Stainless steel tanks play a key role in making food processing safer and more efficient. You see these tanks everywhere in the food and beverage industry because they keep products free from bacteria and contamination. At Chenma, experts design tanks stainless that meet strict hygiene standards and last for years. You benefit from easy cleaning, strong corrosion resistance, and full customization for your beverage or food and beverage industry needs. Tanks stainless also outperform other materials with their non-reactive surfaces, which support smooth, reliable operations every day.

Chenma is one of the professional stainless steel wine tank manufacturers that can provide wineries with a variety of solutions. We also provide chemical mixing tank、cider tank, ect.

Food Safety Benefits

Non-Reactive Surfaces

You want your food to stay pure and safe during processing. Stainless steel tanks provide a non-reactive surface, which means they do not interact with the liquids or ingredients inside. This feature keeps flavors unchanged and prevents unwanted chemical reactions. Stainless steel processing tanks do not absorb odors or colors, so every batch remains consistent. You can trust these tanks to handle a wide range of products, from dairy to juice, without risk of contamination. This makes stainless steel tanks a hygienic option for any food or beverage operation.

Easy Cleaning

Cleaning is one of the most important steps in food processing. Stainless steel processing tanks have smooth, non-porous surfaces that make cleaning simple and effective. You can remove residues and bacteria quickly, which helps you maintain a safe environment. Studies show that enzymatic cleaning agents work especially well on stainless steel, removing up to 99% of harmful biofilms like Listeria monocytogenes. This high level of cleanliness supports your efforts to prevent cross-contamination. You save time and resources because stainless steel tanks resist stains and buildup, making daily sanitation routines easier.

Tip: Regular cleaning with the right agents keeps your stainless steel processing tanks in top condition and ensures the highest food safety standards.

Bacterial Control

Bacteria can cause serious problems in food production. Stainless steel tanks help you control bacteria by supporting thorough cleaning and disinfection. The durable surface stands up to frequent washing, so you can sanitize tanks as often as needed. This reduces the risk of pathogens spreading between batches. Stainless steel processing tanks also support compliance with strict food safety rules. Chenma manufactures tanks that meet international standards, including ISO9001, CE, ISO14001, and OHSAS18001. These certifications prove that your tanks come from a process focused on safety, quality, and hygiene.

| Certification/Standard | Relevance to Food Safety and Compliance |

|---|---|

| ISO9001 Quality Management System | Ensures consistent quality management processes that maintain hygienic and safe manufacturing practices, critical for food safety. |

| EU CE Certification | Guarantees compliance with European safety, health, and environmental standards, ensuring tanks meet stringent food safety requirements. |

| ISO14001 Environmental Management | Demonstrates environmentally responsible manufacturing, supporting safe and sustainable production. |

| OHSAS18001 Occupational Health and Safety | Prioritizes worker safety during production, indirectly supporting safe manufacturing environments. |

You can rely on stainless steel tanks from Chenma to help you meet the highest standards for food safety. Their design and certifications make them the best choice for keeping your products safe and your operations compliant.

Efficient Liquid Processing

Streamlined Operations

You want your production line to run smoothly every day. Stainless steel processing tanks help you achieve efficient liquid processing by supporting fast and reliable workflows. These tanks handle a wide range of liquids, from juices to alcohol, without causing delays or contamination. The smooth, non-porous surfaces allow liquids to flow easily, which improves mixing efficiency and reduces the risk of product loss.

When you use stainless steel processing tanks, you notice that your team spends less time on cleaning and more time on actual production. The tanks’ design supports automated systems, so you can control temperature, pressure, and mixing with precision. This level of control leads to consistent results and higher product quality.

Chenma offers turnkey solutions that cover every step of your project. You get help with process design, equipment manufacturing, installation, commissioning, and technical training. This means you do not have to coordinate with multiple suppliers. Instead, you receive a complete system that works together from day one. Your operations become more efficient because every part of the process fits perfectly.

Note: With Chenma’s technical support, you can quickly solve any issues that arise. This keeps your production line moving and helps you avoid costly delays.

Reduced Downtime

Downtime can hurt your business. Every minute your equipment stops, you lose valuable production time. Stainless steel processing tanks from Chenma help you minimize downtime and keep your operations running.

You benefit from advanced features like predictive maintenance systems. These systems monitor your tanks and alert you before problems occur. Studies show that predictive maintenance can reduce unplanned downtime by up to 50%. This means you spend less time fixing issues and more time producing high-quality products.

