You want your wine making vats to last for years, right? Regular cleaning and inspection keep your winery tanks in top shape. Good temperature and oxygen control help your wine age perfectly. When you choose tanks from Chenma, you get proven durability and quality. Chenma’s winery tanks meet strict quality standards and support long-term wine aging. Take care of your tanks and you protect your wine, your winery, and your investment.

Cleaning Wine Making Vats

Keeping your wine making vats clean is the first step to producing high-quality wine every time. If you skip proper cleaning, you risk contamination and spoilage. Let’s break down the best ways to keep your tanks spotless and ready for the next batch.

Cleaning Steps

You want your tanks to be as clean as possible before you start a new batch of wine. Here’s a step-by-step process that many professional wineries follow:

- Rinse the tank with cold or warm water (no warmer than 109°F). Use a high-pressure spray at an angle to knock off any leftover wine or debris.

- Apply an alkaline washing agent like sodium carbonate, sodium percarbonate, or caustic soda (1% solution for regular cleaning, up to 5% for tough stains). Let it soak for 10-15 minutes to dissolve sticky residues.

- Gently scrub the inside with a soft-bristle brush or pad. Avoid anything abrasive, especially with stainless steel tanks, so you don’t scratch the surface.

- Rinse thoroughly with cold water to remove all traces of the cleaning agent.

- Neutralize any alkaline residue by rinsing with a 1% citric acid solution.

- Sanitize the tank using a food-grade sanitizer like potassium metabisulfite, sodium metabisulfite, or a peroxyacetic acid-based product. Make sure you cover every surface.

- Do a final rinse with clean water if your sanitizer requires it. Some sanitizers don’t need rinsing, so check the label.

- Let the tank air dry completely. Check for any lingering odors. If you notice anything odd, repeat the cleaning process.

Tip: Always clean your tanks between every batch. This keeps your wine pure and your equipment in top shape.

Professional wineries clean their tanks and piping after every batch. During busy times like harvest, you should inspect and clean even more often. This routine helps you avoid contamination and keeps your stainless steel tanks looking and working like new.

Sanitizing Agents and Tools

You have a lot of choices when it comes to cleaning and sanitizing your tanks. Some work better for certain materials, but here’s what works best for stainless steel tanks:

- Alkaline cleaners (like caustic soda) break down organic residues from wine.

- Acid rinses (usually phosphoric acid blends) remove mineral deposits and neutralize leftover alkaline cleaner.

- Food-grade sanitizers (such as peroxyacetic acid or metabisulfite solutions) kill bacteria and other microbes.

- Mechanical tools make your job easier and more effective:

- High-pressure cleaners blast away stubborn residue.

- Steam cleaners sanitize without chemicals.

- Internal cleaning heads (rotating spray heads) reach every corner of the tank.

- Soft-bristle brushes help with tough spots, especially around valves and fittings.

Here’s a quick look at the most common agents and tools:

| Agent/Tool | Purpose | Best For |

|---|---|---|

| Caustic soda (alkaline) | Removes organic wine residue | Stainless steel tanks |

| Phosphoric acid (acid) | Removes mineral deposits, neutralizes | Stainless steel tanks |

| Peroxyacetic acid | Sanitizes, kills microbes | All tank types |

| High-pressure spray head | Removes debris, tartrate crystals | All tank interiors |

| Steam cleaner | Sanitizes without chemicals | Stainless steel tanks |

| Soft-bristle brush | Manual scrubbing, avoids scratches | Valves, fittings, corners |

Many modern stainless steel tanks, like those from Chenma, come with Clean-In-Place (CIP) systems. These systems use rotating spray heads to clean every inch of the tank automatically. You save time, use less water, and get consistent results every time. This makes easy maintenance a reality for your winery.

Chenma’s stainless steel tanks meet strict international standards for sanitation and quality. Certifications like ISO9001, ISO14001, OHSAS18001, and CE mean you get tanks that are safe, reliable, and easy to keep clean. You can trust that your wine will age in a hygienic environment, batch after batch.

Remember: Good cleaning and sanitation protect your wine, your tanks, and your reputation for quality.

Inspecting for Damage

Keeping your wine making vats in top shape means you need to check them often. Regular inspections help you catch problems early, so you can fix them before they get worse. Let’s look at what you should watch for and how you can keep your tanks working well for years.

