The importance of choosing the right oil storage tank grows as global energy demands rise. By 2037, the oil storage tank service market is expected to reach $29.42 billion, driven by increasing consumption of fossil fuels, which exceeded 90 million barrels daily in 2020. Proper storage solutions will help manage this demand while ensuring safety and efficiency.

When selecting a stainless steel oil tank, you must consider several factors. The tank’s design, coating, and manufacturing process directly impact durability and environmental sustainability. Factory-made tanks offer better quality control and faster installation compared to field-built options. Safety features like corrosion resistance and certified coatings are essential to prevent leaks and contamination.

Chenma is one of the professional stainless steel wine tank manufacturers that can provide wineries with a variety of solutions. We also provide chemical mixing tank、cider tank, ect.

What is a Steel Oil Tank?

Overview of steel oil tanks

Steel oil tanks are specialized containers designed to store oil safely and efficiently. These tanks are constructed using durable steel materials, ensuring long-term reliability. They come in various designs, including vertical and horizontal configurations, to suit different installation needs. Steel oil storage tanks often feature heavy gauge shells and die-formed ends, which enhance their structural integrity. Many tanks include weather-resistant coatings to protect against harsh environmental conditions.

Technical specifications highlight their robust performance. For example:

| Characteristic | Description |

|---|---|

| Volume | Large volume tanks are common. |

| Placement | Centralized placement increases risk. |

| Inflammability | High risk of fire and explosions. |

| Corrosion Detection | External corrosion easier to detect. |

These features make steel oil tanks a preferred choice for storing heating oil, fuel oil, and other petroleum products.

Common applications of steel oil tanks

Steel oil tanks serve diverse industries due to their versatility and reliability. Some of the most common applications include:

| Application | Description |

|---|---|

| Oil & Gas | Requires large capacity tanks for storing significant amounts of oil. |

| Chemical Processing | Utilizes bunded steel oil tanks for safe storage of chemicals. |

| Manufacturing | Relies on robust tanks for efficient oil storage in production processes. |

| Power Generation | Needs secure storage solutions to minimize environmental risks. |

For residential use, home heating oil tanks provide a dependable solution for storing heating oil. In commercial and industrial settings, fuel oil tanks ensure uninterrupted operations by maintaining a steady supply of oil. These tanks also support heating oil delivery systems, making them essential for energy management.

Benefits of steel as a material for oil tanks

Steel offers unmatched durability and cost efficiency for oil storage tanks. Its resistance to corrosion ensures the tank’s longevity, especially when paired with effective corrosion management strategies. This reduces maintenance costs by up to 52% and minimizes downtime by 44.4%. Steel’s strength also enhances safety, preventing leaks and spills that could harm the environment.

Additional benefits include:

- Durability: Steel withstands harsh conditions, making it ideal for outdoor installations.

- Cost Efficiency: Repairs and maintenance are less frequent, lowering long-term expenses.

- Design Flexibility: Steel tanks can be customized to meet unique requirements, such as specific capacities or installation constraints.

Steel oil tanks combine reliability, safety, and efficiency, making them a top choice for storing heating oil, fuel oil, and other petroleum products.

Assessing Your Needs for a Steel Oil Tank

Determining the right capacity for your needs

Choosing the right oil tank size is one of the most important factors to consider when choosing an oil storage tank. The capacity requirements depend on your specific needs, whether for residential, commercial, or industrial use. Recent market analyses show that the demand for oil storage tanks is influenced by growing energy consumption and industrial activities. Smart tanks and sustainable designs are becoming popular, offering advanced monitoring systems and eco-friendly features.

When assessing capacity requirements, consider the following:

- Daily Consumption: Calculate the average oil usage to determine the appropriate tank size. For example, a home heating oil tank typically ranges from 275 to 500 gallons, while industrial tanks may exceed 10,000 gallons.

- Refill Frequency: Larger tanks reduce the need for frequent refills, saving time and costs.

- Space Availability: Ensure the tank fits within the designated area without compromising accessibility or safety.

Matching the tank’s capacity to your needs ensures efficient storage and minimizes operational disruptions.

Indoor vs. outdoor installation: What to consider

Deciding between indoor and outdoor installation involves evaluating site-specific conditions and safety requirements. Indoor tanks offer protection from weather elements, reducing the risk of corrosion. However, they require sufficient ventilation and space. Outdoor tanks, on the other hand, are ideal for properties with limited indoor space but must withstand environmental factors like temperature fluctuations and precipitation.