Chenma customizes stainless steel processing tanks to fit your needs. For example, you can choose tanks with advanced cooling systems for precise temperature control. This customization improves operational reliability and supports efficient liquid processing. You also gain from Chenma’s international certifications, such as ISO9001, ISO14001, OHSAS18001, and EU CE Certification. These certifications prove that your equipment meets strict quality and safety standards, which lowers the risk of unexpected breakdowns.

- Chenma’s approach to efficient liquid processing includes:

- Turnkey solutions for seamless integration.

- Custom equipment for better mixing efficiency.

- Predictive maintenance to reduce downtime.

- Ongoing technical support for fast problem-solving.

When you choose stainless steel processing tanks from Chenma, you invest in equipment that keeps your production line moving. You save time, reduce costs, and deliver consistent results to your customers.

Durability and Longevity

Corrosion Resistance

You want tanks that last for years, even in tough environments. Stainless steel tanks give you this advantage because they resist corrosion better than most other materials. The high chromium content in stainless steel forms a protective layer on the surface. This layer shields your tank from saltwater, acids, and harsh cleaning chemicals. As a result, your tanks stay strong and safe for a long time.

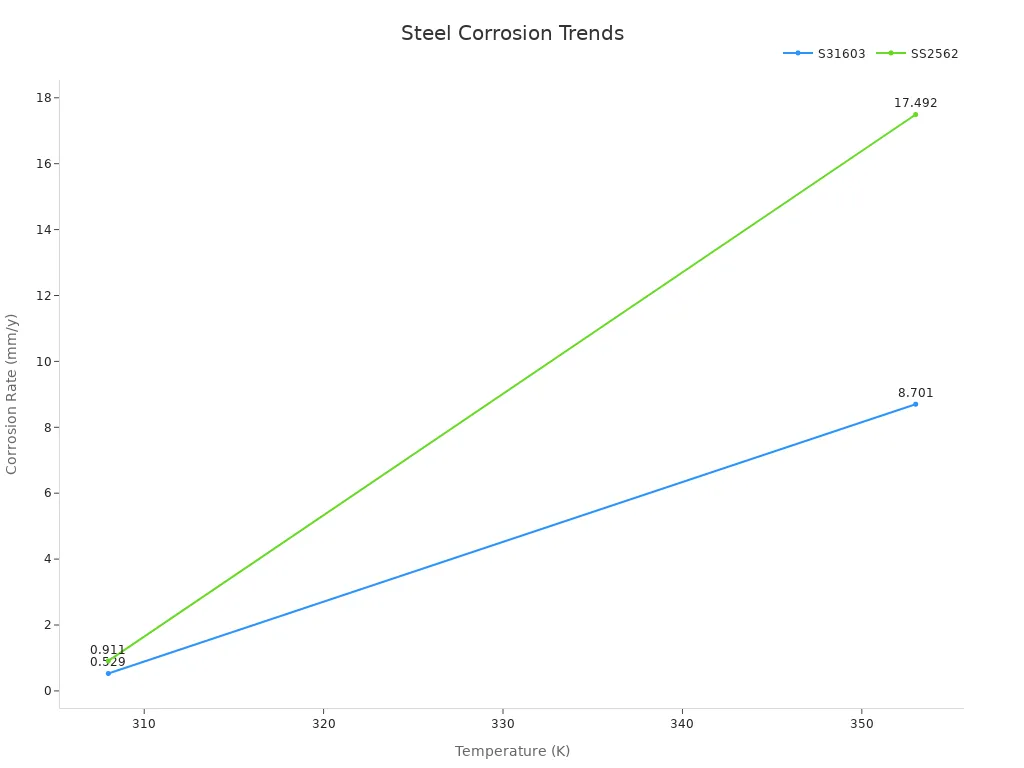

In industries like oil and gas, stainless steel tanks often last for decades. They do not crack or leak easily because the material resists pitting and stress corrosion. Scientific studies show that certain stainless steel alloys, like S31603, have very low corrosion rates even at high temperatures. This means your tanks can handle aggressive liquids without breaking down.

| Stainless Steel Alloy | Temperature (K) | Corrosion Rate (mm/y) | Morphological Observations |

|---|---|---|---|

| S31603 | 308 | 0.529 | Numerous shallow pits, minimal microstructural deterioration |

| S31603 | 353 | 8.701 | Protective oxide formed but unstable; minimal deterioration compared to SS2562 |

| SS2562 | 308 | 0.911 | Metastable pitting at 0.02 V; larger micro-pits visible |

| SS2562 | 353 | 17.492 | Advanced morphological deterioration; grain boundaries more visible |

Low Maintenance

You save time and money when your tanks need less care. Stainless steel tanks from Chenma require very little maintenance because of their strong construction and smart design. Chenma uses high-grade 304 and 316 stainless steel, which gives your tanks extra strength and corrosion resistance. Features like domed tops and conical bottoms help prevent sediment buildup, so you clean your tanks less often.

