You might wonder what the best wine fermentation tank is for your home winemaking. The answer depends on the type of wine you want to make, how much wine you plan to produce, and your budget. Some home winemakers prefer a fermenter made from glass or stainless steel because these materials offer durability and easy cleaning. Others choose plastic for its lightweight feel or oak for its unique impact on wine flavor. A good wine fermentation container should keep air out, which helps prevent spoilage. Studies show that home winemakers can achieve over 90% fermentation success when they monitor key factors like sugar and yeast nutrients in their fermenter early on. With the right information, you can confidently pick a fermenter that matches your home wine goals.

Chenma is one of the professional stainless steel wine tank manufacturers that can provide wineries with a variety of solutions. We also provide cider tank、stainless steel oil tank, ect.

Identify Your Wine Style and Batch Size

Wine Type Considerations

Choosing the right wine fermentation container starts with understanding the style of wine you want to make. Each wine type has unique requirements during the fermentation process. For example, red wines often benefit from oak barrels. Oak allows a small amount of oxygen to reach the wine, which helps develop complex flavors and smooth out tannins. This process is called micro-oxygenation. Many red wines need this step to reach their full potential. On the other hand, white and rosé wines usually need a container that keeps flavors fresh and crisp. Stainless steel tanks work well for these wines because they do not add extra flavors and help control temperature during the fermentation process.

Tip: If you want to make a fruity white wine, choose a container that keeps air out and allows you to control the temperature. For a bold red wine, consider a container that lets in a little oxygen, like an oak barrel.

You should also think about the flavors you want in your wine. Oak barrels add notes of vanilla and spice, while stainless steel keeps the wine’s natural fruit flavors. Some home winemakers use oak chips in stainless steel tanks to get the best of both worlds.

- Stainless steel tanks are great for temperature control and pure flavors.

- Oak barrels add complexity and allow for gentle oxidation.

- The container you choose will shape the final taste and aroma of your wine.

Batch Volume Needs

The amount of wine you plan to make will affect your choice of fermentation container. Larger containers, like big barrels, can improve wine quality because they have a smaller surface-to-volume ratio. This means less air touches the wine, which helps with aging. However, large barrels can be hard to handle in a home setting. Many home winemakers prefer smaller barrels, such as 55-liter sizes. These are easier to move, stack, and clean. Smaller containers also help you keep batches consistent, which is important if you want to repeat the same process for each wine style.

Regular tasting is important, especially when using oak. Smaller batches can pick up oak flavors quickly, so you need to check the wine often. Matching your batch size to your space and your wine’s needs will help you manage the fermentation process better and avoid problems like over-oaking or volume mismatches.

Note: Consistent batch sizes make it easier to transfer wine between containers and keep your process organized.

Types of Wine Fermentation Containers

When you choose a wine fermentation container, you have several types to consider. Each type of fermenter has unique features that affect your wine’s flavor, aging, and quality. Let’s look at the most common types of fermentation tanks and vessels used in home winemaking.

Plastic Fermenters

Plastic fermenters are popular for beginners. They are lightweight and cost-efficient. You can move them easily, and they come in many sizes. Improved materials have made modern plastic wine fermentation containers safer for wine. However, plastic is oxygen permeable, which means air can slowly enter the vessel. This can affect wine quality over time. Many home winemakers use plastic fermenters for the first stage of the fermentation process, then transfer the wine to another vessel for aging.

Tip: Always choose food-grade plastic for your wine fermentation vessel to avoid unwanted flavors.

Glass Carboys and Demijohns

Glass carboys and demijohns, sometimes called glazen vessels, are classic choices for home winemakers. You can see the wine as it ferments, which helps you monitor clarity and sediment. Glass does not react with wine, so it keeps flavors pure. However, cleaning these vessels can be tricky. Studies show that only glass fermenters cleaned and sanitized properly keep wine safe during aging. Avoid using abrasive brushes, as they can scratch the surface and increase contamination risk.

- Rinse with warm water right after use.

- Use a powdered brewery wash and shake well.

- Rinse thoroughly and sanitize with a sulfite solution.