Signs of Wear

You might wonder what to look for when you inspect your tanks. Industry experts point out several common signs of wear and tear:

- Seals and gaskets can break down over time. When this happens, leaks may start, and your wine could get contaminated.

- The tank body sometimes shows damage, corrosion, or wear. If you see these issues, the tank’s structure could be at risk.

- Damaged parts need quick repairs or replacement. Waiting too long can lead to spoiled wine.

- Pressure relief valves need regular checks. If they stop working, pressure can build up and cause problems.

- Always keep the pressure inside your tanks within safe limits. Too much pressure can damage the tank and hurt your wine.

If you spot any of these signs, take action right away. Quick fixes now can save you from bigger headaches later.

Preventive Care

You can do a lot to stop damage before it starts. Make a habit of checking your tanks after every use. Look closely at seals, gaskets, and valves. Clean and dry all parts to keep rust and corrosion away. Use only approved cleaning agents, since harsh chemicals can wear down the tank’s surface.

Set up a simple inspection checklist. Write down what you find each time. This record helps you spot patterns and plan repairs before small issues turn into big ones. When you care for your tanks, you protect your wine and your investment.

Tip: A little time spent on regular checks can add years to the life of your tanks and keep your wine safe.

Temperature Control for Wine Aging

Keeping your wine at the right temperature is one of the most important parts of the wine aging process. If you want your wine to develop great flavors and last for years, you need to pay close attention to temperature control in your tanks.

Ideal Temperature Range

You might wonder what temperature works best for wine aging. Experts agree that a cool, steady environment helps wine age slowly and safely. Here’s a quick look at what top winemakers and scientists recommend:

| Source | Temperature Range (°C) | Key Findings |

|---|---|---|

| Scientific article on cask aging | 10–14 | Constant temperature avoids evaporation loss and bacterial activity during 6–36 months of aging. |

| Nicolas Vivas (University of Bordeaux) | ~14–15 (below 18) | Cooler temps preserve freshness, fruit, and protect against spoilage. Higher temps cause off-flavors. |

| Karan Vasani (Sula Vineyards) | 14 (reduced from 17–18) | Cooler temps slow maturation, improve quality, and reduce spoilage. |

| Juan Pablo Murgia (Argentina) | 14–16 | Cooler temps favor fresher aromas and reduce heavy flavors. |

Most wineries aim for 55–60°F (about 13–16°C) for the wine aging process. This range keeps your wine safe from spoilage and helps it develop the best taste. If the temperature goes up and down, your wine can lose freshness or even spoil. Stable conditions are key for every batch you make.

Insulation and Monitoring

You want your tanks to keep a steady temperature, no matter what happens outside. Good insulation acts like a shield, stopping heat or cold from sneaking in. High-quality vapor barriers in the walls and ceilings of your storage area help reduce moisture loss and keep the temperature from changing too much. This protects your wine and makes your cooling system last longer.

Modern temperature control technology makes your job easier. Smart thermostats and hygrometers track the temperature and humidity inside your tanks. If something changes, you get an alert right away. You can fix problems before they hurt your wine. These tools help you avoid cork damage, oxidation, and spoilage. Some systems even combine cooling and humidification, creating a perfect space for aging wine.

Tip: Use temperature control systems and insulation together for the best results. This combo keeps your wine aging methods consistent and your tanks in top shape.

With the right setup, you give your wine the best chance to age gracefully. You also protect your tanks and your investment for years to come.

Oxygen Management in Winery Tanks

Keeping oxygen out of your tanks is one of the best ways to protect your wine. Too much oxygen can spoil the flavor and take away the freshness you work so hard to create. Let’s look at how you can keep your wine safe from oxidation and keep every batch tasting great.

Preventing Oxidation

You want your wine to keep its flavor and freshness. Oxidation can ruin both. Here are some of the most effective ways to stop oxygen from getting into your tanks:

- Use sulfur dioxide (SO2) at different stages. SO2 binds with oxygen and helps your wine keep its freshness and flavor.

- Try ultrasonic degassing. This new technology removes dissolved oxygen without chemicals. It helps your wine keep its color and flavor, and it works for wineries of any size.

