When you select tanks stainless for agriculture, you need to focus on durability, hygiene, chemical compatibility, design, sustainability, cost, safety, and supplier. Stainless steel tanks last from 15 up to 50 years with proper care. Studies show that tanks stainless, especially those made with 18Cr8Ni, resist corrosion better than other materials. These advantages of stainless steel matter for irrigation and farming. The benefits of stainless steel tanks help you store water, chemicals, or food safely. Choosing the right steel tank depends on your needs. Always check the factors to consider when choosing a steel tank, so you get the best results.

Chenma is one of the professional stainless steel wine tank manufacturers that can provide wineries with a variety of solutions. We also provide chemical mixing tank、cider tank, ect.

Durability

Corrosion Resistance

When you choose stainless steel tanks for agriculture, you get strong protection against corrosion. Stainless steel forms a thin, invisible layer of chromium oxide on its surface. This layer repairs itself if scratched, so your tank stays protected. You often see grades like AISI 304 and 316 used in agriculture. Grade 316 has extra molybdenum, which helps when you store acids or chemicals. This makes stainless steel tanks a smart choice for water, fertilizer, or chemical storage.

Corrosion happens when metal reacts with water, air, or chemicals. In farming, tanks face harsh conditions. Stainless steel tanks resist these attacks better than mild steel or poly tanks. The chromium in stainless steel, usually between 12% and 18%, forms a shield that stops rust and damage. Even if you use your tank for biogas or liquid fertilizer, the corrosion resistance keeps your storage safe and clean. You can also use passivation treatments, like nitric acid or electropolishing, to keep the protective layer strong after welding or repairs.

Tip: Always check that your stainless steel tank has the right grade for your storage needs. This helps prevent corrosion and keeps your tank working for years.

Service Life

Stainless steel tanks last much longer than other types of tanks. You can expect a stainless steel tank to provide reliable storage for 30 years or more. Some tanks still look new after decades of use. Painted steel tanks may only last about 7 to 15 years before you need to replace them. Poly tanks often last just 3 to 5 years.

Here is a quick comparison:

| Tank Material | Average Lifespan | Notes |

|---|---|---|

| Stainless Steel | 30+ years | Corrosion resistant, easy to clean, long-lasting |

| Mild Steel | 7 years | Prone to corrosion, shorter lifespan |

| Poly Tanks | 3-5 years | Material breaks down faster |

Stainless steel tanks save you money and time because you do not need to replace them often. Their durability means less maintenance and fewer repairs. You get peace of mind knowing your storage is safe, clean, and reliable. Stainless steel tanks also keep their strength and shape, even after many years in tough farm environments.

Hygiene

Easy Cleaning

You want your tanks to stay clean with minimal effort. Stainless steel tanks make this possible. The smooth, non-porous surface of stainless steel prevents dirt and residue from sticking. You can remove food particles and other debris quickly. Cleaning stainless steel tanks takes less time and uses less water compared to other materials. This helps you maintain high cleanliness standards in your food preparation and storage areas.

Take a look at how stainless steel compares to other tank materials for cleaning efficiency:

| Parameter / Material | Reduction in Microbial Surface Coverage | Notes |

|---|---|---|

| Shear stress on stainless steel | 98% reduction in L. monocytogenes | Removes microbes without chemicals |

| Sanitizer use on stainless steel | Up to 0.93 log reduction in L. monocytogenes | High sanitation with sanitizer |

| Sanitizer use on Buna-N rubber | 0.22 to 0.65 log reduction | Less effective than stainless steel |

| Sanitizer use on cement and epoxy | Never exceeded 0.38 log reduction | Lower efficacy than stainless steel |

| Mechanical treatment on HDPE/Buna-N | Significant reduction, but more surviving cells | Stainless steel outperforms these materials |

This table shows that stainless steel tanks allow you to achieve better cleanliness with less effort. You can reduce microbial contamination by up to 98% using mechanical cleaning alone. When you use sanitizers, stainless steel tanks show even greater reductions in bacteria. This means you spend less time cleaning and more time focusing on your food production.

Tip: Regular cleaning of your stainless steel tank not only improves cleanliness but also boosts operational efficiency.

Contamination Prevention

You need to prevent contamination in your tanks to protect your food and water supplies. Stainless steel tanks help you achieve this goal. The non-porous surface of stainless steel stops bacterial growth and keeps contaminants out. Unlike concrete tanks, which can develop mold and mildew, stainless steel tanks resist these problems. Plastic tanks may crack or leak, but stainless steel tanks stay strong and sealed.