Stainless Steel Wine Fermentation Tank

Stainless steel wine fermentation tanks offer durability and precise temperature control. You can use these tanks for both fermentation and wine aging. Stainless steel fermentation tanks resist corrosion and keep your wine pure by preventing chemical reactions. Market studies show that these tanks are cost-effective and easy to clean. Many wineries use double-layer jacketed tanks for temperature-sensitive wines. You can find stainless steel wine fermentation tanks in many sizes, from small home batches to large commercial volumes.

| Wine Tank Type | Features | Suitable Uses |

|---|---|---|

| Single-layer stainless steel | Simple, low cost | Short-term storage |

| Double-layer jacketed | Cooling/heating, precise temperature | Fermentation, temperature-sensitive |

| Conical bottom | Easy sediment removal, easy cleaning | Clarity improvement, fermentation |

Oak Barrels

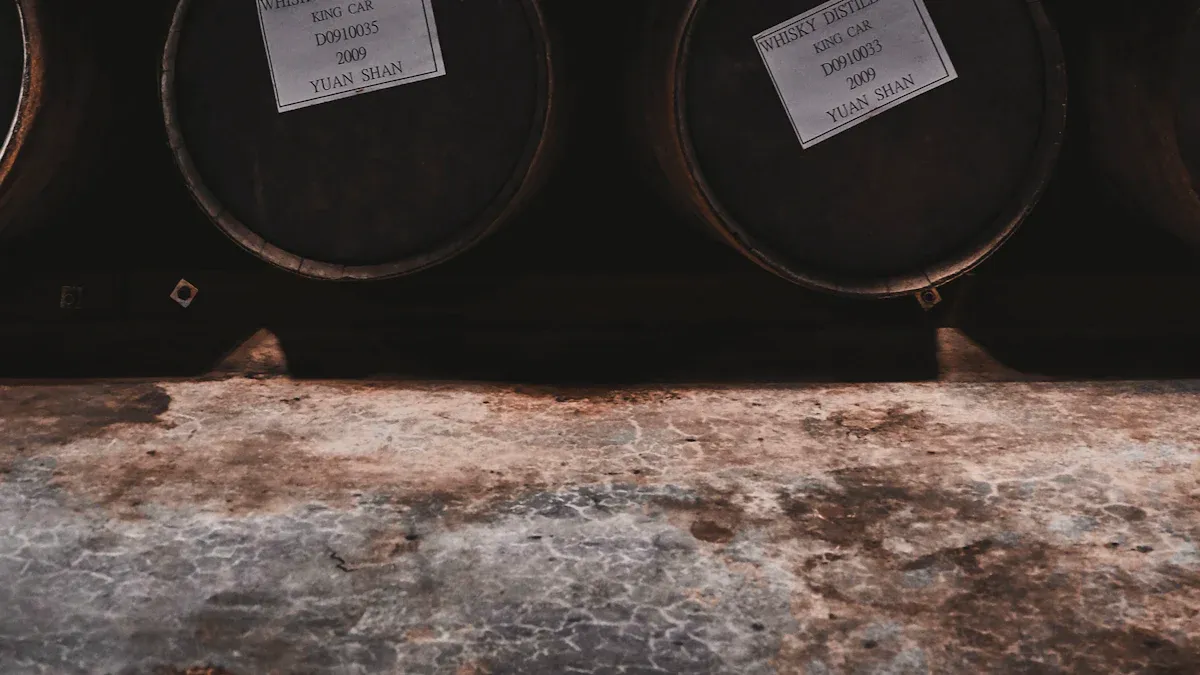

Oak barrels have a long history in winemaking. You can use them to add unique flavors and aromas to your wine. Oak barrels allow a small amount of oxygen to enter, which helps with wine aging and softens tannins. Scientific studies show that oak barrels can reduce methanol content in wine more than other types of fermentation tanks. Historical records from California wineries highlight how oak barrels give wine toasty and vanilla notes. You need to monitor temperature and cleanliness closely, as oak barrels require more care than other wine fermentation vessels. Many winemakers use oak barrels for red wines or for aging white wines to add complexity.

Note: Oak barrels are ideal for wine aging if you want to develop rich flavors and aromas.

Pros and Cons

Plastic

Plastic wine fermentation vessels offer several practical benefits. You can move them easily because they are lightweight and almost never break. This makes them a safe choice, especially if you work in a small space or need to carry your wine fermentation tank around. A clinical study compared plastic and glass fermenters and found that both types performed similarly in detecting microorganisms. Plastic bottles showed a slightly higher rate of false positives, but the difference was small. You may notice that plastic fermenters sometimes allow a bit of air to pass through, which can affect wine quality if you store wine for a long time. However, plastic remains a popular choice for beginners due to its low cost and safety.

