Choosing the right wine fermentation tanks for sale demands careful attention to both price and features. The global market for these tanks continues to expand, with the tank and fermenters segment accounting for over one-third of the wine fermentation equipment market revenue. Buyers should weigh not only cost but also quality, durability, and the reputation of the seller. Certified manufacturers like Chenma deliver tanks with advanced stainless steel construction and strict quality controls, offering long-term value and dependable performance. Comparing cost, features, and certifications ensures buyers get the best price while avoiding unnecessary expenses.

- The wine fermentation equipment market is projected to reach USD 2.10 billion by 2032, driven by rising demand and technological innovation.

Why Compare Wine Fermentation Tanks

Value

Comparing wine fermentation tanks gives buyers the best chance to maximize value for their investment. Each tank material—stainless steel, wood, or concrete—offers unique benefits and challenges. Stainless steel tanks do not add tannins or flavors, so the fruit profile of the wine stands out. These tanks are durable, easy to clean, and last for many years, which increases long-term value. Concrete tanks allow gradual oxygen flow and stable temperature, which can change the pace of fermentation and the wine’s character. Wood tanks add tannins and oak-driven flavors, but they need more maintenance and can increase the cost over time.

Buyers who compare tanks can balance quality, price, and functionality. They can look for features like cooling jackets, conical bottoms, and mobility options, which improve fermentation control and add value. Customization options, such as extra ports or polished interiors, can reduce future cost and make operations more efficient. Evaluating bundled accessories and warranty terms helps buyers avoid hidden cost and ensures better value. Reputable sellers often provide certifications and after-sales support, which protect the buyer’s investment and add value beyond the initial price.

Tip: Buyers should consider future growth. Modular and scalable tank designs allow wineries to expand efficiently, increasing the long-term value of their purchase.

Avoiding Mistakes

Failing to compare wine fermentation tanks can lead to costly mistakes. Many buyers overlook the importance of temperature control, which is crucial for proper fermentation. Some underestimate the storage space needed for equipment, leading to higher cost later. Ignoring ease of cleaning can result in contamination and ruined batches, reducing the value of the investment.

Common mistakes include:

- Choosing tanks without considering compatibility with wine styles or ingredients, which can harm wine quality and value.

- Focusing only on price or unnecessary features, instead of quality and suitability, which can increase cost and lower value.

- Buying cheap imported tanks without local support, making repairs and parts replacement difficult and costly.

- Overlooking long-term cost, such as cleaning agents and replacement parts, which reduces overall value.

- Ignoring the need for proper anchorage and seismic design, risking damage and extra cost.

Selecting tanks with the right features, certifications, and support ensures buyers avoid these pitfalls. Quality and durability, especially with stainless steel tanks, are essential for consistent wine production and lasting value.

Wine Fermentation Tanks for Sale: What to Know

Types

Buyers will find several types of wine fermentation tanks for sale, each designed for different winemaking needs. The most common options include open-top fermentation tanks, closed fermentation tanks, pump-over fermenters, and variable-capacity tanks. Open-top fermentation tanks allow winemakers to manage cap punching and oxygen exposure, which is ideal for red wines that benefit from more contact with air. Closed fermentation tanks, on the other hand, limit oxygen exposure and help preserve delicate aromas, making them suitable for white and rosé wines.

Pump-over fermenters use a system that circulates juice over the cap of grape skins, improving extraction and color. Variable-capacity tanks offer flexibility for wineries that process different batch sizes. These tanks use a floating lid to minimize oxidation, making them a popular choice for small and medium-sized producers.

The table below summarizes the main types of tanks and their features:

| Tank Type | Best For | Key Advantages |

|---|---|---|

| Open-top fermentation tanks | Red wines | Easy cap management, oxygen exposure |

| Closed fermentation tanks | White, rosé wines | Aroma preservation, less oxidation |

| Pump-over fermenters | Reds, robust whites | Enhanced extraction, color control |

| Variable-capacity tanks | Flexible batch sizes | Reduces oxidation, scalable |

Tip: Wineries should match tank type to their wine style and production goals for the best results.