A recent ENFIT study in 2024 showed that stainless steel tanks remain hygienic when you follow proper cleaning programs. Longer cleaning cycles, such as 85 minutes, remove more protein residue and bacteria. Visual checks are not enough. You should use microbiological and protein swab tests to confirm cleanliness. This approach ensures your tanks meet strict hygiene standards for food and water storage.

Here are some steps you can take to prevent contamination in your stainless steel tanks:

- Clean your tank thoroughly after each use to avoid cross contamination, which can ruin entire batches of food.

- Use specialized nozzles for cleaning. Static nozzles work for light soils, while gear-driven nozzles handle heavy soils.

- Place nozzles correctly to cover all tank surfaces and prevent spray shadows.

- Use simulation software like TankClean to optimize nozzle placement and improve cleaning results.

By following these steps, you keep your stainless steel tanks safe for food and water storage. You protect your operation from costly contamination and maintain high standards of cleanliness.

Chemical Compatibility

Steel Grades

You need to choose the right stainless for your agricultural tanks. Not all stainless works the same way. Each stainless steel grade has unique properties that affect how it handles chemicals. Stainless comes in several types: austenitic, ferritic, and duplex. These types have different levels of corrosion resistance and strength.

Austenitic stainless, like Grade 316, contains nickel and molybdenum. This mix gives it strong corrosion resistance, especially in environments with chlorides. You often see Grade 316 used for storing fertilizers or pesticides. Ferritic stainless, such as Grade 430, offers moderate corrosion resistance. It works well for milder chemicals or when you store water with low salt content. Duplex stainless, like Grade 2205, combines the best features of austenitic and ferritic types. It gives you high strength and excellent corrosion resistance. This makes it a top choice for tanks that hold harsh chemicals or face tough farm conditions.

Note: Always match the stainless steel grade to the chemicals you plan to store. This step protects your tank and keeps your operation safe.

Application Fit

You must think about how your tank will be used. The right stainless depends on the chemicals you store and the environment on your farm. Some chemicals cause more corrosion than others. For example, fertilizers with high chloride levels can attack many metals. Stainless tanks with the right grade resist this corrosion and last longer.

Here are some common choices for chemical storage:

- Duplex stainless (Grade 2205): Handles high-pressure and chloride-rich environments. You find it in pressure vessels and piping.

- Austenitic stainless (Grade 316): Resists pitting and crevice corrosion. It works well for storing chemicals with lots of chlorides.

- Ferritic stainless (Grades 430, 409): Used for milder chemicals or when exposed to nitric acid.

| Stainless Type | Example Grade | Corrosion Resistance | Common Use Cases |

|---|---|---|---|

| Austenitic | 316 | High | Fertilizer, pesticide storage |

| Ferritic | 430, 409 | Moderate | Water, mild chemicals |

| Duplex | 2205 | Very High | Harsh chemicals, pressure vessels |

You should always check the chemical composition and the environment before choosing your stainless tank. Stainless tanks protect your chemicals from corrosion, keep your farm safe, and help you avoid costly leaks or failures.