Glass

Glass wine fermentation vessels have a long history in winemaking. You can see the wine as it ferments, which helps you monitor the process. Glass does not react with wine, so it keeps flavors pure. The table below shows the main advantages and disadvantages of glass containers:

| Advantages | Disadvantages |

|---|---|

| Airtight, prevents spoilage | Fragile and easy to break |

| Easy to sanitize | Harder to clean inside |

| Allows visual monitoring | Heavy and hard to move |

| Maintains taste and quality | More expensive than plastic |

| Good for airtight seals | Risk of thermal shock |

Using airlocks on glass jars helps keep air and contaminants out, so you do not need to open the vessel daily. This reduces the risk of mold and keeps odors down. You must watch the water level in the airlock and clean it if brine dries inside.

Stainless Steel

Stainless steel fermentation tanks stand out for their durability and control. You can clean these tanks easily, and they do not react with wine. The advantages of stainless steel fermentation tanks include precise temperature control and long-term use. Many winemakers choose this type of wine fermentation tank for both fermentation and wine aging. Stainless steel tanks also help you keep your wine pure, as they prevent outside flavors from entering. You can use them for many types of wine, and they work well for both small and large batches.

Tip: Stainless steel fermentation tanks are a smart investment if you want a reliable, easy-to-clean wine fermentation vessel for repeated use.

Oak

Oak barrels give wine unique flavors and aromas. You can use oak barrels to add notes of vanilla, spice, and toast to your wine. Oak barrels allow a small amount of oxygen to enter, which helps with wine aging and softens tannins. Studies show that oak barrels can reduce methanol content in wine and improve sensory qualities. You can also use oak chips or inserts as alternatives to traditional barrels. These options save money and reduce wine loss from evaporation. However, loose chips can clog equipment, so you may want to use bags to hold them. Most people cannot tell the difference between wine aged in oak barrels and wine aged with chips, especially after a few months. The value of oak aging depends on the grape type and your taste preferences. Oak barrels require careful cleaning and regular checks to prevent spoilage.

Note: Oak barrels work best for red wines and for adding complexity during wine aging. You can choose from different types of oak barrels or use alternatives like chips or slats to match your needs.

Material Safety

Food-Grade Standards

You need to make sure your wine fermentation container meets strict food-grade standards. These standards protect you from harmful microbes and chemicals that can spoil your wine or make it unsafe. Scientific studies show that even though most fermented foods are safe, contamination by bacteria like Salmonella or E. coli can happen if you do not use proper materials. Food-grade containers help prevent these risks.

Many countries have their own rules for food safety. These rules cover how to make, store, and use fermentation containers. The table below shows some important regulations from around the world:

| Region/Country | Regulatory Framework / Standard | Key Provisions Relevant to Fermentation Containers and Food-Grade Safety |

|---|---|---|

| India | Food Safety and Standards Act (FSSAI) | Sets science-based standards for equipment and packaging safety. |

| South Korea | Food Sanitation Act, Food Code | Covers safety for packaging and equipment used in food production. |

| China | Food Safety Law, Guobiao (GB) Standards | Focuses on preventing contamination and food poisoning. |

| European Union | General Food Law Regulation (EC No 178/2002) | Ensures food safety and puts responsibility on producers. |

| International | Codex Alimentarius Standards | Sets global hygiene and safety standards for food containers. |

Tip: Always check that your fermentation tank or vessel is labeled as food-grade and meets local safety standards.

Impact on Wine

The material of your fermentation container affects both the safety and the quality of your wine. Stainless steel, glass, and wood are common choices because they do not react with the wine or release harmful substances. European regulations require these materials to be safe for food contact, which helps protect your health.

The type of container you choose also changes how your wine tastes and ages. Scientific studies show that glass bottles keep wine fresh but have a higher environmental impact. Bag-in-box containers lower greenhouse gas emissions by up to 90% compared to glass. Stainless steel tanks help you control oxidation, which keeps the wine’s quality high. If you use the wrong material, your wine may spoil or lose its best flavors.

Note: Picking the right container helps you make wine that is both safe to drink and high in quality.