- Handle your wine carefully. Move it gently and keep the headspace in your tanks as small as possible.

- Bottle your wine soon after it’s ready. This keeps it from sitting in tanks and picking up extra oxygen.

- Always measure dissolved oxygen and SO2 levels. This helps you control oxidation risk.

Tip: Ultrasonic degassing not only protects your wine’s flavor, but also appeals to customers who want fewer additives in their wine.

Inert Gas Flushing

Inert gas flushing is a simple but powerful way to keep oxygen away from your wine. You use gases like nitrogen, argon, or carbon dioxide to push out the oxygen in your tanks. This keeps your wine safe and helps it keep its flavor.

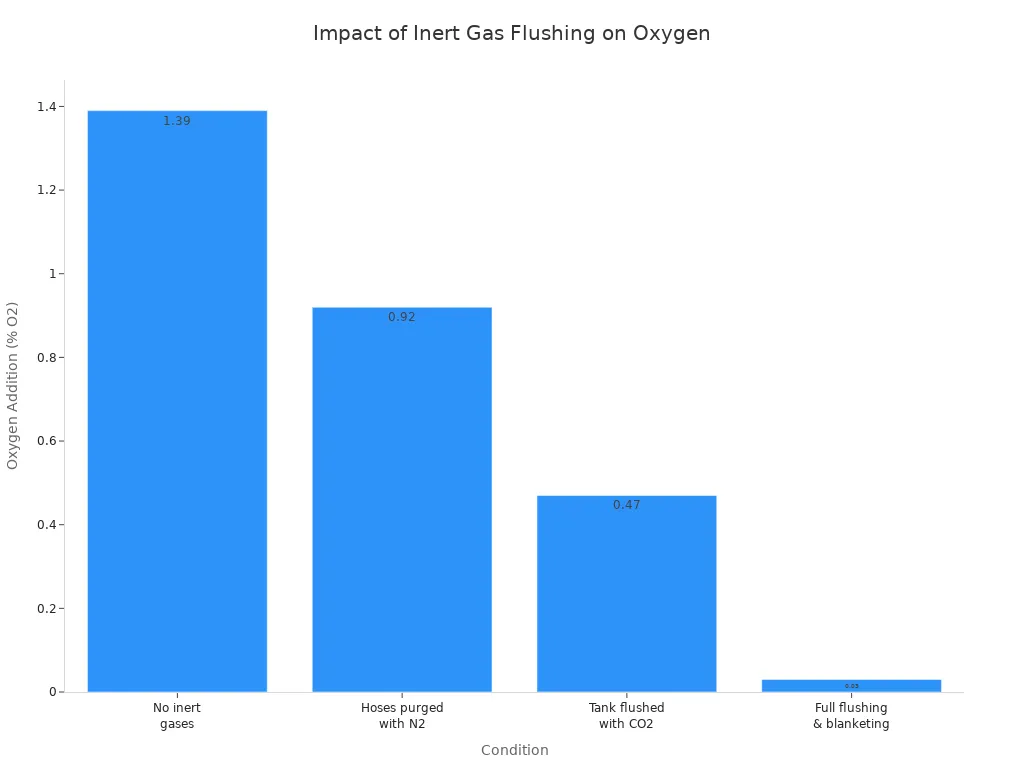

Here’s how different methods stack up:

| Condition | Oxygen Addition (% O2) |

|---|---|

| No inert gases | 1.39 |

| Hoses purged with nitrogen | 0.92 |

| Tank flushed with CO2 | 0.47 |

| Full flushing & blanketing | 0.03 |

When you flush your tanks and hoses with inert gas, you cut down oxygen levels fast. Full flushing and blanketing can almost remove oxygen completely. This means your wine keeps its freshness and flavor from the tank to the bottle. Remember, heavier gases like CO2 and argon work best for pushing out oxygen. Keep your wine cool during these steps for even better results.

Note: Always check your oxygen levels after flushing. Good control means better wine and longer-lasting tanks.

Storage Conditions for Optimal Wine Aging

Humidity Control

You want your wine to age perfectly, so you need to keep an eye on humidity. If the air gets too dry, corks shrink and let oxygen sneak in. This can spoil your wine and ruin its freshness. Too much humidity brings mold, which damages labels and corks. You should aim for a humidity level between 50% and 70%. This range keeps corks moist and seals tight, helping your wine keep its flavor and quality.