Stainless Steel Tanks: Design

Size Options

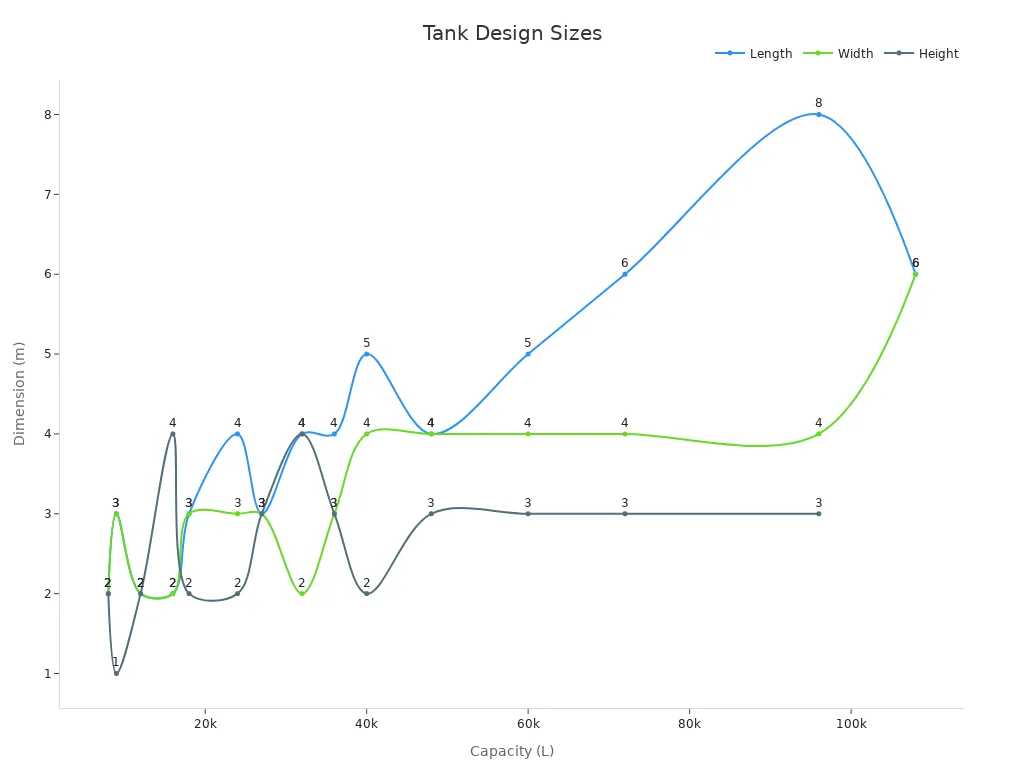

You need to choose the right size and capacity for your stainless steel tanks. The size of your tank affects how much water, fertilizer, or chemicals you can store. Stainless steel tanks come in many shapes and sizes, so you can match them to your farm’s needs. Some tanks hold as little as 8,000 liters, while others reach up to 108,000 liters. You can see the range of options in the table below:

| Tank Model | Capacity (liters) | Length (meters) | Width (meters) | Height (meters) |

|---|---|---|---|---|

| SQV – 8,000L | 8,000 | 2 | 2 | 2 |

| SQV – 9,000L | 9,000 | 3 | 3 | 1 |

| SQV – 12,000L | 12,000 | 2 | 2 | 2 |

| SQV – 16,000L | 16,000 | 2 | 2 | 4 |

| SQV – 18,000L | 18,000 | 3 | 3 | 2 |

| SQV – 24,000L | 24,000 | 4 | 3 | 2 |

| SQV – 27,000L | 27,000 | 3 | 3 | 3 |

| SQV – 32,000L | 32,000 | 4 | 2 | 4 |

| SQV – 36,000L | 36,000 | 4 | 3 | 3 |

| SQV – 40,000L | 40,000 | 5 | 4 | 2 |

| SQV – 48,000L | 48,000 | 4 | 4 | 3 |

| SQV – 60,000L | 60,000 | 5 | 4 | 3 |

| SQV – 72,000L | 72,000 | 6 | 4 | 3 |

| SQV – 96,000L | 96,000 | 8 | 4 | 3 |

| SQV – 108,000L | 108,000 | 6 | 6 | 3 or 6 |

You can also view how tank dimensions change with capacity in this chart:

When you select tanks stainless, always consider your daily storage needs and available space. The right size and capacity help you avoid shortages or wasted space. Stainless steel tanks give you flexibility, so you can expand your operation as your needs grow.

Fittings

The fittings on your stainless steel tanks play a big role in how well your tank works. You want fittings that match your application and make your tank easy to use and maintain. Here are some important fitting features to look for:

- Tank bottom designs, such as flat, dish, or cone, affect how well your tank drains and how materials flow out. Good drainage is important for keeping your tanks clean and ready for the next use.

- The grade of stainless, like 304 or 316, changes how well your tank resists corrosion. Choose the right grade for your chemicals and environment.

- Wall thickness matters for safety. Thicker walls help your tank handle higher pressure and different liquids.

- Insulated jackets and special jacketing styles, such as dimple or half-pipe coil, help you control temperature. This is important if you store temperature-sensitive products.

- Fittings that meet ASME standards and custom designs make your tanks work better with your other equipment.

- Maintenance-friendly features, like easy-access ports, help you keep your tank in top shape and reduce downtime.

Tip: Always match your tank fittings to your operation’s needs. The right fittings improve performance, safety, and reliability for your stainless steel tanks.

Tanks Stainless: Environmental Impact

Recyclability

You help protect the environment when you choose stainless tanks for agriculture. Stainless is 100% recyclable. After many years of use, you can recycle the entire tank. This process saves resources and reduces waste. Stainless tanks do not lose strength or corrosion resistance after recycling. Manufacturers often use recycled stainless to make new tanks, which lowers the need for raw materials.