Cleaning and Maintenance

Cleaning by Material

You need to clean your fermentation container based on its material. Each type of container—plastic, glass, stainless steel, or oak—requires a different approach. Cleaning validation programs show that you must use the right cleaning agents and methods for each material to remove all residues. For example, alkaline cleaners work well for oily residues, while acidic cleaners remove mineral deposits. You should always follow cleaning steps that match your container’s needs.

- Plastic: Use mild, non-abrasive cleaners. Avoid hot water that can warp the plastic. Rinse well to remove all soap.

- Glass: Rinse with warm water right after use. Use a soft brush and a powdered cleaner. Avoid scratching the surface.

- Stainless Steel: Use a soft cloth and a cleaner made for stainless steel. Rinse with hot water. Do not use bleach, as it can damage the surface.

- Oak: Rinse with warm water only. Never use soap, as it can soak into the wood. Let the barrel dry completely before storing.

Tip: Always keep detailed cleaning records. This helps you track your process and ensures your wine stays safe.

Routine cleaning should include residue testing. This step checks if your cleaning removed all traces of wine or other substances. You should validate your cleaning process by testing under different conditions, such as temperature and cleaning agent strength. Keeping your cleaning procedures consistent and well-documented helps you avoid problems later.

Preventing Contamination

You must prevent contamination to protect your wine from spoilage. Effective cleaning and sanitizing steps include pre-rinsing, using the right cleaning solution, scrubbing, rinsing again, and drying. Choose sanitizing agents that kill germs, work with your container’s material, and leave no harmful residue.

- Clean and sanitize every container before and after use.

- Use separate tools for wine and other foods to avoid cross-contamination.

- Store containers in a clean, dry place to keep pests away.

- Test your wine for quality during and after fermentation.

Poor sanitation can lead to off-flavors, incomplete fermentation, or spoiled wine. Cleaning protocols must match the type of residue you find. For example, some deposits rinse away with water, while others need strong chemicals. You should adjust cleaning time, temperature, and chemical strength to get the best results. Regular maintenance and strict cleaning routines help you make high-quality wine every time.

Temperature Control

Temperature control plays a key role in the success of your wine fermentation process. If you keep the temperature steady, you help the yeast work at its best and avoid unwanted flavors. Changes in temperature can cause the fermentation process to slow down or speed up in ways that harm your wine. Experimental data from milk fermentation shows that keeping a constant temperature leads to steady CO2 production and stable fermentation. When the temperature shifts, the rate of fermentation changes, which can cause problems. Studies on Baijiu fermentation also show that sudden temperature rises can lead to abnormal flavors and lower quality. You want to avoid these issues by managing temperature carefully.

Insulation

Insulation helps you keep the temperature inside your fermentation container steady. Good insulation stops heat from escaping or entering too quickly. This keeps the wine at the right temperature for the yeast to do its job. Research shows that adding paraffin phase change material (PCM) to the sides and top of fermentation tanks improves thermal insulation. This method keeps the temperature close to ideal conditions and helps the fermentation process stay stable. In grape must fermentation, PCM slowed the rise in temperature and kept the average temperature lower than tanks without PCM. This means your wine stays below critical heat levels, which protects its flavor and quality.

Tip: You can use foam wraps, insulated jackets, or PCM packs to help keep your fermentation container at a steady temperature.

Monitoring

You need to monitor the temperature during the fermentation process to catch any changes early. Modern technology gives you many tools for this job. Advanced fermentation control systems let you track temperature, redox potential, and sugar levels in real time. These systems use sensors and cloud-based analytics to help you make quick adjustments. For example, a study in an Italian wine-aging room found that placing sensors in the right spots improved accuracy and saved money. The table below shows some key parameters and the tools you can use to monitor them:

| Parameter | Importance | Monitoring Technology |

|---|---|---|

| Redox Potential | Affects yeast activity and wine quality | Electrochemical redox sensors |

| Density and Brix | Tracks sugar use and guides temperature changes | Density probes |

| Fermentation Monitoring | Ensures consistent quality and process control | Integrated sensor systems |

By using these tools, you can keep your wine at the best temperature and avoid problems before they start. This careful approach helps you make high-quality wine every time.

