean.

Scientific studies show that spoilage microbes can form biofilms, or sticky layers of cells, on many surfaces, including both wood and stainless steel. The critical difference is that you can completely remove these biofilms from steel with standard cleaning and sanitizing agents. On a porous surface like wood, these microbes can embed themselves deep within the material, surviving to contaminate your next batch.

Note: Proper cleaning eliminates the risk of spoilage organisms like Brettanomyces and acetic acid bacteria. This ensures your wine remains fresh, clean, and stable.

When you ferment wine in stainless steel, you gain the power to eliminate these threats before they ever become a problem. This control gives you peace of mind and protects the quality of your final product.

CHOOSING THE RIGHT STAINLESS STEEL TANK

Selecting the right tank is a critical decision that impacts your entire winemaking process. Your choice influences fermentation dynamics, operational efficiency, and the final quality of your wine. You need to consider factors like size, shape, steel grade, and volume type to build the perfect stainless steel tank setup for your goals.

KEY FACTORS: SIZE AND SHAPE

The dimensions of your tank are not just about fitting it into your space; they directly affect how your wine ferments. The shape of the tank changes the pressure on the yeast and the way CO2 escapes, which can alter the final flavor profile.

- Tall, Narrow Tanks: These tanks create more pressure on the yeast at the bottom. This often leads to a faster, more turbulent fermentation. The rapid release of CO2 can scrub some volatile aromatics from the wine, making this shape better for certain robust styles.

- Wide, Short Tanks: These tanks put less pressure on the yeast. Fermentation tends to be slower and gentler. This helps preserve delicate fruit and floral aromas, making this shape ideal for aromatic white wines. It is also easier to keep certain yeast strains suspended in a wider tank.

Pro Tip: If you have specific production goals or space constraints, you don’t have to settle for a standard size. Specialized manufacturers like Chenma offer custom tank engineering, allowing them to design and build a tank perfectly adapted to your unique situation.

304 VS. 316 STEEL: WHICH IS BEST?

When you look at stainless steel tanks, you will see two common grades: 304 and 316. While both are excellent for winemaking, there is a key difference.

- 304 Stainless Steel: This is the industry standard. It offers great corrosion resistance and is suitable for most winemaking applications. It is durable, easy to clean, and provides a perfectly neutral environment.

- 316 Stainless Steel: This is a premium-grade steel. It contains an element called molybdenum, which gives it superior resistance to corrosion, especially from chlorides and acids.

You should choose 316 steel if you plan to use aggressive, chloride-based sanitizers or if you work with very high-acid wines. The enhanced protection ensures your tank will last for decades without any risk of pitting or corrosion. It is an investment in maximum durability and peace of mind.

VARIABLE CAPACITY VS. FIXED VOLUME

Your next choice is between a fixed volume tank and a variable capacity (or variable volume) tank.

A fixed volume tank is exactly what it sounds like—it holds one specific volume. It is perfect when you consistently produce the same batch size.

A variable capacity tank, however, offers incredible flexibility. These tanks feature a floating lid that you can lower onto the surface of the wine. An inflatable gasket then creates a perfect airtight seal. This design offers several key advantages:

- Prevents Oxidation: You can adjust the tank’s volume to match any batch size, eliminating the empty headspace where oxygen would cause spoilage. This is perfect for small batches or for racking off sediment without moving the wine to a smaller container.

- Increases Versatility: You can use a single tank for fermentation, aging, and bottling. It allows you to produce different wine styles—red, white, or rosé—and experiment with new blends without needing multiple tank sizes.

- Supports Growth: As your production grows, the same tank can handle larger volumes. You can start with small batches and fill the tank to higher levels in future harvests, saving you from buying new equipment.

When choosing a supplier, look for one that provides comprehensive support. Reputable companies offer turnkey project services, guiding you from initial process design and equipment manufacturing all the way to installation and technical training. To ensure safety and durability, always check for quality certifications like ISO 9001 (for quality management), ISO 14001 (for environmental standards), and CE certification (for European safety compliance).

ESSENTIAL COMPONENTS FOR A MODERN SETUP

A great tank is only the beginning. Your complete stainless steel tank setup needs the right components to function effectively. These essential parts give you control, visibility, and security throughout the fermentation process. Equipping your tank correctly turns it into a powerful winemaking tool.