Stainless tanks last for decades. When you finally retire a tank, recycling keeps valuable metals in use. This cycle supports a cleaner planet. Many companies now focus on using recycled stainless in their products. You also benefit from a tank that does not break down or release harmful chemicals into the soil or water. Unlike some plastics or mild steel, stainless resists corrosion and does not pollute the environment.

Note: Stainless tanks support eco-friendly farming by reducing landfill waste and promoting a circular economy.

Eco Standards

You want your farm to meet high environmental standards. Stainless tanks help you reach this goal. Chenma manufactures tanks stainless in a facility certified to ISO14001-2015. This certification proves that the company follows strict environmental management practices. The production process uses eco-friendly methods and materials. Manufacturers reduce carbon footprints by using recycled stainless and green energy.

Stainless tanks meet international safety and hygiene regulations. They pass seismic and pressure tests to ensure structural integrity. The materials do not react with stored contents, so you avoid contamination. Stainless tanks also comply with United Nations and Department of Transportation standards for safe transport of hazardous materials.

- Key eco-friendly features of stainless tanks:

- 100% recyclability

- Use of recycled stainless in manufacturing

- Resistance to corrosion, which prevents leaks and pollution

- Compliance with global safety and environmental regulations

- Green manufacturing processes that lower carbon emissions

You gain peace of mind knowing your tanks support both your operation and the environment. Stainless tanks help you meet government rules and protect your land for future generations.

Cost and Value

Initial Cost

When you look at the price of tanks for agricultural storage, you might notice that stainless steel tanks often have a higher initial cost. Small stainless tanks can start around $500, while large tanks may reach $50,000 or more. In comparison, plastic tanks usually have a lower upfront price, but large plastic tanks can still cost over $100,000. Concrete tanks also require a high investment, especially when you add installation and site preparation.

Here is a table to help you compare the main features of different tank materials:

| Feature | Stainless Steel Tanks | Plastic Tanks | Concrete Tanks |

|---|---|---|---|

| Initial Cost | Higher initial investment | Lower initial cost | High initial cost |

| Durability | High durability, long lifespan | Lower durability, frequent replacement | High durability but prone to cracking |

| Maintenance | Low maintenance required | High maintenance due to wear and contamination | Moderate maintenance, costly repairs |

| Hygiene | Excellent hygiene, easy to clean | Average hygiene, prone to bacterial contamination | Good hygiene |

| Long-term Cost-effectiveness | Cost-effective due to durability and low maintenance | Higher overall cost due to replacements | High maintenance costs |

| Environmental Impact | Sustainable and recyclable | Non-sustainable | Non-sustainable |

You pay more at first for stainless steel tanks, but you get a product that lasts much longer. The strong stainless material resists damage and keeps your storage safe for many years. You also avoid frequent replacements, which can add up over time.

Tip: Think about the total value, not just the purchase price. Stainless tanks give you better results in the long run.

Maintenance Savings

Stainless steel tanks help you save money on maintenance. The smooth stainless surface makes cleaning easy and prevents buildup inside the tank. You spend less time and money on repairs because stainless tanks resist corrosion and cracking. Plastic tanks often need more repairs due to leaks or damage. Concrete tanks can crack and require costly fixes.

You also reduce the risk of contamination in your storage. Stainless tanks keep your water, chemicals, or food safe. This means you do not lose valuable products to spoilage or leaks. Over the years, the savings from fewer repairs and less downtime add up. Many farmers find that stainless steel tanks pay for themselves through lower maintenance costs and longer service life.

When you choose stainless tanks for your storage needs, you invest in reliability and peace of mind. You protect your operation and get the best value for your money.

Safety and Compliance

Certifications

You want your tanks to meet the highest safety standards. Stainless tanks from trusted suppliers like Chenma come with important certifications. These include ISO9001, OHSAS18001, and EU CE. Each certification shows that the tanks follow strict rules for quality, safety, and the environment.

- ISO9001 means the stainless tanks are made with strong quality management. This helps you get tanks that are safe and reliable every time.

- OHSAS18001 focuses on worker health and safety during the tank’s production. You know the tanks are made in a safe workplace.

- EU CE certification proves the stainless tanks meet European safety and environmental rules. This gives you confidence that your tanks will perform well in tough farm conditions.