Here’s a quick look at how humidity affects wine storage:

| Humidity Level | Effect on Wine Storage | Recommended Actions |

|---|---|---|

| 50% – 70% | Keeps corks moist, prevents oxidation, preserves wine quality | Maintain this range for optimal wine aging |

| Below 50% | Corks dry out, oxygen exposure, spoilage risk | Use humidifiers, monitor with hygrometers |

| Above 70% | Mold growth on labels and corks, damage to wine and presentation | Use dehumidifiers, ensure proper ventilation |

You can use a hygrometer to check humidity. If your cellar feels dry, add a humidifier. If it feels damp, try a dehumidifier. Stable humidity helps you avoid sudden changes that can hurt your wine. Regular checks for mold or leaks keep your storage safe. Well-sealed doors and moisture-resistant floors also help you control humidity.

Tip: Wine fridges or cabinets with humidity control make it easy to keep your wine in the best condition.

Storage Environment

The place where you store your wine matters just as much as humidity. The environment shapes how your wine ages and develops flavor. If you use oak barrels, the wood lets in a little oxygen. This slow oxygen transfer changes the wine’s color and taste, adding complexity. Barrels also release special compounds that boost flavor and help aging wine last longer.

Some winemakers use wood chips and micro-oxygenation to mimic barrel aging. These methods can speed up the process, but they create different flavors and chemical profiles. The temperature, pH, and dissolved oxygen in your storage area all play a role in how your wine ages. You want a space that stays cool, dark, and well-ventilated. This helps your wine keep its freshness and develop the best flavor.

If you want optimal wine aging, focus on steady conditions. Avoid big swings in temperature or humidity. Make sure your tanks or barrels are clean and free from leaks. Good storage helps your wine reach its full potential and keeps every bottle tasting great.

Remember: The right storage environment protects your wine, boosts flavor, and supports aging wine for years.

Material-Specific Vat Care

Taking care of your wine making vats depends on what they’re made of. Each material—stainless steel, oak, or plastic—needs its own approach. Let’s break down how you can keep your winery tanks in top shape and get the most out of your investment.