MUST-HAVE VALVES AND FITTINGS

Valves and fittings are the control points of your setup. They allow you to move wine, manage pressure, and monitor the process safely and hygienically. You will want to include several key components.

- Racking Arm: This is a tube inside the tank that you can rotate. It lets you drain clear wine from above the sediment, ensuring a cleaner transfer.

- Sight Glass: A small window on the tank or in a valve lets you see the wine’s clarity and level without opening the lid.

- Pressure Relief Valve: This is a critical safety feature. It automatically releases excess pressure during fermentation, preventing any risk of tank damage.

- Sample Valve: A small tap allows you to take samples for tasting or testing without contaminating the main batch.

- Butterfly or Ball Valves: These are used at the bottom of the tank for draining and transferring the wine.

INTEGRATING TEMPERATURE PROBES

You learned how cooling jackets control temperature. A temperature probe is the brain behind that operation. This probe, inserted into a thermowell on the tank, constantly measures the wine’s temperature. It sends this information to a controller, which then turns the cooling system on or off as needed. This automation maintains the exact temperature you set, ensuring a perfect fermentation without constant manual checks.

CHOOSING THE RIGHT AIRLOCK

An airlock is a simple but vital device. It creates a one-way gate on top of your tank.

The airlock allows the carbon dioxide (CO2) produced during fermentation to escape. At the same time, it blocks oxygen and airborne microbes from getting in and spoiling your wine.

There are several styles, but all perform this essential function. A properly fitted airlock protects your wine from oxidation and contamination, preserving its fresh flavors and aromas from start to finish.

THE FERMENTATION PROCESS STEP-BY-STEP

You have your tank and all the right components. Now it is time for the most exciting part: making the wine. Following a clear, step-by-step process ensures you get consistent, high-quality results. This guide walks you through the essential stages, from preparing your tank to protecting your finished wine.

DEEP CLEANING AND SANITIZING

A successful fermentation begins with a perfectly clean environment. Your stainless steel tank’s non-porous surface makes this step straightforward and effective. You must remove any physical debris before you sanitize.

First, you perform a deep clean. This removes tartrates, pigments, and other residues from previous use. You can use several industry-standard agents for this job.

- Caustic Cleaners: These strong alkaline solutions, like caustic soda (NaOH) or soda ash, are excellent for dissolving organic soils and tough stains left after fermentation.

- Citric Acid: You often use this mild acid after a caustic wash. It neutralizes any alkaline residue and helps dissolve mineral deposits, leaving the steel surface pristine.

- Hot Water: Never underestimate the power of a thorough hot water rinse. It is a great agent for both cleaning and sanitizing.

After cleaning, you sanitize. Sanitizing eliminates invisible microbes that could spoil your wine. Peroxyacetic acid (PAA) is a superior choice for this. It works well at cool temperatures, destroys harmful bacteria, and breaks down into harmless substances, so it is safe for your wine and the environment.

Remember: A clean tank is a neutral tank. This step guarantees that the only flavors in your wine come from your grapes, not from leftover microbes.

KEY STEPS TO FERMENT WINE IN STAINLESS STEEL

With a clean and sanitized tank, you are ready to begin. The question “can you ferment wine in stainless steel?” is answered with these simple, controlled actions. This process gives you complete command over the final product, a key advantage for any serious home winemaker.

- Fill the Tank: Transfer your grape must (the unfermented juice) into the tank.

- Add Yeast: Pitch your chosen yeast strain into the must to kick off fermentation.

- Monitor Daily: This is the most critical phase. You must track the fermentation’s progress every day to ensure the yeast is healthy and happy. You should measure two key things:

- Brix: This measures the sugar content. You will see the Brix level drop by about 1-3 degrees each day as the yeast converts sugar into alcohol. A drop that is too fast can mean the fermentation is too hot.

- Temperature: Yeast creates heat as it works. You must use your cooling jacket to keep the temperature in the ideal range. For most reds, this is 70-85°F (21-29°C). A stable temperature prevents yeast stress and avoids a stuck fermentation.