Stainless tanks also meet other global standards like NSF/ANSI 61 and WRAS. These standards make sure your tanks are safe for storing water, animal feed, and fertilizers. The tanks use high-quality 304 and 316L stainless, which gives you strong corrosion resistance and long-lasting performance.

| Certification | Impact on Stainless Steel Tank Reliability and Safety |

|---|---|

| ISO9001 | Ensures consistent quality and food safety, supporting tank reliability. |

| EU CE | Guarantees compliance with strict safety and environmental standards. |

| OHSAS18001 | Protects worker safety during manufacturing. |

Leak Prevention

You need tanks that keep your water and chemicals safe. Stainless tanks use seamless construction and advanced welding. This design stops leaks and keeps your stored materials secure. The non-porous surface of stainless prevents bacteria and dirt from getting inside. You protect your crops and animals from contamination.

Stainless tanks resist harsh weather and chemicals. They do not crack or break down like other materials. You get peace of mind knowing your tank will not leak, even after years of use. Many stainless tanks include double-wall construction for extra safety. This feature adds another layer of protection against leaks.

- Stainless tanks go through rigorous testing before they reach your farm.

- Predictive maintenance, supported by certifications, can cut unplanned downtime by up to 50%.

- Customizable designs and insulation options help you adapt your stainless tanks to any farm environment.

Tip: Always check for certifications and leak prevention features when you choose a stainless tank. These details keep your operation safe and efficient.

Steel Tank Customization

Custom Engineering

You may need tanks that fit your farm’s unique needs. Custom engineering gives you the power to design stainless steel tanks that match your operation. You can choose the exact size, shape, and features for your tank. Some farms need tanks with special insulation to keep liquids at the right temperature. Others need tanks with extra-thick walls for high-pressure storage. You can add custom fittings, such as special valves or access ports, to make cleaning and filling easier.

Engineers use advanced software to design each steel tank. They check every detail, from the thickness of the stainless walls to the placement of nozzles. This careful planning helps your tanks last longer and work better. You can ask for tanks with special coatings or finishes if you store chemicals that need extra protection. Custom engineering also lets you add safety features, like ladders or railings, to your tanks. You get a tank that fits your farm, your storage needs, and your safety rules.

Tip: Share your farm’s daily routine and storage challenges with your supplier. This helps engineers design the best stainless steel tanks for you.

Turnkey Solutions

You save time and effort when you choose turnkey solutions for your tanks. A turnkey solution means you get everything you need, from design to installation. The supplier handles each step, so you do not have to manage different companies for your tanks. You get a single point of contact for your stainless steel tanks project.

Turnkey solutions often include:

- Site assessment and planning

- Custom tank design

- Manufacturing of each tank in a controlled facility

- Delivery and installation on your farm

- Testing and quality checks

- Training for your team on tank use and maintenance

This approach helps you avoid delays and mistakes. You get tanks that are ready for use as soon as they arrive. Turnkey solutions also make it easier to expand your storage in the future. You can add more tanks or upgrade your system without starting from scratch.

A good supplier will support you after installation. You can ask for help with tank cleaning, repairs, or upgrades. This support keeps your tanks working well for many years.

Supplier Choice

Reputation

When you choose a supplier for stainless tanks, you want a company with a strong reputation. A trusted supplier shows long-term industry presence, high-quality products, and a focus on customer needs. For example, companies like Dixie Southern have operated since 1976 and hold respected certifications. You should look for similar qualities when buying steel tanks for your farm.

Key reputation factors to consider:

- Years of experience in manufacturing stainless tanks

- Certifications such as ASME Code Shop, which show compliance with safety and quality standards

- Positive customer feedback and long-term partnerships

- Reliable supply chain and efficient shipping

- Ability to deliver high-quality, competitively priced stainless tanks

Chenma stands out with over 200 professionals and a 20,000 m² facility. The company adapts stainless tanks to your needs and uses advanced machinery for precise fabrication. You benefit from a supplier that values quality and customer satisfaction.

Support

Support from your stainless tank supplier makes a big difference in your operation. You need technical help, clear communication, and strong after-sales service. Chenma offers full support, from design to installation and beyond. The team provides technical training, answers your questions, and helps you solve problems quickly.