Cost and Budget

Upfront Costs

When you choose a wine fermentation container, you need to consider the upfront costs. These costs include the price of the container, installation, and any extra equipment you might need. A comparative pricing study shows that equipment costs can vary a lot depending on the type of fermentation process. For example, semi-batch fermentation containers often cost less than batch containers. The table below shows some key cost differences:

| Cost Category | Semi-batch Process Cost ($) | Batch Process Cost ($) |

|---|---|---|

| Equipment Cost | 7,145,000 | 7,938,000 |

| Direct Fixed Capital | 43,453,000 | 48,382,000 |

| Total Plant Cost | 37,785,000 | 42,071,000 |

| Unit Production Cost ($/kg) | 22.12 | 23.10 |

You may not need to spend millions for home winemaking, but this table helps you see how costs can add up with larger or more advanced systems. When you estimate your own costs, think about the size and number of tanks you need, as well as any installation or utility expenses. Using these methods helps you match your budget and needs to the right container.

Tip: Start with a container that fits your current wine goals. You can always upgrade as your skills and production grow.

Long-Term Value

Looking at long-term value helps you make a smart investment. Some materials cost more at first but save money over time. Studies show that aluminum containers have the highest scrap value and lowest recycling costs. Glass, while popular for wine, has a low scrap value and high recycling costs, which can lead to losses if you recycle often. PET plastic falls in the middle, with moderate costs and value.

| Material | Scrap Value (cents/container) | Cost to Recycle (cents/container) | Profit (Loss) (cents/container) |

|---|---|---|---|

| Aluminum | 2.40 | 1.03 | 1.37 |

| PET Plastic | 1.08 | 1.35 | -0.27 |

| Glass | 0.08 | 2.43 | -2.36 |

If you plan to reuse your fermentation container for many batches of wine, stainless steel and food-grade plastic offer strong long-term value. These materials last for years and are easy to clean. You also save money by avoiding frequent replacements. When you think about your budget and needs, remember to include the cost of cleaning, maintenance, and recycling. Choosing the right container now can help you save money and make better wine in the future.

Space and Storage

Container Size

Choosing the right container size helps you manage your space and improve your fermentation results. You need to think about how much room you have and how the container’s shape affects the process. Engineering studies show that container dimensions can change how well your fermentation works and how easy it is to store your equipment:

- Jin et al. created a model showing that heat from fermentation links to ethanol production. The soil temperature around jars helps control heat, which is important when you use larger containers.

- Perez et al. used a two-phase model to predict the best temperature and bed height in packed bed bioreactors. They found that bigger containers can make gas flow and mixing harder, which affects how well your wine ferments.

- Jung Finkler et al. showed that you must control the temperature at the start of fermentation, especially in larger tanks, to avoid overheating.

- Wang et al. designed a rotary drum bioreactor for large-scale fermentation. Their work shows that bigger containers need careful planning for heat and oxygen control.

You should pick a container that fits your batch size and storage area. If you use a small space, choose stackable or narrow tanks. Always leave enough room around each container for cleaning and moving.

Storage Tips

Proper storage keeps your fermentation containers safe and helps them last longer. You can follow these practical tips to protect your equipment and ingredients:

| Storage Aspect | Practical Tips to Maximize Container Longevity and Safety |

|---|---|

| Dry Goods | Store in airtight containers; keep in cool (50-70°F), dry, dark places; avoid heat and pests. |

| Canned Goods | Store in cool, dry places; avoid freezing/extreme heat; keep off floor; rotate stock FIFO. |

| Perishables | Refrigerate below 40°F; separate meats; use/freeze before expiration. |

| Freezing | Use freezer-safe containers; remove air; maintain 0°F or below; label and date items. |

| General Tips | Regularly clean storage areas; rotate stock FIFO; use pest deterrents; label containers. |

- Store fermentation additives like sulfite powders in original or compatible plastic containers such as PE, PP, or PET.

- Use desiccants to keep powders dry.

- Replace sulfite powders every two years if stored cool and dry.

- Keep solutions tightly closed. Higher concentration solutions last longer.

- Label all containers with contents and dates.

- Store everything in cool, dry, and dark places to prevent spoilage.

- Use plastic lids for acids to avoid corrosion. Glass jars are safe, but metal lids may rust.

By following these guidelines, you protect your wine and equipment from damage and spoilage. Good storage habits help you make better wine and keep your workspace organized.