Materials

The material of a wine fermentation tank affects both wine quality and the longevity of the equipment. Stainless steel wine fermentation tanks remain the industry standard due to their durability, easy cleaning, and precise temperature control. These tanks preserve the natural flavors of grapes and prevent unwanted flavors from entering the wine.

Other materials include oak, concrete, glass, fiberglass, and plastic. Oak barrels add complexity and unique flavors, but require more care and can be costly. Concrete tanks provide stable temperatures and gentle oxygen exposure, which can help with wine maturation. Glass vessels keep wine pure and stable, but work best for small batches because they are fragile. Fiberglass tanks are lightweight and easy to move, but can scratch and harbor bacteria if not maintained. Plastic tanks are affordable and suitable for small-scale or experimental batches, but may absorb flavors over time.

The following table compares the impact of different materials:

| Material Type | Impact on Wine Quality and Longevity | Key Features and Considerations |

|---|---|---|

| Stainless Steel | Preserves grape flavors, supports freshness and longevity | Durable, easy to clean, higher initial cost |

| Oak Barrels | Adds flavor complexity, supports aging | Needs maintenance, less temperature control |

| Concrete | Stable temperatures, supports maturation | Heavy, needs careful cleaning |

| Glass | Pure flavors, stable wine | Fragile, small batches only |

| Fiberglass | Lightweight, may influence aging | Can scratch, suitable for small wineries |

| Plastic | Neutral flavor, budget-friendly | Less durable, may absorb flavors |

| Variable-capacity stainless steel | Airtight, flexible batch sizes, supports freshness | Easy to clean, operational efficiency, higher cost |

Note: Stainless steel wine fermentation tanks and variable-capacity tanks offer the best combination of hygiene, durability, and operational flexibility for most wineries.

Comparing Prices of Wine Fermentation Tanks

Price Ranges

When buyers start comparing prices of wine fermentation tanks, they quickly notice a wide range of options. The price depends on the tank’s size, material, and intended use. Small tanks work well for home winemakers or experimental batches, while large tanks serve commercial wineries.

Here are some typical price ranges for different tank sizes and materials:

| Size/Capacity | Material | Typical Price Range (USD) |

|---|---|---|

| Small (around 5 gal) | Glass | $50 – $100 |

| Small (around 5 gal) | Stainless Steel | $150 – $300 |

| Medium (around 50 gal) | Plastic | $300 – $500 |

| Medium (around 50 gal) | Stainless Steel | $1,000 – $2,500 |

| Large (around 500 gal) | Stainless Steel | $5,000 – $10,000 |

| Extra Large (1,000+ gal) | Stainless Steel | $10,000 and up |

- Small stainless steel tanks (3L to 15L) usually cost between $50 and $105.

- Medium stainless steel tanks (30L to 60L) often range from $150 to $980.

- Larger stainless steel tanks (95L to 120L) are priced between $550 and $660.

Plastic tanks offer a lower price range, making them suitable for small-scale or temporary use. Used oak barrels can cost less than new stainless steel tanks but require more maintenance and have a shorter lifespan. Stainless steel tanks, while more expensive, provide superior durability and long-term value.

Note: The price range increases with tank size and material quality. Stainless steel tanks generally cost more than glass or plastic but last much longer.

Factors Affecting Price

Several factors influence the price of wine fermentation tanks. Buyers should consider these elements when evaluating wine fermentation tanks for sale:

- Material Quality: The grade of stainless steel (such as 304 or 316) affects both cost and corrosion resistance. Tanks made from 316 stainless steel cost more due to enhanced durability.

- Tank Size and Capacity: Larger tanks require more raw materials and labor, which increases the price. Commercial wineries often invest in tanks with capacities over 1,000 gallons, resulting in a higher initial cost.