Stainless Steel Vats

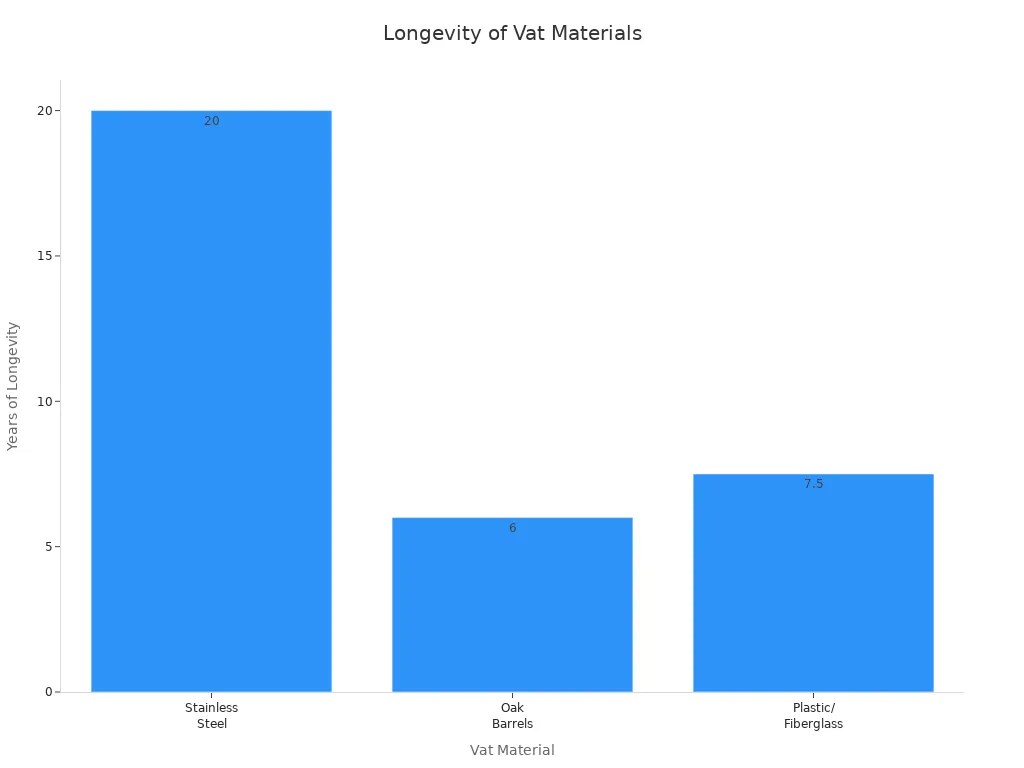

You’ll find that stainless steel tanks are the gold standard in many modern wineries. They last for decades and need very little maintenance. Here’s why so many winemakers choose them:

- Stainless steel vats resist corrosion and physical damage. Many last over 20 years, even with daily use.

- Cleaning is simple. You just need regular rinsing and occasional sanitizing.

- These tanks don’t add flavors to your wine, so you get a pure taste every time.

- You only need to do preventive checks, not constant repairs.

Chenma’s stainless steel tanks stand out for their quality and safety. They hold certifications like ISO9001, EU CE, ISO14001, and OHSAS18001. These show that your tanks meet strict international standards for durability and safe operation. Every tank goes through pressure testing and careful inspections before it leaves the factory.

When you pick Chenma winery tanks, you get long-term benefits and peace of mind. Your wine stays safe, and your equipment keeps working year after year.

Here’s a quick look at how different vat materials compare:

| Material | Durability & Longevity | Maintenance Requirements | Flavor Impact |

|---|---|---|---|

| Stainless Steel | Lasts 20+ years with minimal wear | Easy to clean, low maintenance | Neutral, no flavor added |

| Oak Barrels | Limited lifespan of 5-7 years | High maintenance, regular cleaning and conditioning | Adds flavors (vanilla, spice) |

| Plastic/Fiberglass | Lasts 5-10 years, prone to scratches | Moderate maintenance, risk of contamination | May leach flavors over time |

Oak Vats

Oak barrels and wood tanks give your wine unique flavors, but they need a lot of care. You must keep the wood wet to stop it from drying out and cracking. Fill the barrel with hot water to swell the staves and seal any leaks. Always check for cracks or leaks and use food-safe sealants like beeswax or mineral oil if needed. Store your barrels in a cool, shaded spot, away from sunlight and heat. When you’re not using them, fill them partway with water to keep the inside humid. Make sure the bung or cork fits tightly to keep air out.

Clean the outside of your wood tanks every month with a damp cloth. Skip harsh chemicals to protect the wood. Check for dryness or leaks every 6 to 12 months and apply food-grade sealant if needed.

Plastic Vats

Plastic vats are easy to use and clean, but they don’t last as long as stainless steel tanks. Most last 5 to 10 years. They’re less likely to add flavors to your wine than wood tanks, but scratches can trap bacteria. Always use soft brushes and gentle cleaners. Check for scratches and replace vats if you see deep marks. Store them in a cool, dry place to avoid warping or damage.

Plastic vats need less care than oak, but you should still keep them clean and check for signs of wear. They work well for short-term storage or small batches, but for longevity and quality, stainless steel tanks offer the best results for your winery.

Common Mistakes with Wine Making Vats

Errors to Avoid

You might think caring for your vats is simple, but small mistakes can lead to big problems for your wine. Here are some common errors you should watch out for:

- Skipping regular cleaning: If you leave residue or moisture inside your vats, bacteria can grow and spoil your wine.

- Ignoring volatile acidity (VA): High VA levels can ruin the taste and aroma. Many winemakers forget to measure VA at key stages, like after primary fermentation or malolactic fermentation.

- Poor storage conditions: If you let corks dry out or store wine in a place with low humidity, air can sneak in and cause oxidation. This makes your wine lose freshness.

- Not checking for cork taint: Smelling only the cork misses the real problem. Always smell the wine itself. Cork taint can come from barrels, corks, or even the winery environment.

- Using harsh cleaning tools: Scratches inside vats trap bacteria. Always use soft brushes and approved cleaners.