Chenma’s engineers reinforce tank walls and add venting systems for safety and durability. Advanced agitation systems, such as high-shear mixers, reduce stress on the tank and improve mixing. Every tank goes through strict quality checks, including pressure testing and inspections. These steps make sure your tank meets international standards and lasts longer.

Tip: Custom options like internal coatings or heating jackets help your tank fit your exact needs, making it even more durable and easy to maintain.

You get a tank that works hard for you, year after year, with fewer repairs and less downtime.

Versatility in Food Processing

Multiple Applications

You can use stainless steel tanks in almost every area of food and beverage production. These tanks work well for dairy, juice, beer, and wine. In dairy processing, you need tanks that keep milk safe and fresh during storage and mixing. Stainless steel tanks help you control temperature and prevent spoilage. When you make juice, you want to keep flavors pure and avoid contamination. Stainless steel tanks do not react with acids in fruit juice, so your product stays high quality.

If you work in beer or wine production, you need tanks that support fermentation and storage. Stainless steel tanks give you precise control over temperature and mixing. This helps you create consistent batches of beer and wine. Many companies use these tanks for kombucha, pickles, and sauces as well. The tanks’ smooth surfaces make cleaning easy, which is important for any food or beverage process.

Stainless steel tanks use advanced mixing technology and control systems. You can add heating or cooling jackets to meet your process needs. This flexibility shows why stainless steel tanks are a top choice for food processing.

Custom Solutions

You may have unique needs for your food or beverage business. Chenma can customize stainless steel tanks for you. You can choose the size, shape, and features that fit your process. Chenma offers tanks from 100L to 50,000L, so you can find the right storage solution for small or large operations. Their engineers use high-quality 304 or 316 stainless steel, which keeps your food safe and your tanks durable.

Chenma uses advanced welding and polishing methods to make sure your tanks last a long time. You get options like mirror-polished finishes, special mixing systems, and temperature control. Chenma’s tanks come with a 3-year warranty on core parts. You also get strong customer support, including installation and maintenance. Their ISO 9001 and EU CE certifications show that you can trust their quality and safety.

- You can rely on Chenma for:

- Custom tank sizes and shapes

- Advanced mixing and temperature control

- Reliable storage for beer, wine, juice, and more

- Full support from design to after-sales service

Stainless steel tanks from Chenma help you meet the demands of any food or beverage process. You get safe storage, easy cleaning, and the flexibility to grow your business.

Stainless Steel Processing Tanks vs. Other Materials

Plastic and Glass Issues

When you choose a tank for food processing, you want to keep your products safe and tasting fresh. Plastic tanks may seem convenient because they are lightweight, but they can cause problems. Even BPA-free plastics can release chemicals when exposed to heat. This can affect both the taste and safety of your food or drink. You might notice a strange flavor, especially if you use the tank for hot liquids. Over time, plastic tanks can wear down and become less sturdy.

Glass tanks offer a non-reactive surface, so they do not change the taste of your product. You can trust glass to keep your food safe from harmful chemicals. However, glass tanks break easily and can be hard to handle in large-scale operations. They also do not provide the same level of durability as stainless steel.

Here is a quick comparison to help you see the differences:

| Attribute | Stainless Steel | Plastic (BPA- and BPS-free SAN) | Glass |

|---|---|---|---|

| Durability | Highly durable, resistant to wear | Less sturdy over time | Durable but breakable |

| Safety | Non-reactive, no harmful chemical leaching | BPA- and BPS-free, but concerns remain especially with heat exposure | Non-reactive, free from harmful chemicals |

| Taste | Preserves taste well, non-reactive | Potential taste concerns, especially when heated | Preserves taste well, non-reactive |

Note: Stainless steel and glass both protect taste and safety, but only stainless steel gives you the strength and reliability needed for busy food processing environments.

Metal Alternatives

You might also consider other metals, such as aluminum, for your tanks. Aluminum tanks cost less, but they do not resist corrosion as well as stainless steel. Over time, aluminum can react with acidic foods or cleaning chemicals. This reaction can lead to leaching, which may affect both the taste and safety of your product. Stainless steel heating elements are preferred because they do not corrode or leach harmful substances.