- Wall Thickness and Structural Design: Thicker walls and advanced designs, like double-layer jackets or conical bottoms, add to the manufacturing cost.

- Production Process: High-precision welding, mirror polishing, and advanced sealing methods improve tank quality but raise the price.

- Functional Features: Tanks with temperature control, automatic stirring, CIP (clean-in-place) systems, and inert gas protection cost more than basic models.

- Customization: Custom-designed tanks tailored to specific winery needs increase the price. Regulatory compliance, such as FDA or CE certification, adds complexity and cost. Fully automated fermentation systems can exceed $250,000, especially with advanced customization.

- Transportation and Installation: Large tanks require special handling, which increases shipping and installation costs.

- Brand Reputation and Support: Well-known brands with strong after-sales service may charge a premium, but they offer better reliability and technical support.

| Tank Material | Price Range (USD) | Durability | Notes on Price and Value |

|---|---|---|---|

| Stainless Steel | $1,000 – $20,000 | Very High | Highest upfront cost; offers superior durability, temperature control, and flavor neutrality; long lifespan (>30 years) justifies cost |

| Plastic | $100 – $800 | Low | Most affordable; less durable; may retain odors; suitable for small batches or short-term use |

| Oak Barrels (Used) | $400 – $2,000 | Medium | Lower cost than stainless steel; requires maintenance; adds flavor; shorter lifespan (up to 8 fills) |

Tip: Customization, such as adding temperature control or automation, can significantly increase the cost. Buyers should balance desired features with their budget and production needs.

When comparing prices of wine fermentation tanks, buyers should look beyond the initial price tag. Features, size, and customization all play a role in the final cost. Stainless steel tanks may require a higher upfront investment, but their durability and low maintenance often result in a lower total cost over time. Plastic tanks offer a lower price range but may not provide the same long-term value. Used oak barrels can reduce initial cost but need more frequent replacement.

Careful evaluation of these factors helps buyers choose the right tank for their needs and budget. Understanding the full price structure ensures a smart investment in wine fermentation tanks for sale.

Key Features to Compare

Stainless Steel Grade

The grade of stainless steel plays a major role in the durability and safety of wine fermentation tanks. Most manufacturers use 304 or 316L stainless steel. Grade 304 offers strong corrosion resistance and meets food safety standards. Grade 316L provides even greater resistance to corrosion, especially in acidic environments like wine production. This higher grade helps prevent rust and extends the tank’s lifespan. Tanks made from these materials also have smooth surfaces, which makes cleaning easier and helps maintain wine purity. Choosing the right stainless steel grade protects wine from unwanted chemical reactions and supports consistent quality.

Temperature Control

Temperature control is essential for managing fermentation. The right system helps winemakers avoid off-flavors and ensures yeast works at its best. Options include cooling jackets, glycol chillers, and insulated tank walls. Thermoregulated fermenters use built-in systems to keep temperatures steady, which is critical for both red and white wines. Stable temperatures help preserve aromas and prevent spoilage. Some tanks also offer heating pads or immersion chillers for precise adjustments. These features allow wineries to create the ideal environment for each batch.

Tip: Tanks with advanced temperature control reduce the risk of stuck or slow fermentations, leading to better wine every time.

Automation

Automation brings efficiency and consistency to winemaking. Modern tanks use sensors to monitor temperature, pH, and fermentation progress in real time. Automated systems can adjust cooling or heating without manual input. This reduces human error and saves labor. Alerts notify staff if conditions change, allowing quick action to protect wine quality. Automation also helps wineries track data, making it easier to repeat successful batches and improve over time.