Choosing the Right Wine Fermentation Container

Decision Checklist

Selecting the best fermenter for your wine project can feel overwhelming. You want to make sure your choice supports both the style and quality of your wine. Use this checklist to guide your decision:

Wine Type

Decide if you plan to make red or white wine. Red wines often need open fermenters, while white wines do better in closed containers.Batch Size

Estimate how much wine you want to produce. Small batches fit well in glass carboys or demijohns. Larger batches may need stainless steel tanks or plastic bins.Flavor and Aroma Goals

Think about the flavors you want. Oak barrels add complexity and texture. Stainless steel tanks keep grape character pure. Clay pots and concrete tanks offer natural insulation and unique qualities.Budget

Set your budget. Plastic fermenters cost less and work well for beginners. Stainless steel tanks and oak barrels require more investment but last longer.Cleaning and Maintenance

Ask yourself how much time you can spend on cleaning. Glass and stainless steel are easy to sanitize. Oak barrels and clay pots need more care.Temperature Control

Consider if you need to control fermentation temperature. Stainless steel tanks allow precise control. Concrete and clay offer natural insulation.Space and Handling

Check your available space. Heavy containers like concrete tanks need strong support. Lightweight plastic or glass works well in small spaces.

Tip: Always choose a food-grade primary fermenter to protect your wine from spoilage and keep quality high.

Quick Comparison Table

The table below compares the most common fermentation containers. Use it to match your needs with the right option:

| Container Type | Advantages | Disadvantages | Best For | Key Considerations |

|---|---|---|---|---|

| Plastic Buckets and Bins | Affordable, lightweight, easy to use, versatile | Scratches easily, risk of spoilage from oxygen exposure | Budget-friendly, red wine fermentation | Careful cleaning needed, not for long-term aging |

| Glass Carboys and Demijohns | Durable, airtight, transparent for monitoring | Narrow neck, not ideal for red wine, heavy | White wine, small batches, secondary fermentation | Easy to sanitize, handle with care |

| Stainless Steel Tanks | Chemically inert, oxygen-proof, customizable, easy to clean, temperature control | Higher initial cost, may need cooling jackets | Precise control, long-term use, high quality | Great for maintaining grape character |

| Oak Barrels | Adds complex flavors, good for aging, enhances texture | Hard to clean, risk of contamination, retains pigments | Wines needing oak influence (e.g., Chardonnay, reds) | Careful maintenance, regular checks |

| Concrete Tanks | Stable temperature, customizable size and shape | Heavy, hard to clean, can harbor bacteria, higher price | Stable fermentation, traditional methods | Frequent disinfection, strong support needed |

| Clay Pots | Natural insulation, neutral flavor, promotes malolactic fermentation | Labor-intensive, difficult to maintain, expensive | Natural or organic wine, traditional winemaking | Traditional style, more effort to clean |

You can see that each fermenter has strengths and weaknesses. Home winemakers often start with plastic or glass, then move to stainless steel or oak as they seek higher quality and more control. Always match your container to your wine goals, space, and budget. This approach helps you create wine with the best possible quality and flavor.

Maintenance Tips for Fermenters

Plastic

Plastic fermenters are easy to use, but you need to care for them to keep your wine safe. Always wash your plastic fermenter with warm water and a mild, unscented soap. Avoid using hot water, as it can warp the plastic. Use a soft sponge or cloth. Scratches in plastic can trap bacteria, so check your fermenter for any damage before each use. If you see deep scratches, replace the container. Rinse the fermenter well to remove all soap. After cleaning, sanitize the fermenter with a food-safe sanitizer. Let it air dry upside down.

Tip: Store your plastic fermenter in a cool, dry place. Keep it out of direct sunlight to prevent the plastic from breaking down.

Glass

Glass fermenters keep your wine pure, but they need careful handling. Rinse your glass carboy or demijohn with warm water right after you empty it. Use a carboy brush with soft bristles to clean the inside. Avoid using abrasive pads, as they can scratch the glass. For tough stains, fill the fermenter with warm water and add a powdered brewery wash. Let it soak for a few hours, then scrub gently. Rinse several times to remove all cleaner. Sanitize with a sulfite solution before each use.

Note: Always check for chips or cracks. Damaged glass can break easily and may cause injury.