Tracking these numbers daily helps you spot problems early. It allows you to make small adjustments to maintain a perfect environment. When you ferment wine in stainless steel, this level of control is your greatest asset.

PROTECTING THE HEADSPACE POST-FERMENTATION

Once the Brix level drops to zero, fermentation is complete. Your yeast has consumed all the sugar. Now, your primary goal is to protect the wine from its biggest enemy: oxygen. The empty space between the wine’s surface and the tank’s lid is called headspace. Oxygen in the headspace will damage your wine’s delicate aromas and flavors.

You can protect your wine by displacing the oxygen with a blanket of inert gas. Argon is the best choice for this job. While some use nitrogen, it is only slightly lighter than air and tends to mix instead of forming a protective layer.

Using inert gas correctly is crucial. Follow these steps to create a safe and effective gas blanket.

- Set Low Pressure: Start with your regulator at zero. Open it very slowly to a low pressure, around 1-5 PSI. You want the gas to flow gently, like a warm breath.

- Use Wide Tubing: A larger hose allows the gas to exit slowly and without turbulence. A high-velocity jet of gas will mix with the air instead of displacing it.

- Aim Parallel to the Surface: Do not point the hose directly down at the wine. Direct the flow horizontally across the surface. This allows the heavier argon to settle gently and form a perfect blanket.

Following this procedure answers the final question of “can you ferment wine in stainless steel?” with a resounding yes, from start to finish. When you ferment wine in stainless steel and protect it properly, you lock in the freshness and quality you worked so hard to create.

CAN YOU FERMENT WINE IN STAINLESS STEEL?

Yes, you can ferment wine in stainless steel, and the techniques vary based on the wine you want to create. Your stainless steel tank gives you the control to master both red and white wine styles. You just need to adapt your approach for each one.

TECHNIQUES FOR RED WINE FERMENTATION

When you ferment red wine, the grape skins, seeds, and stems float to the top, forming a thick layer called a “cap.” You must manage this cap to extract color and flavor. This process involves two main techniques: pump-overs and punch-downs. Your choice depends on the grape variety and the style of wine you want.

- Pump-Overs: You use a pump to move juice from the bottom of the tank over the top of the cap. This method is very versatile. You can do it gently to preserve fruit flavors or more aggressively to extract more tannins. It also helps distribute yeast and control temperature evenly.

- Punch-Downs: You use a tool to physically push the cap down into the juice. This is often seen as a softer extraction method. It works best in open-top tanks and introduces less oxygen than a pump-over. Winemakers often use punch-downs for delicate grapes like Pinot Noir.

Many winemakers combine these methods. They might use pump-overs early in fermentation and switch to punch-downs later to release sugar from intact berries.

TECHNIQUES FOR CRISP WHITE WINES

Making crisp, aromatic white wines is where stainless steel truly shines. The process is simpler because you typically press the grapes and ferment only the juice. There is no cap to manage. Your main goal is preserving delicate floral and fruit aromas.

The key to a great white wine is a cool, slow fermentation. Your tank’s cooling jacket allows you to keep the temperature low, often between 45°F and 60°F (7°C to 16°C). This slow pace prevents the yeast from producing off-flavors and protects the wine’s fresh, vibrant character.

The question “can you ferment wine in stainless steel?” is easily answered when you taste a bright, clean Sauvignon Blanc made this way. The tank’s neutral nature and precise temperature control let the grape’s true personality come through.

ADDRESSING THE DRAWBACKS

While stainless steel offers many benefits, you should consider two main points: the initial cost and how to add complexity. You can easily manage both with the right approach. This turns potential drawbacks into powerful advantages for your winemaking.

