Steel oil tanks play a crucial role in storing oil and other liquids safely and efficiently. Their durability and adaptability make them an essential choice for industrial, residential, and commercial applications. For instance, the average lifespan of these tanks is approximately 20 years, though some can last significantly longer depending on environmental factors. The demand for these tanks continues to grow, with the storage tank market expected to reach $41.8 billion by 2031. Whether used aboveground or underground, a stainless steel oil tank offers unmatched reliability for modern storage needs.

Chenma is one of the professional stainless steel wine tank manufacturers that can provide wineries with a variety of solutions. We also provide chemical mixing tank、cider tank, ect.

What is a Steel Oil Tank?

Definition and purpose

A steel oil tank is a specialized container designed to store liquids like crude oil, refined oil, or other organic and nonorganic substances. These tanks are essential for industries that require safe and efficient storage solutions. They serve as a reliable way to manage large quantities of liquids or gases for later use or distribution.

| Definition | Purpose |

|---|---|

| A storage tank is a large container designed to hold and store liquids, compressed gases, or mediums for the short- or long-term storage of heat or cold. | Storage tanks provide a dependable means to store and manage substantial quantities of liquids or gases. |

| Oil storage tanks are used to store crude oil as well as processed or refined oil. | They are necessary to hold crude oil after separation and before refining. |

| Storage tanks contain organic liquids, nonorganic liquids, and vapors and can be found in many industries. | Most tanks are built to the American Petroleum Institute (API) 650 specification, ensuring safety and reliability. |

Steel oil tanks are widely used in industries like energy, agriculture, and transportation. Their robust design ensures they can handle the demands of storing oil and other liquids under various conditions.

Key features and characteristics

Steel oil tanks stand out due to their durability and versatility. They are built to last and provide reliable storage solutions across different applications. Here are some key features that make them a preferred choice:

- Longevity: Steel tanks resist UV degradation and structural failures, offering a longer lifespan compared to plastic alternatives.

- Security: Their sturdy construction makes them more secure against theft.

- Cost-effectiveness: Steel tanks provide excellent long-term value. You can relocate or resell them, making them a flexible investment.

- Minimal site preparation: Unlike plastic tanks, steel tanks require less preparation, as they do not need perfectly level concrete bases.

- Flexibility: Steel tanks adapt to various industries and applications, making them a versatile storage option.

The design of these tanks also incorporates critical principles to ensure safety and efficiency. For example:

- Material Selection: Manufacturers use carbon steel or stainless steel to ensure compatibility with the stored substances.

- Structural Integrity: Tanks are built to withstand environmental and operational stresses.

- Sealing and Leak Prevention: High-quality seals and regular maintenance prevent leaks.

- Design Considerations: Factors like capacity, foundation stability, and ventilation are carefully planned.

- Compliance with Standards: Tanks adhere to guidelines from organizations like the American Petroleum Institute (API) to ensure reliability.

These features make steel oil tanks a dependable choice for storing oil and other liquids in various industries.

Common Applications of Steel Oil Tanks

Steel oil tanks are used across various sectors due to their durability, versatility, and ability to store oil and other liquids safely. Their applications span industrial, residential, and commercial settings, making them an essential part of modern infrastructure.

Industrial uses (e.g., factories, power plants)

In industrial settings, steel oil tanks play a vital role in storing oil and other fuels required for large-scale operations. Factories often rely on these tanks to store diesel, kerosene, or waste oil for powering machinery and backup generators. Power plants use them to store fuel for energy production, ensuring uninterrupted operations during peak demand.

Steel oil storage tanks are designed to handle the rigorous demands of industrial environments. Their robust construction resists wear and tear, even under extreme conditions. Bunded oil tanks, which feature a secondary containment layer, provide an added layer of safety by preventing leaks and spills. This feature is especially important in industries where environmental compliance is critical.

Residential uses (e.g., heating oil tanks for homes)

Heating oil tanks are a common sight in residential areas, especially in regions with cold winters. These tanks store oil used to fuel furnaces and boilers, providing consistent warmth for homes. Choosing the right oil storage tank can improve heating efficiency and reduce costs, making it a practical investment for homeowners.

Steel oil tanks are particularly well-suited for residential use due to their durability and resistance to corrosion. They are treated to withstand environmental factors, ensuring a long lifespan. This reliability makes them a preferred choice for storing oil safely in homes. Additionally, bunded oil tanks offer extra protection against leaks, safeguarding your property and the environment.

Commercial uses (e.g., fuel stations, transportation hubs)

In commercial settings, steel oil tanks are indispensable for transporting and storing fuel. Fuel stations use these tanks to store gasoline, diesel, and kerosene, ensuring a steady supply for customers. Transportation hubs, such as airports and shipping ports, rely on steel oil tanks to store large quantities of fuel for vehicles and machinery.

The design of these tanks prioritizes safety and efficiency. Bunded oil tanks are commonly used in commercial applications to prevent spills and comply with environmental regulations. Their robust construction and customizable features make them ideal for meeting the unique needs of commercial operations.

Steel oil tanks also support businesses by offering cost-effective storage solutions. Their long lifespan and minimal maintenance requirements provide excellent value over time. Whether you need a tank for gasoline, kerosene, or waste oil, steel oil tanks deliver reliable performance in commercial environments.