Certifications

Certifications show that a tank meets strict quality and safety standards. Important certifications include ISO9001 for quality management, ISO22000 for food safety, and CE for compliance with European regulations. Tanks from certified manufacturers like Chenma also meet standards for occupational health and pressure vessel safety. These certifications ensure tanks are safe, reliable, and suitable for both domestic and export markets. Buyers should always check for these marks when comparing tanks.

| Certification | What It Means for Buyers |

|---|---|

| ISO9001 | Consistent quality and reliable products |

| ISO22000 | Food safety for wine production |

| CE | Meets European safety standards |

| PED | Safe for use under pressure |

Seller Reputation

Research

Buyers should always research a seller before making a purchase. Customization options matter because every winery has unique needs. A good seller offers tailored features such as temperature control systems, oxygen management, and monitoring sensors. These features help improve fermentation quality. Buyers can consult with industry experts or suppliers who provide personalized advice. This step ensures the chosen tanks fit production volumes, space, and winemaking style. Careful research helps buyers avoid costly mistakes and select the right equipment for their operation.

Reviews

Customer reviews play a key role in the decision-making process. They help buyers compare different fermentation tank models and prices. Online marketplaces allow buyers to read feedback from other customers. Reviews highlight product quality and the reliability of the seller. Positive reviews, along with certifications, confirm the reputation of the manufacturer. Buyers should look for sellers with a strong track record of safety, quality, and durability. Reviews also help buyers focus on quality and suitability, not just price.

- Customer reviews support trust in the seller and their products.

- Reviews help buyers assess product quality and manufacturer reliability.

- Buyers can use reviews to prioritize durability and suitability.

Support

A reputable seller provides more than just equipment. They offer technical support and after-sales service. This includes help with installation, troubleshooting, and maintenance. For example, some sellers provide free replacement parts during the warranty period and lifelong technical advice. Comprehensive support reduces downtime and keeps operations running smoothly. Buyers should expect scheduled maintenance services, repair, and warranty coverage. The table below shows what buyers can expect from a reputable seller:

| Service Type | What to Expect |

|---|---|

| Technical Support | Installation, troubleshooting, advice |

| Maintenance | Scheduled checks, part replacement |

| Warranty | Free parts, clear terms |

| Documentation | Manuals, technical bulletins |

Choosing an experienced seller like Chenma, with strong certifications and technical support, ensures long-term value and dependable service.

Requesting Quotes

Specifications

When buyers request quotes for wine fermentation tanks, they should give suppliers clear and detailed information. This helps suppliers offer an accurate price and prevents surprises later. Buyers should list the tank capacity they need, such as the production volume and batch size. They should describe important features, like jacketing for temperature control, the type of bottom (flat or conical), and whether they want variable capacity. Material grade matters as well. Buyers should state if they prefer 304 or 316 stainless steel, since this affects both durability and cost. Customization is common in winemaking. Buyers should mention any special port configurations, finishing, or fittings they need. Accessories like tank stands, sample valves, cooling jackets, thermometers, and pump over systems should also be included in the request. Giving these details ensures the supplier can match the tank to the buyer’s needs and provide a fair price.

Tip: A detailed quote request helps avoid missing features or unexpected costs later.

Warranty

Warranty terms play a key role in the buying process. Buyers should ask about the length of the warranty and what it covers. Some suppliers offer free replacement parts or repairs during the warranty period. Others may include technical support or training. A strong warranty protects the buyer from extra cost if something goes wrong. Buyers should also check if the warranty covers both the tank and any accessories. Clear warranty terms add value and make the price easier to compare between suppliers.

Hidden Costs

Hidden costs can affect the total price of a wine fermentation tank. Buyers should ask suppliers to list all possible charges. These may include shipping, installation, taxes, and fees for custom features. Sometimes, accessories or spare parts are not included in the initial price. Buyers should also check for ongoing costs, such as maintenance or cleaning supplies. By asking about these items up front, buyers can avoid budget surprises and make a better decision.

- Always request a full breakdown of costs in the quote.

- Ask if the price includes delivery and installation.

- Check for extra charges on accessories or customizations.

Note: Understanding all costs before buying helps wineries stay within budget and avoid unexpected expenses.