Stainless Steel

Stainless steel fermenters offer strength and easy cleaning. Wash your tank with warm water and a non-abrasive cleaner made for stainless steel. Use a soft cloth or sponge. Avoid bleach, as it can damage the metal. Rinse the tank with hot water to remove all cleaner. Sanitize with a no-rinse sanitizer. Dry the fermenter with a clean towel or let it air dry. Inspect the seals and valves for residue or buildup.

| Step | Action |

|---|---|

| Cleaning | Use warm water and stainless cleaner |

| Rinsing | Rinse with hot water |

| Sanitizing | Apply no-rinse sanitizer |

| Drying | Air dry or use a clean towel |

Oak

Oak barrels need special care to keep wine flavors fresh. Rinse the barrel with warm water after each use. Never use soap, as it can soak into the wood. Fill the barrel with hot water and let it sit for 24 hours to swell the wood and check for leaks. Empty the barrel and let it dry completely. Store the barrel with a sulfur stick or solution inside to prevent mold and bacteria. Rotate the barrel every few weeks if you store it empty.

Tip: If you notice off smells, rinse the barrel with a citric acid solution, then rinse with clean water. Always keep your barrel in a cool, humid place to prevent the wood from drying out.

Common Mistakes

When you start making wine at home, you might run into some common mistakes. These errors can affect your wine’s taste, safety, and success. Learning about these mistakes helps you avoid them and make better wine.

Material Safety Overlooked

You need to check that your fermentation container is food-grade and safe for winemaking. Some people use containers not meant for food, like old paint buckets or storage bins. These can leach harmful chemicals into your wine. The U.S. Food and Drug Administration (FDA) warns that non-food-grade plastics may contain BPA or phthalates, which can move into liquids. Stainless steel, glass, and food-grade plastic all meet strict safety standards. Always look for labels that say “food-safe” or “food-grade.” If you skip this step, you risk spoiling your wine or harming your health.

Tip: Only use containers with clear food-grade markings. If you are unsure, ask the seller or check the manufacturer’s website.

Cleaning Neglected

You must clean and sanitize your fermenter every time you use it. Skipping this step lets bacteria and wild yeast grow. These microbes can cause off-flavors, cloudiness, or even spoil your wine. A study from the American Society for Enology and Viticulture found that poor cleaning increased spoilage rates by over 30%. Use the right cleaner for your container’s material. Rinse well and sanitize before adding juice or must. Even a small amount of residue can ruin a whole batch.

- Wash with warm water and a mild cleaner.

- Rinse thoroughly.

- Sanitize with a food-safe solution.

Note: Clean tools and hands before touching your wine or equipment.

Space Misjudged

You need enough space for your fermentation setup. Many beginners pick containers that are too big or too small for their space. Large tanks may not fit through doors or on shelves. Small containers may not hold your full batch, causing spills or wasted wine. You should measure your space before buying a fermenter. Leave room for cleaning, moving, and storing your equipment.

| Mistake | Result | How to Avoid |

|---|---|---|

| Too large | Hard to move or store | Measure first |

| Too small | Overflow or wasted wine | Match batch to container |

| Poor layout | Hard to clean or access | Plan your workspace |

Planning your space saves time and prevents accidents. Always check your area before you start.

You can choose the best wine fermentation container by thinking about your wine style, batch size, and personal needs. Make sure you pick a safe material and keep your container clean. Good storage helps your wine stay fresh. Use the checklist and comparison table to guide your choice. When you select the right fermenter, you set the stage for great home wine every time. 🍇

FAQ

What is the best material for a wine fermentation container?

You should choose stainless steel or glass for most home winemaking. These materials do not react with wine. They are easy to clean and last a long time. Stainless steel also helps you control temperature.

How do I know if my container is food-grade?

Look for a label or stamp that says “food-grade” or “food-safe.” You can check the manufacturer’s website for details. Only use containers made for food or beverage use to keep your wine safe.

Can I use plastic buckets for wine fermentation?

You can use food-grade plastic buckets for primary fermentation. They are light and easy to handle. Do not use them for long-term storage. Plastic can let in air and may scratch easily.

How often should I clean my fermenter?

You should clean your fermenter after every use. Wash it with warm water and the right cleaner for the material. Always sanitize before adding new wine. This keeps your wine safe from bacteria.

Do I need to control the temperature during fermentation?

Yes, you need to keep the temperature steady. Yeast works best at certain temperatures. Too much heat or cold can spoil your wine. Use a thermometer to check the temperature often.