MANAGING THE INITIAL INVESTMENT

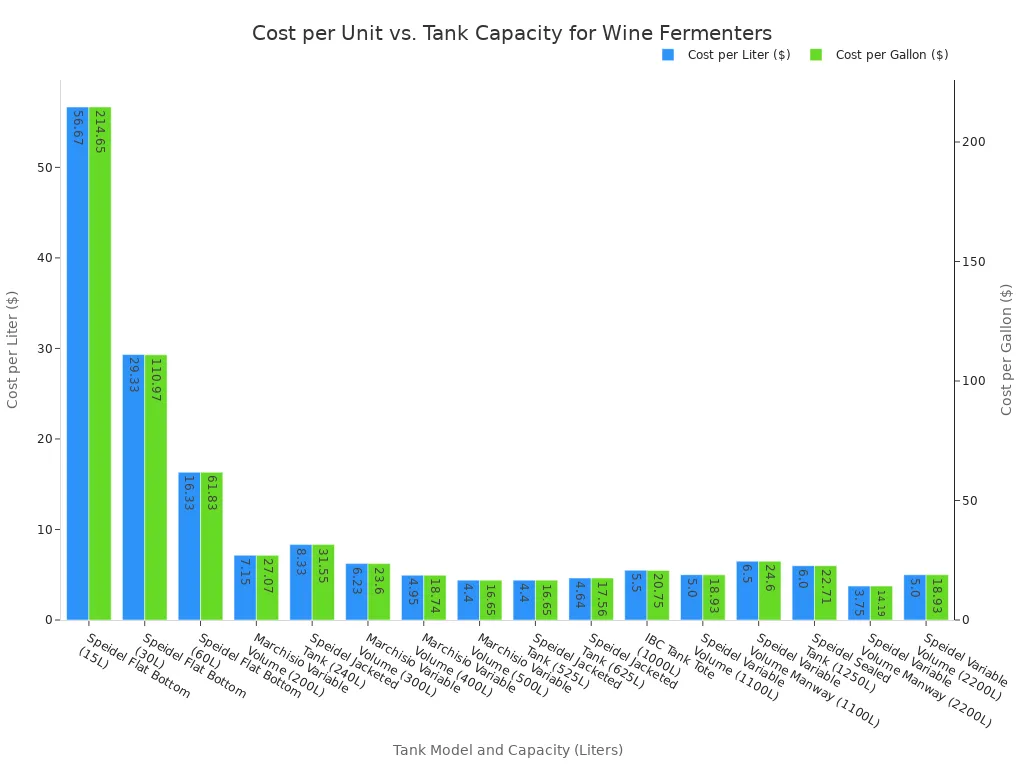

Stainless steel tanks do have a higher upfront cost than plastic or wood. You should view this as a long-term investment in quality and durability. The price per gallon often decreases as the tank size increases. This makes larger tanks a more cost-effective choice as your production grows.

A quality steel tank will last for decades. It will not scratch, stain, or absorb old flavors. This saves you money over time because you will not need to replace your equipment. The investment pays for itself through consistent, high-quality wine and operational efficiency.

ADDING COMPLEXITY AND OAK CHARACTER

Stainless steel is neutral. It does not add flavors like vanilla or spice to your wine. This is a benefit because it gives you complete control. You can add complexity and oak character precisely when and how you want.

You can easily mimic the effects of barrel aging in a steel tank. You just need to use oak alternatives and a technique called micro-oxygenation.

Here are some popular methods:

- Oak Staves, Chips, or Cubes: You can place these oak pieces inside a food-grade mesh bag. Then, you submerge the bag in your wine. Smaller pieces like chips add flavor quickly, while larger staves provide a slower, more subtle integration.

- Micro-Oxygenation: This process introduces tiny, controlled amounts of oxygen into the wine. It softens tannins and helps integrate the oak flavors, just like a barrel does. This technique gives you the power to evolve the wine inside the tank.

By combining these methods, you gain precise control over the final flavor profile. You can create a wine with all the complexity of barrel aging without the expense and hygiene risks of wood.

INNOVATIONS IN STEEL FERMENTATION

The world of winemaking is evolving. Stainless steel tanks are now at the center of this technological shift. Modern innovations turn your fermentation tank into a smart, automated partner. This technology gives you unprecedented control over your wine.

SMART TECHNOLOGY AND AUTOMATION

Smart technology brings automation directly to your winery. You can now program your tank to handle critical tasks with perfect precision. This automation improves consistency and reduces the chance of human error. Your stainless steel tank can manage the entire fermentation process for you.

Modern smart tanks often include:

- Automated systems for precise temperature control.

- Touch-screen interfaces for easy setup and monitoring.