You get several advantages when you choose stainless steel:

- Stainless steel resists corrosion and stands up to harsh cleaning agents.

- You avoid harmful chemical leaching, even with hot liquids.

- Cleaning is easier, which reduces the risk of bacteria.

- Stainless steel tanks meet strict certifications, such as FDA, SCA, and Prop 65.

You want a tank that keeps your food safe, preserves taste, and lasts for years. Stainless steel tanks deliver on all three, making them the best choice for modern food processing.

Regulatory Compliance

Industry Standards

You need tanks that meet strict food safety rules. Stainless steel tanks help you follow both FDA and international standards. The FDA sets rules under Title 21, parts 176-177 of the Code of Federal Regulations. These rules make sure tanks are safe for storing food and drinks. Stainless steel tanks meet these requirements because they do not react with food or drinks. Food-grade 304 stainless steel is a top choice. It is safe for direct contact with food and is easy to clean. This makes it perfect for food processing, storage, and preparation.

Many tanks also use special linings, such as vinyl ester or epoxy vinyl ester coatings. These coatings add extra protection. They resist chemicals and abrasion, which helps keep your food safe. You can trust that stainless steel tanks with these features will help you meet both FDA and international food safety standards.

Tip: Always check that your tanks use food-grade stainless steel and proper linings for the best safety and compliance.

Certifications

You want proof that your tanks meet the highest standards. Chenma provides this proof through strong certifications and quality checks. The company holds several important certifications:

| Certification Type | Chenma Stainless Steel Tank |

|---|---|

| ISO9001-2005 | Yes |

| ISO14001-2015 | Yes |

| OHSAS18001-2007 | Yes |

| EU CE Certification | Yes |

These certifications show that Chenma follows international rules for quality, safety, and the environment. The company uses strict quality control at every step, from design to installation. You also get support after your purchase, including 24-hour online help and warranties. This means your tanks stay reliable and safe for years. When you choose Chenma, you avoid legal or operational problems because your tanks always meet local and international standards.

Choosing Tanks Stainless

Key Features

When you choose a tank for food processing, you want features that keep your products safe and your operations smooth. Look for tanks with smooth, non-porous surfaces. These surfaces make cleaning easier and help prevent bacteria from sticking. Tanks with rounded corners and welded seams also reduce places where residue can build up. You should check for strong lids and secure fittings. These parts keep your liquids safe from outside contamination.

A well-designed stainless steel processing tank should support easy cleaning and resist corrosion. You want tanks that work with automated cleaning systems. This saves you time and helps you meet strict hygiene standards. Make sure your tank can handle the temperature and pressure of your process. Tanks with built-in temperature control or mixing systems give you more control over your product quality.

Tip: Always ask your supplier about cleaning protocols and compatible cleaning agents. Proper cleaning keeps your tank safe and extends its life.

Grades and Materials

Not all stainless steel grades work the same way in food processing. You should know the differences before you choose. Grade 304 stainless steel is a popular choice. It resists corrosion well and keeps its surface smooth. Grade 316 offers even better resistance, especially when you process salty or acidic foods. Grade 430 is less expensive, but it is more likely to develop pitting corrosion, especially if you use cleaning agents with chloride.

Here is a quick comparison of common grades:

| Stainless Steel Grade | Corrosion Resistance | Best Use Case |

|---|---|---|

| 304 | High | Most food and beverage products |

| 316 | Very High | Salty, acidic, or harsh environments |

| 430 | Moderate | Dry foods, low-risk liquids |

Studies show that 304 and 316 grades release very low amounts of metal, which keeps your food safe. Grade 430 can release more metal and is more likely to pit if you do not follow proper cleaning steps. Always choose a grade that matches your process and cleaning needs.

When you evaluate suppliers like Chenma, check for certifications such as ISO9001 and CE. Ask about their quality control and custom options. A good supplier will help you pick the right tank features and materials for your business.

Maintenance Best Practices

Cleaning Methods

You want your stainless steel tanks to stay clean and safe for every batch. Start by rinsing the tank with warm water right after use. This step removes most of the leftover product. Next, use a food-safe cleaning agent. Make sure you reach all surfaces, especially the bottom of the tank. Studies show that the bottom is often the hardest area to clean. Researchers have used special tools like fluorescent stains and UV light to check for hidden bacteria. They also use swabbing and microbial culturing to measure how well cleaning works. These tests prove that careful cleaning removes almost all harmful germs.

For best results, use a spray ball or automated cleaning system. These tools help you reach every part of the tank. Computational fluid dynamics (CFD) models show that strong water flow and high wall shear help remove sticky residues. If you clean tanks often and use the right methods, you keep your storage area safe and hygienic.