Key considerations for installation:

- Climate: Outdoor tanks in colder regions may need insulation to prevent oil from thickening.

- Accessibility: Indoor tanks should be placed in areas that allow easy access for maintenance and refilling.

- Safety Features: Outdoor tanks often include weather-resistant coatings and leak prevention systems to ensure durability.

For residential use, a home heating oil tank is often installed indoors to protect it from harsh weather. Commercial and industrial tanks, such as fuel oil tanks, are typically installed outdoors due to their larger size and advanced safety features.

Choosing a tank for residential, commercial, or industrial use

Choosing an oil tank depends on the application. Residential tanks prioritize safety and compliance with local regulations, while commercial and industrial tanks focus on capacity and durability. Market research highlights the differences between these tank types:

| Tank Type | Regulation Compliance | Safety Features |

|---|---|---|

| Residential | Exempt from federal regulation; local fire ordinances | Double-wall containment, leak detectors |

| Commercial | Must meet NFPA 30 and UL standards | Designed to withstand severe heat, prevent fires |

| Industrial | Subject to stringent safety standards | Double explosion-proof features for safety |

For residential use, a home heating oil tank ensures safe storage and efficient heating. Commercial tanks, such as fuel oil tanks, meet stringent standards to support business operations. Industrial tanks, often the largest segment, cater to high oil demand in manufacturing, mining, and power generation.

When choosing the right oil tank, consider application requirements, regulatory compliance, and site-specific conditions. These factors help you select a tank that meets your needs while ensuring safety and efficiency.

Types of Steel Oil Tanks

Single-wall steel oil tanks: Advantages and disadvantages

Single-wall steel oil tanks are a common choice for storing heating oil and fuel oil. These tanks consist of a single layer of steel, offering simplicity and cost-effectiveness. You might find them suitable for residential applications, such as a home heating oil tank, due to their lower upfront costs.

Advantages:

- Cost Savings: Single-wall tanks save over 15% on installation costs compared to double-wall tanks.

- Ease of Maintenance: With no external piping, these tanks reduce maintenance needs and lower insurance premiums.

- Proven Durability: Steel’s structural performance ensures reliability in various conditions.

Disadvantages:

- Higher Leak Risks: Studies show single-wall tanks have a higher leak rate, with 90% of leaks originating from devices other than the tank itself.

- Environmental Concerns: Leaks can lead to contamination, posing risks to soil and water.

| Tank Type | Leak Rate (%) | Source of Leak (%) |

|---|---|---|

| Single-wall tanks | Higher | 90% from devices other than UST |

Single-wall tanks may work well for smaller-scale applications, but you should weigh their environmental risks against their cost benefits.

Double-wall steel oil tanks: Advantages and disadvantages

Double-wall steel oil tanks offer enhanced safety features, making them ideal for storing heating oil and fuel oil in commercial and industrial settings. These tanks consist of an inner tank for oil storage and an outer tank that captures leaks, providing an added layer of protection.

Advantages:

Double-wall tanks excel in leak prevention and detection. Their design minimizes environmental risks by containing leaks within the outer tank. This feature reduces long-term operating costs and eliminates the need for external piping, which is a common source of leaks.

Disadvantages:

While double-wall tanks improve safety, they come with higher upfront costs. You may need to invest more initially, but the savings in maintenance and insurance premiums often offset this expense over time.

| Tank Type | Leak Rate (%) | Source of Leak (%) |

|---|---|---|

| Double-wall tanks | 2% | 9% from double-wall piping |

Double-wall heating oil tanks are a smart choice if you prioritize safety and environmental compliance. They are especially beneficial for large-scale applications where leak prevention is critical.

Horizontal vs. vertical steel oil tanks: Which is better?

Steel oil tanks come in two main configurations: horizontal and vertical. Choosing between these designs depends on your space, capacity needs, and installation preferences.

Horizontal Tanks:

Horizontal tanks are ideal for areas with limited vertical space. They provide stability and are easier to install in outdoor settings. These tanks often serve as fuel oil tanks for industrial applications, where large capacities are required.