- Wi-Fi capabilities that connect the tank to your network.

- Precision-engineered agitators for perfect mixing.

You can schedule pump-overs to run automatically at specific times. You can even program the tank to “crash” the temperature after fermentation is complete. These features ensure every batch follows your exact recipe, creating a repeatable, high-quality product every time. 🤖

REMOTE MONITORING CAPABILITIES

Smart tanks give you the freedom to monitor your wine from anywhere. You can connect to your tank using an app on your smartphone, tablet, or computer. This remote access means you are always in control, whether you are at home or away from the winery.

Imagine receiving a text message or email alert the moment your fermentation temperature goes outside its ideal range. This instant notification allows you to fix problems before they can harm your wine.

This technology provides a constant stream of data. You can track many important details in real time. You can monitor key parameters like:

- Sugar concentration (Brix)

- pH and acidity levels

- Temperature

- CO2 emissions

This continuous data logging gives you deep insights into your fermentation. You can analyze the information later to refine your process for future vintages. This level of control helps you make better wine with more confidence.

SUSTAINABILITY AND LONG-TERM VALUE

When you choose a stainless steel tank, you are making a smart decision for both the planet and your wallet. This choice offers excellent long-term value. It also supports sustainable winemaking practices. You invest in equipment that is built to last and designed to be efficient.

THE ECO-FRIENDLY BENEFITS OF STEEL

Choosing stainless steel helps you reduce your environmental impact. Unlike other materials, steel offers a sustainable path for your winemaking journey. It provides several key eco-friendly advantages. 🌎

- Durability and Waste Reduction: Your stainless steel tank will last for decades. This long life reduces waste because you do not need to replace it. This is different from oak barrels, which require harvesting trees and have a limited lifespan.

- Energy Efficiency: Many modern steel tanks include insulation. This feature helps maintain temperature with less energy, lowering your winery’s carbon footprint.

- Water Conservation: The smooth surface of steel is easy to clean. You will use less water and fewer chemicals compared to cleaning porous oak barrels.

- Recyclability: At the end of its very long life, your tank can be fully recycled. The steel can be used to create new products, which helps conserve natural resources.

CALCULATING THE RETURN ON INVESTMENT

A stainless steel tank is a significant purchase. You should think of it as a long-term investment that pays you back over time. The return on investment (ROI) comes from its durability, efficiency, and the quality it helps you produce.

You can calculate your return by looking at several factors. First, the tank’s long lifespan means you avoid the cost of replacing equipment every few years. Second, you save money on daily operations. You use less water and energy for cleaning and temperature control. Finally, the tank helps you create consistent, high-quality wine. This prevents costly spoiled batches and protects the value of your product.

Your initial investment in stainless steel pays for itself. You gain decades of reliable service, lower operational costs, and the ability to produce flawless wine year after year.

Choosing to ferment wine in stainless steel gives you definitive advantages. You gain total control over flavor purity, temperature, and hygiene. The initial investment pays you back with consistent quality and long-term efficiency.

For this year’s vintage, stainless steel is the smartest step toward professional-quality results.

This choice empowers every home winemaker to create exceptional wine. You can unlock the true potential of your grapes and elevate your craft. 🏆

FAQ

### Is stainless steel good for both red and white wines?

Yes, stainless steel is excellent for both. You can ferment red wines with skin contact or create crisp, aromatic white wines. The tank’s neutral nature and temperature control give you the flexibility to produce any style of wine you want.

### How long does a stainless steel tank last?

A quality stainless steel tank is a lifetime investment. With proper care, your tank will last for decades. It does not scratch, stain, or wear out like plastic or wood, providing incredible long-term value for your winery.

### Can you age wine in a stainless steel tank?

You can absolutely age wine in a stainless steel tank. This method preserves the wine’s fresh fruit character. For added complexity, you can introduce oak staves or use micro-oxygenation to mimic the effects of barrel aging with complete control.

### Do I really need a cooling jacket?

A cooling jacket is highly recommended for serious winemaking. It gives you precise temperature control. This prevents stuck fermentations and protects delicate aromas.

A cooling jacket is your best tool for ensuring consistent, high-quality results with every batch. 🌡️