- Relying on quick fixes: Trying to blend or use reverse osmosis to fix faults often costs more and doesn’t solve the root issue.

Tip: Cleanliness and careful monitoring help you avoid costly mistakes and keep your wine tasting great.

Best Practices

You can avoid most problems by following a few smart habits. Here’s what top wineries recommend:

- Measure volatile acidity regularly. Use guides to pick the best times for VA checks, like after fermentation. Try using a cash still and titration for accurate results.

- Monitor VA at every stage. This helps you catch issues early and manage them before they affect your wine.

- Keep your barrels and vats clean. Review your barrel management often to stop spoilage and keep VA low.

- Store wine in a cool, humid place. This keeps corks moist and prevents oxidation.

- Refrigerate opened bottles to slow down oxidation and keep wine fresh longer.

- Smell the wine, not just the cork, to spot cork taint. If you find taint, discard the bottle and check your storage area for problems.

- Use your monitoring data to spot trends. If you see VA rising at certain stages, act fast to fix it.

- Remember, every wine has some VA. Keep it within safe limits to avoid faults and expensive fixes.

| Mistake | Impact on Wine | How to Prevent |

|---|---|---|

| High VA | Off-flavors, spoilage | Regular monitoring |

| Dry corks | Oxidation | Maintain humidity |

| Cork taint | Musty aroma, spoilage | Smell wine, clean area |

🍇 Stay proactive and your wine will reward you with great taste and quality.

Troubleshooting Winery Tanks

Early Warning Signs

You want to catch problems with your winery tanks before they get out of hand. Early warning signs help you spot trouble fast. Here are some things you should look for:

- Unusual smells, like rotten eggs or vinegar, can mean spoilage or unwanted bacteria.

- Cloudy wine or floating particles often point to contamination.

- Leaks around valves, seams, or gaskets show that your tanks may need repairs.

- Sticky residue or discoloration inside the tank can signal leftover wine or cleaning issues.

- Pressure changes or odd noises might mean a faulty valve or air getting in.

If you notice any of these signs, act quickly. Small problems can turn into big ones if you ignore them. Regular checks help you keep your tanks in top shape and your wine safe.

Tip: Keep a log of what you see during inspections. Patterns can help you find the cause of recurring issues.

Quick Fixes

When you spot a minor issue, you can often fix it right away and save your wine. Here are some quick fixes that work well for common problems in winery tanks:

- Add sulfites to bind acetaldehyde or control volatile acidity. This helps stop oxidation and spoilage fast.

- Rack the wine to remove any affected portions. This prevents further damage and keeps the rest of your batch safe.

- Use casein or PVPP treatments if you see light browning. These treatments clear up the wine and improve its look.

- Top up the tank regularly. This simple step reduces air exposure and stops oxidation. Many winemakers say this is one of the most effective ways to protect your wine.

- Check and repair any faulty equipment. Fixing leaks or broken valves keeps oxygen out and your tanks working well.

- Degas the wine with a vacuum pump if you notice unwanted bubbles or off-flavors. This removes dissolved gases that can harm wine quality.

| Quick Fix | What It Solves | How It Helps |

|---|---|---|

| Add sulfites | Oxidation, spoilage | Binds oxygen, preserves wine |

| Rack wine | Contamination, spoilage | Removes bad portions |

| Casein/PVPP | Browning, haze | Clears and brightens wine |

| Top up tank | Oxidation, surface films | Reduces air contact |

| Repair equipment | Leaks, oxygen ingress | Maintains tank integrity |

| Degas with vacuum | Unwanted gases, off-flavors | Improves taste and aroma |

You can solve many small problems with these steps. Quick action keeps your tanks running smoothly and your wine tasting great.

Maintenance Scheduling

Routine Planning

You want your wine making vats to last as long as possible. Setting up a routine plan makes this goal much easier. Start by creating a simple calendar for cleaning, inspections, and repairs. You can use a wall calendar, a digital reminder, or even a shared spreadsheet if you work with a team. Mark down when you last cleaned each vat, checked for leaks, or replaced seals. This way, you never miss an important step.

Try to schedule cleaning after every batch and a full inspection at least once a month. If you notice your vats get heavy use during harvest, add extra checks during that time. Routine planning helps you spot small problems before they turn into big ones. You avoid corrosion, residue buildup, and contamination. Your wine stays safe, and your equipment works better for longer.