Balancing Price and Value

Durability

Durability stands as a key factor when buyers weigh price against value in wine fermentation tanks. Stainless steel tanks may have a higher initial price, but their long lifespan and resistance to corrosion deliver strong value over time. These tanks often last decades with minimal wine loss, which reduces replacement cost and supports consistent production. In contrast, oak barrels and concrete tanks might seem less expensive at first, but they require more frequent replacement and maintenance. Buyers who focus on durability often find that a higher upfront price leads to greater value and lower total cost in the long run.

Buyers should always consider both the immediate price and the long-term value that durable tanks provide.

Maintenance

Maintenance requirements can greatly affect both the cost and value of a wine fermentation tank. Stainless steel tanks offer easy cleaning and low maintenance, which saves time and reduces ongoing cost. Oak barrels need careful cleaning, humidity control, and regular replacement, which increases both cost and effort. Concrete and clay tanks require special cleaning methods and frequent inspections. The table below compares maintenance needs for different tank types:

| Tank Type | Maintenance Requirements |

|---|---|

| Stainless Steel | Easy to clean; corrosion-resistant; regular checks for leaks and scratches |

| Oak Barrels | Gentle cleaning; maintain humidity; periodic replacement |

| Concrete Tanks | Avoid strong chemicals; inspect for cracks; control environment |

| Clay Vessels | Labor-intensive cleaning; sensitive to hot water; careful sanitization |

Choosing a tank with low maintenance needs increases value by reducing both downtime and cost.

Resale

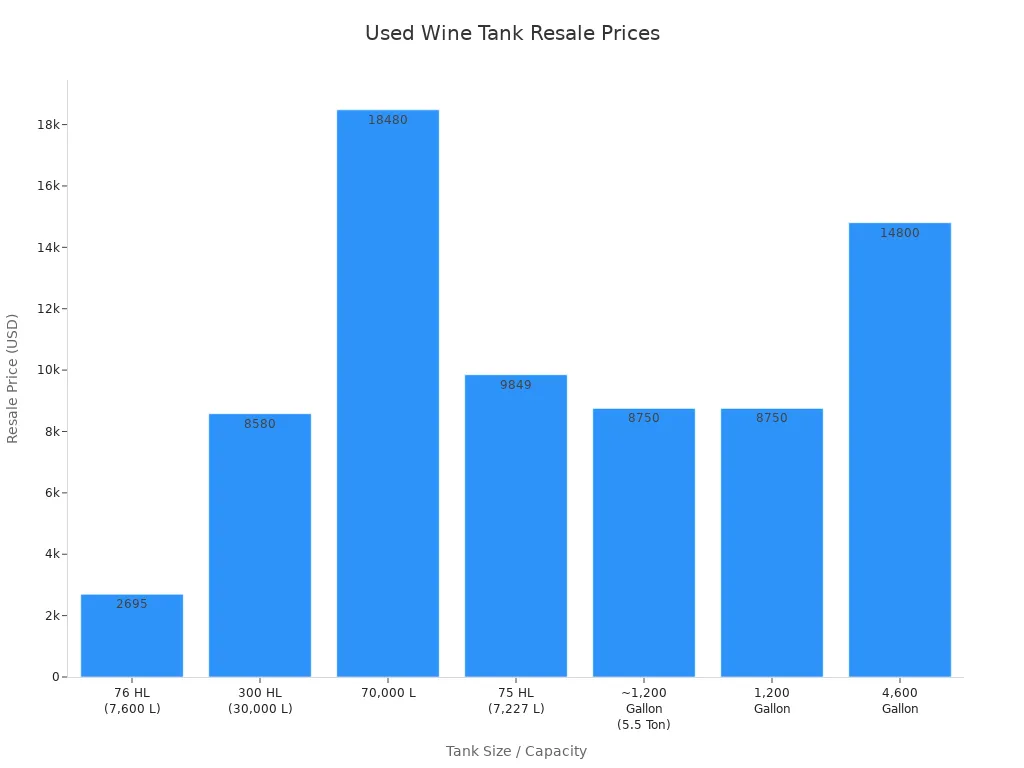

Resale value also plays a role in balancing price and value. Stainless steel tanks from reputable brands often retain a high resale price, making them a smart investment. For example, used stainless steel tanks with capacities from 7,600 liters to 70,000 liters can sell for $2,695 to $18,480, depending on brand and condition. Tanks from brands like Arsilac and Criveller show strong resale value in the secondary market.