Vertical Tanks:

Vertical tanks maximize storage capacity while occupying less floor space. They are commonly used as heating oil tanks in residential and commercial settings. Their design allows for efficient oil storage and delivery systems.

| Feature | Horizontal Tanks | Vertical Tanks |

|---|---|---|

| Space Efficiency | Requires more floor space | Occupies less floor space |

| Stability | Offers better stability | May require additional support |

| Common Use | Industrial fuel oil storage | Residential heating oil storage |

When deciding between horizontal and vertical tanks, consider your available space and the type of oil storage tank that best suits your needs. Horizontal tanks work well for industrial applications, while vertical tanks are better for residential and commercial use.

Features to Look for in a Steel Oil Tank

Durability and corrosion resistance

When selecting an oil storage tank, durability and corrosion resistance are critical features to consider. Steel tanks are known for their strength and ability to withstand harsh environments. They perform well under high pressure and resist damage from external elements better than plastic tanks. However, steel is prone to corrosion if not properly maintained.

There is a great correlation between the shedding of organic coating and the soaking in water, which further aggravates the corrosion of steel surfaces. Eliminating accumulated water and implementing effective prevention strategies significantly improve corrosion resistance.

Modern treatments, such as advanced coatings, have enhanced the corrosion resistance of steel tanks. Regular maintenance, including water removal, ensures a longer lifespan for your heating oil tank.

- Steel tanks are durable and suitable for outdoor installations.

- Proper maintenance prevents corrosion and extends tank life.

- Effective strategies reduce downtime and repair costs.

Safety features like leak prevention and fire resistance

Safety features to look for in an oil storage tank include leak prevention and fire resistance. These features protect your property and the environment from potential hazards. Double-wall tanks, for example, provide an extra layer of protection by containing leaks within the outer shell. Fire-resistant coatings and explosion-proof designs further enhance safety.

| Statistic | Value |

|---|---|

| Total Accidents Reviewed | 242 |

| Accidents in Petroleum Facilities | 74% |

| Accidents Due to Fire and Explosion | 85% |

| Accidents Caused by Lightning | 33% |

| Accidents Caused by Human Errors | 30% |

These statistics highlight the importance of choosing tanks with robust safety features. A well-designed heating oil tank minimizes risks and ensures compliance with safety standards.

Maintenance requirements and accessibility

Routine maintenance is essential for any oil storage tank. Neglecting inspections can lead to costly repairs and environmental damage. Tanks with accessible designs simplify maintenance tasks, such as cleaning and corrosion checks.

| Aspect | Details |

|---|---|

| Importance of Routine Checks | Tanks contain hazardous materials; neglecting integrity can lead to high costs for cleaning and waste disposal. |

| Risk Management | Tanks are complex; damage mechanisms include corrosion and differential settlement. |

| Inspection Optimization | Risk-directed inspection programs can minimize costs and enhance safety while meeting regulatory requirements. |

Acoustic emission and floor scanning techniques help identify potential issues early. By choosing a tank with easy access points, you can streamline inspections and ensure long-term reliability.

Environmental and Safety Considerations for Steel Oil Tanks

Compliance with regulations and standards

Adhering to oil tank regulations is essential for protecting tanks and fuel while ensuring environmental safety. Regular inspections help maintain the integrity of your oil storage tank and prevent leaks. Industry standards, such as the Spill Prevention, Control, and Countermeasure (SPCC) rule, require facilities to conduct integrity testing and implement spill prevention measures.

Owners or operators of aboveground oil storage tanks must comply with the SPCC rule, which mandates regular inspections and integrity testing to prevent spills and ensure environmental safety.

By following these regulations, you reduce risks and demonstrate your commitment to environmental and safety considerations. Compliance also ensures your tank meets legal requirements, avoiding penalties and operational disruptions.

Eco-friendly and sustainable tank options

Eco-friendly oil storage tanks offer sustainable solutions for reducing environmental impact. Recent studies highlight the success of natural ester liquid insulation in smaller and medium power transformers. Vegetable oil-loaded transformers have performed efficiently, meeting operational standards without issues.

- Over 200 transformers have utilized natural ester insulation successfully.

- A 240 kV and 300 MVA transformer with vegetable oil insulation operated flawlessly.

- Bio-lubricants outperform petroleum-based options in viscosity, lubricity, and biodegradability.

These advancements show the potential for sustainable oil tank designs. Choosing eco-friendly tanks helps you minimize your carbon footprint while maintaining efficiency.

Preventing leaks and spills: Best practices

Preventing leaks and spills is crucial for maintaining environmental and safety considerations. Facilities should develop a Spill Prevention, Control, and Countermeasure (SPCC) plan to document procedures and equipment for spill prevention. Essential strategies include:

- Install dikes and secondary containment systems to retain oil during a release.