Tip: Involve your team in the schedule. When everyone knows the plan, you catch issues faster and keep your winery running smoothly.

Record Keeping

Keeping good records is just as important as doing the work. Write down every cleaning, inspection, and repair. Note any leaks, odd smells, or changes in your vats. Over time, these records help you see patterns. You might notice a certain valve needs more attention or that a tank always shows residue in the same spot.

Detailed records let you catch wear, leaks, or contamination early. You can fix problems before they get expensive or disrupt your work. Good documentation also helps you plan future maintenance and train new staff on best practices. When you keep track of everything, you support stable operations and help your vats last longer. Consistent record keeping means your wine quality stays high, batch after batch.

Remember: A little time spent on records today saves you money and stress tomorrow.

When to Repair or Replace

Knowing when to fix your wine making tanks and when to get new ones can save you time and money. You want your equipment to last, but sometimes repairs just won’t cut it. Let’s look at how you can tell the difference.

Repair Indicators

You can often fix small problems and keep your tanks working well. Here are some signs that a repair makes sense:

- Minor leaks: If you see a drip around a valve or gasket, you can usually replace the seal or tighten the fitting.

- Surface scratches: Light scratches on stainless steel tanks do not affect performance. You can polish them out or clean them with a soft brush.

- Loose fittings: If a valve or clamp feels wobbly, you can tighten or replace it.

- Small dents: Dents that do not affect the tank’s shape or seal can be fixed with simple tools.

Tip: Always check your tanks after each cleaning. Early repairs stop bigger problems before they start.

Replacement Signs

Sometimes, repairs are not enough. You need to replace your tanks if you see these warning signs:

- Deep corrosion: If you spot rust or pitting inside the tank, it can spread fast. Corrosion weakens the metal and can ruin your wine.

- Cracks or splits: Any crack in the tank wall or weld means the tank is unsafe. Cracks can let in air or bacteria.

- Repeated leaks: If you fix a leak and it comes back, the tank may have hidden damage.

- Outdated safety standards: Tanks that do not meet current safety rules can put your wine and team at risk.

| Problem | Repair or Replace? | Why? |

|---|---|---|

| Minor leak | Repair | Easy fix, no risk to wine |

| Deep corrosion | Replace | Spreads quickly, weakens tank |

| Small dent | Repair | No effect on function |

| Crack in wall | Replace | Unsafe, risk of contamination |

Remember: If you are not sure, ask a professional. Keeping your tanks in top shape protects your wine and your business.

Taking care of your wine making vats pays off in the long run. Regular cleaning and oiling keep wood vats from drying out or cracking, which helps them last longer and makes cleaning easier. When you use high-quality tanks like Chenma’s, you get even more benefits:

- Stainless steel tanks protect wine flavor by stopping oxygen and keeping things clean.

- Strong seals and cooling systems help your wine age perfectly.

- Easy maintenance and after-sales support keep your equipment running smoothly.

Stick to a steady maintenance schedule. You’ll enjoy fresh, high-quality wine and reliable vats for years to come. 🍷

FAQ

How often should you clean your wine making vats?

You should clean your vats after every batch. During busy times, like harvest, inspect and clean them more often. Regular cleaning stops bacteria and keeps your wine tasting fresh.

What is the best temperature for wine aging in vats?

Aim for 55–60°F (13–16°C). This range helps wine age slowly and safely. Stable temperatures prevent spoilage and keep flavors pure. Use insulation and monitoring tools for best results.

Can you use any cleaning agent for stainless steel vats?

No, you should use approved alkaline cleaners like caustic soda and acid rinses such as phosphoric acid. Avoid harsh chemicals or abrasive tools. These can damage the tank and affect wine quality.

How do you know when to replace a wine making vat?

Replace your vat if you see deep corrosion, cracks, or repeated leaks. Outdated safety standards also mean it’s time for a new tank. Regular inspections help you spot these problems early.

Why choose Chenma stainless steel tanks for your winery?

Chenma tanks meet strict international standards like ISO9001 and CE. You get durable, easy-to-clean tanks with long lifespans. Their expert engineering and custom options support your winery’s unique needs.