Buyers who plan for future upgrades or changes in production can recover part of their initial cost by selling used tanks. This adds to the overall value and helps offset the original price.

A structured approach that considers durability, maintenance, and resale ensures buyers achieve the best balance of price and value.

Practical Buying Tips

Budget

Setting a clear budget helps buyers avoid overspending on wine fermentation tanks. They should start by selecting tank materials that match their wine production needs. Stainless steel offers excellent durability and corrosion resistance, but it comes at a higher price. Polyethylene tanks cost less and work well for less corrosive applications. Buyers must evaluate tank size carefully. Oversized tanks increase the price and waste space, while undersized tanks create inefficiencies. Factoring in long-term value is essential. A higher initial price for quality materials and features often reduces future expenses. Buyers should also account for maintenance and operating costs, such as energy use, cleaning supplies, and compliance with safety regulations. This approach prevents unexpected financial burdens and ensures the total price stays within budget.

Tip: Always compare the total price, including installation and maintenance, not just the upfront cost.

Future Needs

Planning for future production growth saves money and time. Buyers should assess current batch sizes and select tank sizes that fit both present and future needs. Choosing modular tank designs allows easy expansion without disrupting existing operations. Facility space must be measured to ensure tanks fit and leave room for growth. Infrastructure, such as foundations, cooling systems, and drainage, should be sized for future capacity. Pre-installing anchor points and extra ports for cleaning and control systems makes adding new tanks simple. Buyers should also reserve electrical and drainage capacity for new equipment. Consulting experienced suppliers helps align tank features with long-term production goals. This strategy keeps the price manageable as the business grows.

- Reserve space for expansion.

- Size cooling and drainage systems for future needs.

- Invest in scalable infrastructure first, then add tanks in phases.

Negotiation

Negotiation plays a key role in securing the best price and value. Buyers should request detailed quotes that break down all costs, including accessories, installation, and delivery. Comparing offers from multiple suppliers helps identify the most competitive price. Buyers can leverage knowledge of features, certifications, and after-sales support to negotiate better terms. Asking for discounts on bulk orders or bundled accessories often reduces the final price. Clear communication about requirements and expectations leads to more favorable deals. A well-negotiated purchase ensures buyers receive quality tanks at a fair price, supporting long-term success.

Note: Strong negotiation skills help buyers maximize value and minimize the total price paid for wine fermentation tanks.

Buyer’s Checklist

Steps

A structured approach helps buyers make informed decisions when selecting wine fermentation tanks. The following steps guide buyers through the process:

Define Production Needs

Buyers should calculate current and future wine production volumes. This step ensures the selected tank size matches both immediate and long-term requirements.Select Tank Type and Material

Buyers must choose the tank type—open-top, closed, or variable-capacity—based on wine style. Stainless steel remains the preferred material for durability and hygiene.List Essential Features

Buyers should identify must-have features such as temperature control, automation, and cleaning systems. Certifications like ISO9001 and CE indicate quality and safety.Research Sellers

Buyers need to investigate manufacturer reputation. They should check for certifications, customer reviews, and after-sales support. Companies like Chenma provide strong technical backing and proven quality.Request Detailed Quotes

Buyers should ask for itemized quotes. The quote must include tank specifications, warranty terms, delivery, and installation costs.Compare Offers

Buyers should compare quotes, features, and support services. They must weigh initial price against long-term value.

Tip: Buyers who follow a checklist reduce the risk of missing important details and avoid costly mistakes.

Questions

Before finalizing a purchase, buyers should ask key questions to clarify all aspects of the deal:

- What stainless steel grade does the tank use (304 or 316L)?