When you evaluate suppliers, check their certifications and project experience. The table below shows important certifications and what they mean for you:

| Certification Type | Description | Importance for Agriculture Stainless Steel Tanks |

|---|---|---|

| ASME | Ensures tanks meet safety and quality codes for pressure and sanitary use | Protects your farm with safe, reliable stainless tanks |

| ISO 9001:2015 | Focuses on quality management and customer satisfaction | Gives you confidence in consistent, high-quality stainless tanks |

| AWS Welding Certification | Confirms welders meet strict standards for strength and durability | Ensures your stainless tanks last longer and resist leaks |

| Company-level Welding Certification | Requires regular audits and quality checks | Reinforces supplier reliability and excellence in stainless tank fabrication |

You get peace of mind when you choose a supplier with these credentials. Good support and strong certifications help you succeed when buying stainless tanks for agriculture.

Application Needs

Water Storage

You need reliable tanks for water storage on your farm. Stainless tanks give you a safe way to store water for irrigation, livestock, or drinking water. These tanks resist corrosion, even when you store water mixed with fertilizers. You can trust a stainless water storage tank to last for decades without rust or leaks.

Here are some reasons why stainless tanks work well for water storage:

- Stainless tanks keep your water clean. The smooth, non-porous surface prevents bacteria and dirt from sticking.

- You can store water for long periods without worrying about contamination. Stainless tanks do not react with water or fertilizers.

- These tanks handle harsh weather and tough farm conditions. You get strong structural integrity and fewer repairs.

- Stainless tanks come in many sizes. You can choose a tank that fits your daily water needs.

- International certifications, such as ISO 9001 and NSF/ANSI 61, show that these tanks meet strict safety and quality standards.

Tip: Use stainless tanks for both irrigation and drinking water. You protect your crops, animals, and family with safe, clean water.

Chemical Storage

You also need tanks for chemical storage on your farm. Stainless tanks offer the best protection for storing fertilizers, pesticides, and other agricultural chemicals. The right stainless steel tank grade, such as 304 or 316, gives you extra corrosion resistance for different chemicals.

- Stainless tanks prevent leaks and spills. Proper welding and thick walls keep your chemicals secure.

- You can store water mixed with chemicals for fertigation. Stainless tanks handle both the water and the chemicals without breaking down.

- Regular cleaning and inspection keep your tank in top shape. Stainless tanks are easy to clean, so you avoid cross-contamination.

- You can customize your tank with safety features, such as secure valves and venting systems. This helps prevent accidents and protects your farm.

Many farmers use stainless tanks for both storage and transport. You can mount these tanks on trucks or trailers for easy movement. Always match the tank size and grade to your chemical and storage needs.

Note: Stainless tanks give you peace of mind. You know your chemicals stay safe, and your storage meets all safety rules.

When you choose stainless steel tanks for agriculture, you protect your operation with durability, hygiene, and chemical compatibility. Always match tank features to your farm’s needs. Use this checklist before you decide:

- Check the stainless steel grade, such as 304 or 316.

- Review Safety Data Sheets for chemical compatibility.

- Select fittings that resist corrosion.

- Pick tank designs that help remove settled materials.

- Consider agitation options to keep contents mixed.

- Choose the right gasket and seal materials.

- Confirm compatibility with suppliers.

- Learn from past mistakes to avoid costly errors.

You get the best results when you work with certified, experienced suppliers like Chenma. For tailored solutions, consult experts who understand your agricultural needs.

FAQ

What grade of stainless steel should you choose for agricultural tanks?

You should choose 304 or 316 stainless steel. Grade 316 works best for storing chemicals or fertilizers because it resists corrosion from chlorides. Grade 304 suits water and mild liquids. Always match the grade to your storage needs for safety and long life.

How long do stainless steel tanks last on a farm?

You can expect stainless steel tanks to last over 30 years. Some tanks last up to 50 years with proper care. Their corrosion resistance and strong structure help them outlast plastic or mild steel tanks.

Are stainless steel tanks safe for storing drinking water?

Yes, stainless steel tanks are safe for drinking water. The smooth, non-porous surface prevents bacteria growth. Certifications like NSF/ANSI 61 and ISO 9001 show these tanks meet strict safety and hygiene standards for water storage.

Can you customize stainless steel tanks for your farm?

You can customize tank size, fittings, insulation, and safety features. Suppliers like Chenma offer custom engineering and turnkey solutions. You get tanks that fit your farm’s needs, from water storage to chemical handling.

What certifications should you look for in a stainless steel tank supplier?

Look for ISO9001 for quality, ISO14001 for environmental management, OHSAS18001 for worker safety, and EU CE for European standards. These certifications show the supplier meets strict rules for safety, quality, and environmental care.