Tip: Always check for spots that are hard to reach. Use a flashlight or UV light to inspect the tank after cleaning.

Extending Lifespan

You can make your stainless steel tanks last for many years with a few simple steps. Always dry the tank after cleaning. This prevents water spots and rust. Inspect the tank regularly for scratches or dents. Even small marks can trap bacteria and make cleaning harder. If you find damage, repair it right away.

Store your tanks in a dry, clean place. Good storage keeps your tanks in top shape and ready for safe storage of food and drinks. Avoid using harsh chemicals or steel wool, as these can scratch the surface. Use only soft brushes and approved cleaning agents. Schedule regular maintenance checks to catch problems early.

| Maintenance Task | Frequency | Benefit |

|---|---|---|

| Rinse after each use | Every use | Removes residue, prevents buildup |

| Deep clean with agent | Weekly | Keeps tank hygienic |

| Inspect for damage | Monthly | Prevents long-term issues |

| Dry and store properly | Every use | Extends tank lifespan |

By following these steps, you protect your investment and ensure your tanks provide safe storage for every batch.

Cost and Value

Investment Return

When you choose a stainless steel tank, you make a smart investment for your business. The upfront cost may seem higher than other options, but you gain much more over time. Stainless steel tanks last over 50 years, while enamel-coated tanks often last only about 20 years. You do not need to replace them as often, which saves you money in the long run. The strong, corrosion-resistant surface stands up to daily use and harsh cleaning. You also get better energy efficiency because stainless steel tanks keep heat inside, reducing energy loss.

Here is a quick comparison of common tank materials:

| Material | Advantages | Drawbacks |

|---|---|---|

| Stainless Steel | Long lifespan (>50 years), corrosion-resistant, durable, energy efficient, pressure resistant | Higher initial cost |

| Enamel-Coated | Cost-effective, good corrosion resistance | Shorter lifespan (~20 years), prone to cracking |

| Plastic/Composite | Lightweight, affordable | Susceptible to UV damage, lower heat retention |

| Copper | Excellent thermal conductivity | Expensive, prone to scaling |

You see that stainless steel tanks cost more at first, but their durability and low maintenance needs make them the best value over time.

Long-Term Savings

Stainless steel tanks help you save money and protect the environment. You use less energy because these tanks have strong insulation and efficient designs. You spend less on repairs and replacements, since stainless steel resists corrosion and damage. Many manufacturers recycle stainless steel, including important metals like chromium and nickel. This reduces waste and supports green practices.

- Stainless steel tanks are highly recyclable, which lowers environmental impact.

- Energy-efficient manufacturing and tank design cut down on your energy bills.

- The smooth, hygienic surface keeps your food safe and reduces cleaning costs.

- Smart monitoring systems let you track tank performance and plan maintenance, so you avoid costly downtime.

- Using recycled materials and recycling old tanks supports global sustainability goals.

By choosing stainless steel tanks, you invest in equipment that pays you back year after year. You lower your operating costs, meet strict food safety rules, and help the planet at the same time.

You make your food processing safer and easier when you choose stainless steel tanks. Tanks stainless help you keep your products clean and free from bacteria. Chenma gives you quality, custom options, and strong compliance with safety rules. Stainless steel tanks last for years and work well in many food industries. If you want to upgrade, look for tanks stainless that fit your needs.

Next step: Contact Chenma for advice on the best stainless steel tanks for your process.

FAQ

How do stainless steel tanks help you keep food safe?

Stainless steel tanks have non-reactive, smooth surfaces. You clean them easily and remove bacteria. These tanks do not absorb flavors or odors. You meet strict food safety standards with tanks from Chenma, which hold ISO9001 and CE certifications.

Can you customize stainless steel tanks for your process?

Yes, you can. Chenma offers tanks in many sizes and shapes. You choose features like mixing systems, temperature control, and special finishes. Engineers design tanks to fit your unique needs in dairy, juice, alcohol, or other food sectors.

How often should you clean your stainless steel tank?

You should rinse your tank after every use. Deep clean it weekly with a food-safe agent. Regular cleaning prevents residue buildup and keeps your tank hygienic. Automated cleaning systems help you reach all surfaces and save time.

What certifications should you look for in a stainless steel tank?

Look for tanks with ISO9001, ISO14001, OHSAS18001, and EU CE certifications.

These certifications show your tank meets international standards for quality, safety, and environmental responsibility. Chenma provides tanks with all these certifications.