- Conduct regular tank integrity and leak testing to ensure vessels remain in good condition.

- Implement pre-incident planning to review policies and diversion routes for effective incident management.

These practices protect tanks and fuel while reducing environmental risks. Regular maintenance and proactive measures ensure your oil storage tank operates safely and efficiently.

Cost Factors When Choosing the Right Oil Tank

Initial purchase price and what to expect

The initial cost of a steel oil tank depends on its size, type, and features. Residential tanks, such as home heating oil tanks, typically range from $500 to $2,000. Larger commercial or industrial tanks can cost upwards of $10,000. Double-wall tanks, which offer enhanced safety, are more expensive than single-wall options. However, their added protection against leaks often justifies the higher price.

When budgeting, consider the tank’s material and design. Tanks with advanced coatings or corrosion-resistant features may have a higher upfront cost but save money in the long run by reducing maintenance needs. Custom-designed tanks tailored to specific requirements also tend to cost more than standard models.

Installation costs and influencing factors

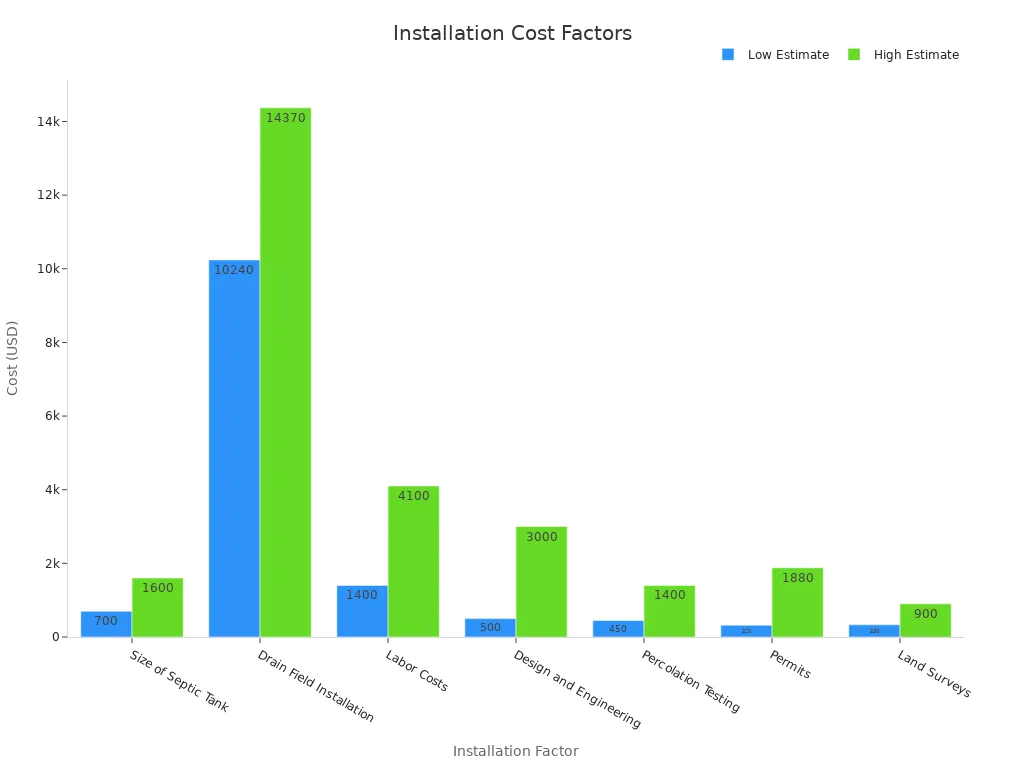

Oil tank installation costs vary based on several factors, including tank size, location, and labor requirements. On average, installation expenses range from $1,400 to $7,000. Labor accounts for 50% to 70% of the total cost, making it a significant factor. Additional costs may include permits, land surveys, and soil testing.

| Factor | Details | Cost Range |

|---|---|---|

| Size and Material | Standard anaerobic systems vs. alternative aerobic systems. | $2,000 – $20,000 |

| Labor and Installation | Includes equipment rental and labor costs. | $3,000 – $7,000 |

| Permit and Inspection Fees | Varies by location and system type. | $500 – $1,500 |

| Additional Costs | Site preparation, landscaping, and connections to the house. | $500 – $5,000 |

Outdoor installations may require weather-resistant coatings or insulation, increasing costs. Indoor installations, while protected from the elements, often involve additional ventilation or space considerations. Proper planning ensures you avoid unexpected expenses.