- Does the tank include temperature control and automation options?

- Which certifications does the manufacturer hold (ISO, CE, PED)?

- What warranty terms and after-sales support are provided?

- Are delivery, installation, and accessories included in the price?

- Can the tank be customized for specific production needs?

- How easy is the tank to clean and maintain?

- What is the estimated lifespan and resale value of the tank?

| Question | Why It Matters |

|---|---|

| What certifications does the tank have? | Ensures safety and quality standards |

| Is technical support available post-purchase? | Reduces downtime and protects value |

| Are there hidden costs in the quote? | Prevents budget overruns |

Buyers who ask these questions gain confidence and clarity, leading to a successful investment in wine fermentation tanks.

Common Pitfalls

Total Cost

Many buyers focus only on the sticker price of wine fermentation tanks. They often overlook the total cost of ownership. This mistake can lead to budget overruns and unexpected expenses. The total cost includes not just the purchase price, but also shipping, installation, maintenance, and energy use. For example, a stainless steel tank may cost $5,000 upfront. Shipping and installation can add another $1,000 to $2,000. Maintenance supplies and cleaning agents may cost $200 to $500 per year. Energy costs for temperature control systems can reach $300 annually.

Tip: Always ask for a full cost breakdown from the seller. This helps avoid surprises and keeps the project within budget.

A table can help buyers visualize the total cost:

| Cost Component | Estimated Amount (USD) |

|---|---|

| Purchase Price | $5,000 |

| Shipping & Installation | $1,500 |

| Annual Maintenance | $350 |

| Energy (per year) | $300 |

| Accessories | $400 |

Ignoring these extra costs can make a tank seem cheaper than it really is. Buyers who plan for all expenses make smarter investments.

Compatibility

Compatibility issues can cause major problems after purchase. Buyers must ensure the tank fits their facility and production process. Tank size, shape, and connection ports must match existing equipment. For example, a tank that is too tall may not fit under the ceiling. Ports that do not match hoses or pumps can delay production.

- Check tank dimensions against available space.

- Confirm that fittings and valves match current winery equipment.

- Review electrical and drainage requirements.

Note: Incompatible tanks can lead to costly modifications or downtime.

Some buyers forget to check local regulations. Certain regions require tanks to meet specific safety or environmental standards. Certified manufacturers like Chenma provide tanks that comply with ISO and CE standards, reducing the risk of regulatory issues.

Buyers who verify compatibility before purchase avoid delays, extra costs, and production setbacks.

Smart buyers compare both price and features when evaluating wine fermentation tanks for sale. They focus on long-term value, certifications, and the reputation of the seller. Using the checklist and practical tips helps buyers make confident decisions. Certified manufacturers like Chenma offer quality tanks and strong support. Careful research leads to better investments and reliable wine production.

FAQ

What is the best material for wine fermentation tanks?

Stainless steel stands out as the top choice. It resists corrosion, supports easy cleaning, and maintains wine purity. Many wineries prefer 304 or 316L stainless steel for its durability and food safety. Certified manufacturers like Chenma use these grades for reliable, long-lasting tanks.

How often should wineries clean fermentation tanks?

Wineries should clean tanks after every batch. Regular cleaning prevents contamination and preserves wine quality. Stainless steel tanks simplify this process. Many producers use CIP (Clean-In-Place) systems for efficiency. Proper cleaning routines help maintain certifications and extend tank lifespan.

Do wine fermentation tanks require certifications?

Yes, certifications matter. Tanks should meet ISO9001 for quality, ISO22000 for food safety, and CE for European standards. Certified tanks ensure safety, reliability, and regulatory compliance. Chenma tanks hold these certifications, giving buyers confidence in their investment.

Can wineries customize fermentation tanks?

Absolutely. Many manufacturers, including Chenma, offer custom options. Buyers can request specific sizes, ports, temperature controls, or automation features. Customization helps wineries match tanks to their production needs and facility layout. Always specify requirements when requesting a quote.