Long-term maintenance and repair expenses

Maintenance and repair costs for steel oil tanks depend on their design and usage. Regular inspections, cleaning, and corrosion prevention are essential to extend the tank’s lifespan. These tasks typically cost $200 to $500 annually. Tanks with advanced safety features, such as double walls, often require less frequent maintenance, reducing long-term expenses.

Repairs, such as fixing leaks or replacing damaged components, can cost between $500 and $3,000. Proactive measures, like installing leak detection systems, help minimize repair costs. Investing in a high-quality tank with durable materials reduces the likelihood of costly repairs over time.

Maintenance Tips for Your Steel Oil Tank

Regular inspections and cleaning routines

Regular tank inspections are essential for ensuring the safety and longevity of your steel oil tank. You should inspect your tank annually to detect potential issues early and prevent equipment failures. Cleaning routines also play a vital role in maintaining your tank’s performance. For example, water towers are inspected yearly for sanitation and structural integrity, and their coatings are checked every two to five years. Similarly, your oil tank should follow a cleaning and inspection schedule based on the manufacturer’s recommendations and your operating conditions.

By adhering to these schedules, you can avoid costly repairs and extend the life of your tank. Cleaning removes debris and contaminants that may lead to corrosion or blockages. Regular tank inspections also help you identify signs your oil tank needs replacement, such as rust, leaks, or unusual odors. Keeping your tank clean and well-maintained ensures it operates efficiently and safely.

Identifying and addressing wear or damage

Wear and damage are inevitable over time, but identifying them early can save you from expensive repairs. Analyzing oil samples is one way to detect wear particles and diagnose potential risks. This method provides insights into the condition of your tank and helps pinpoint the root causes of wear. For instance, wear debris analysis focuses on traces of steel iron, which can indicate corrosion or structural issues.

You should look for visible signs of damage, such as dents, cracks, or discoloration. Addressing these issues promptly prevents further deterioration. Proactive maintenance, like applying protective coatings or replacing worn components, ensures your tank remains in good condition. Regular monitoring and quick action can significantly reduce the risk of leaks or spills.

When to seek professional servicing

Some maintenance tasks require professional expertise. If you notice persistent issues, such as recurring leaks or severe corrosion, it’s time to call a professional. Experts in tank servicing and maintenance can perform advanced inspections, such as acoustic emission testing or floor scanning, to detect hidden problems. They also have the tools and knowledge to repair or replace damaged parts effectively.

Professional servicing is especially important for older tanks or those exposed to harsh environmental conditions. Regular servicing not only ensures compliance with safety standards but also extends the lifespan of your tank. By seeking professional help when needed, you can maintain the reliability and safety of your steel oil tank.

Making an Informed Decision on a Steel Oil Tank

Comparing options based on your specific needs

Choosing the right oil storage tank begins with understanding your specific requirements. Start by assessing the type of oil you plan to store, the volume needed, and the installation location. Residential tanks often prioritize compact designs and safety features, while industrial tanks focus on large capacities and durability.

Consider the environment where the tank will be installed. Outdoor tanks require weather-resistant coatings to withstand harsh conditions, while indoor tanks need proper ventilation and accessibility. For residential use, a steel oil tank with a capacity of 275 to 500 gallons may suffice. Industrial applications often demand tanks exceeding 10,000 gallons. Matching the tank’s features to your needs ensures efficient storage and compliance with oil tank regulations.

Balancing cost, quality, and features

Balancing cost, quality, and features is essential when choosing the right oil tank. Recent buyer surveys highlight key criteria for making informed decisions:

- Material compatibility ensures the tank safely stores the intended chemicals.

- Safety features like double walls and emergency relief valves prevent leaks and meet safety regulations.

- Budget considerations include tank size, material, and additional features that impact overall costs.

While single-wall tanks offer cost savings, double-wall tanks provide enhanced safety. Investing in a tank with advanced coatings or corrosion-resistant materials may increase upfront costs but reduce long-term maintenance expenses. Prioritize features that align with your needs without exceeding your budget.

Finding a reliable supplier or manufacturer

Selecting a trustworthy supplier ensures you receive a high-quality steel oil tank. Reliable manufacturers provide detailed verification data to support their product quality. Look for suppliers who offer:

- Measurement Systems Analysis (MSA) to confirm the accuracy of their quality checks.

- Dimensional Records that verify production samples meet specifications.

- Run-at-Rate Studies to ensure consistent manufacturing quality at required production rates.

- Raw Material Records documenting the composition and standards of materials used.

A reputable supplier also adheres to oil tank regulations and provides certifications for safety and environmental compliance. Companies like Shandong Chenma Machinery Co., Ltd. excel in customization and quality assurance, making them a dependable choice for your tank needs.

Why Choose Chenma for Your Steel Oil Tank Needs

Overview of Chenma’s expertise in tank manufacturing

Chenma stands out as a leader in steel tank manufacturing. With over 200 skilled professionals and a 20,000 m² production facility, the company delivers high-quality tanks tailored to diverse needs. Advanced machinery ensures precision in every design, from standard models to complex custom solutions.

Chenma’s focus on innovation drives its success. The company specializes in creating tanks for industries like oil storage, food processing, and energy. Each tank undergoes rigorous quality checks to meet modern safety and performance standards. This commitment to excellence makes Chenma a trusted name in the industry.

Tip: Choosing a manufacturer with advanced facilities and experienced engineers ensures your tank meets the highest standards of durability and safety.

Customization options for unique requirements

Chenma excels in offering tailored solutions for your specific needs. Whether you require insulation for temperature-sensitive materials or internal coils for heating and cooling, Chenma delivers. The engineering team, with over 15 years of experience, ensures these customizations are implemented effectively.

Additional features, such as extra ports for enhanced functionality, demonstrate Chenma’s ability to adapt to unique challenges. These options make their tanks suitable for a wide range of applications, from residential heating oil storage to industrial fuel systems.

By choosing Chenma, you gain access to tanks designed to fit your exact specifications. This flexibility ensures your tank performs optimally in any environment.

Certifications and quality assurance

Chenma prioritizes safety and quality in every product. The company holds multiple certifications, including ISO9001-2005 for quality management and ISO14001-2015 for environmental standards. These certifications reflect Chenma’s dedication to producing reliable and eco-friendly tanks.

| Certification | Focus Area |

|---|---|

| ISO9001-2005 | Quality management |

| ISO14001-2015 | Environmental management |

| OHSAS18001-2007 | Occupational health and safety |

| EU CE Certification | European safety and compliance |

These credentials ensure your tank meets global standards for safety, durability, and environmental responsibility. When you choose Chenma, you invest in a product backed by proven quality and trust.

Note: Certified tanks not only ensure compliance but also reduce risks, making them a smart choice for long-term use.

Choosing the right steel oil tank for 2025 is vital for ensuring safety, efficiency, and environmental protection. Understanding the buckling behavior of tanks under different loading conditions helps prevent failures that could lead to costly economic and environmental losses. You should prioritize tanks with durable designs, advanced safety features, and cost-effective maintenance options.

Evaluate your needs carefully, considering factors like tank type, installation location, and capacity. Consulting experts like Chenma ensures you make informed decisions that align with your requirements. Their expertise in customization and quality assurance guarantees reliable solutions for residential, commercial, and industrial applications.

FAQ

What is the lifespan of a steel oil tank?

The lifespan of a steel oil tank typically ranges from 15 to 30 years. Proper maintenance, such as regular inspections and corrosion prevention, can extend its durability. Tanks with advanced coatings or double-wall designs often last longer than standard models.

How do I know if my steel oil tank needs replacement?

Signs of replacement include visible rust, leaks, or unusual odors. Regular inspections can reveal structural damage or corrosion. If repairs become frequent or costly, replacing the tank ensures safety and efficiency.

Can I install a steel oil tank myself?

Professional installation is recommended for safety and compliance with regulations. Experts ensure proper setup, ventilation, and leak prevention. DIY installation risks improper handling, which may lead to environmental hazards or void warranties.

Are steel oil tanks environmentally friendly?

Steel oil tanks with eco-friendly coatings and leak prevention systems minimize environmental impact. Double-wall designs and compliance with SPCC regulations further enhance sustainability by reducing the risk of spills and contamination.

How often should I inspect my steel oil tank?

Annual inspections are essential to detect wear, corrosion, or leaks. For tanks in harsh environments, semi-annual checks may be necessary. Regular maintenance ensures safety, extends lifespan, and prevents costly repairs.