Agricultural uses (e.g., fuel storage for farming equipment)

Steel oil tanks play a vital role in agriculture by providing a reliable solution for storing fuel used in farming equipment. Tractors, harvesters, and irrigation pumps require a steady supply of fuel to operate efficiently. By using steel tanks, you can ensure that your farm machinery remains operational without interruptions.

One of the key advantages of steel oil tanks in agricultural settings is their durability. Farms often expose equipment to harsh conditions, including extreme weather, heavy machinery movement, and potential impacts. Steel tanks withstand these challenges better than other materials. Their robust construction resists dents and cracks, reducing the risk of leaks. Unlike fiberglass tanks, steel tanks can also be repaired easily, saving you time and money in the long run.

Tip: Regularly inspect your steel tank for signs of wear to maximize its lifespan and prevent unexpected issues.

Steel tanks also offer enhanced safety features that are crucial for farms. Many models include bunded designs, which provide an additional layer of protection against spills. This feature helps you comply with environmental regulations and protects your soil and water sources from contamination. For farms that rely heavily on fuel, these safety measures are invaluable.

Another benefit of steel oil tanks is their ability to store large volumes of fuel. This capacity allows you to buy fuel in bulk, which can lower costs and reduce the frequency of refueling trips. Bulk storage also ensures that you have enough fuel on hand during busy seasons, such as planting or harvesting.

| Feature | Benefit for Agriculture |

|---|---|

| Durability | Resists harsh conditions, reducing the risk of leaks or damage. |

| Safety Features | Prevents spills and protects the environment. |

| Large Storage Capacity | Enables bulk fuel purchases, saving costs and ensuring availability during peak seasons. |

| Easy Maintenance | Repairs are straightforward, minimizing downtime and expenses. |

Steel oil tanks are a practical investment for any farm. Their reliability and efficiency make them an essential tool for managing fuel storage. By choosing a steel tank, you can focus on your agricultural operations without worrying about fuel shortages or environmental risks.

Note: Always consult with a professional to ensure proper installation and compliance with local regulations.

Advantages of Steel Oil Tanks Over Other Materials

Durability and long lifespan

Steel oil tanks offer unmatched durability, making them a reliable choice for long-term oil storage. Their robust construction resists wear and tear, even under challenging conditions. Unlike plastic tanks, steel tanks withstand extreme temperatures and UV exposure without degrading. This durability ensures that your tank remains functional for decades, reducing the need for frequent replacements.

Steel tanks also resist impacts and structural failures better than other materials. For example, farms and industrial sites often expose tanks to heavy machinery and harsh weather. Steel tanks endure these conditions without cracking or denting, providing consistent performance. Their longevity makes them a cost-effective investment for storing oil and fuel.

Tip: Regular maintenance, such as cleaning and inspecting for rust, can extend the lifespan of your steel oil tank even further.

Resistance to theft and environmental factors

Steel oil tanks provide better security compared to alternatives like plastic or fiberglass. Their sturdy design makes them difficult to tamper with, offering protection against theft. Bunded tanks, which include a secondary containment layer, add an extra level of security. This feature ensures that your oil remains safe, even in high-risk areas.

Environmental factors like heavy rain, snow, and strong winds can damage weaker tanks. Steel tanks resist these challenges, maintaining their integrity in harsh conditions. Their ability to withstand environmental stress makes them ideal for outdoor storage. For instance, bunded steel tanks prevent leaks during storms, protecting the surrounding soil and water sources.

Steel tanks also comply with strict environmental regulations, ensuring safe oil storage. Their design minimizes the risk of spills, safeguarding both your property and the environment. By choosing steel, you gain peace of mind knowing your tank offers superior protection.

Cost-effectiveness and value over time

Steel oil tanks deliver excellent value over time. Their long lifespan reduces replacement costs, saving you money in the long run. Unlike plastic tanks, steel tanks can be repaired easily, minimizing downtime and expenses. This cost-effectiveness makes them a practical choice for storing oil and fuel.

Bulk storage is another advantage of steel tanks. Their large capacity allows you to purchase oil in bulk, lowering costs and ensuring a steady supply. For farms and businesses, this feature is invaluable during peak seasons. Steel tanks also retain their resale value, making them a flexible investment.

Note: Bunded tanks offer additional savings by preventing spills and reducing cleanup costs.

Steel tanks require minimal site preparation, further reducing installation expenses. Their durability and better security make them a smart choice for long-term oil storage. Whether you need a tank for residential, commercial, or agricultural use, steel tanks provide reliable performance and cost-effective solutions.

Customization options for specific needs

Steel oil tanks offer a wide range of customization options, allowing you to tailor them to your unique storage requirements. Whether you need a tank for industrial, residential, commercial, or agricultural use, manufacturers can adapt the design, size, and features to suit your specific needs. This flexibility ensures that your tank performs efficiently and safely in any environment.

1. Size and Capacity Adjustments

One of the most common customization options is adjusting the size and capacity of the tank. You can choose from compact tanks for residential heating oil storage or large-capacity tanks for industrial fuel needs. Manufacturers can design tanks to hold anywhere from a few hundred gallons to several thousand gallons of liquid. This flexibility allows you to optimize storage space and reduce the frequency of refueling.

Example: A small farm might require a 500-gallon tank for seasonal fuel storage, while a transportation hub may need a 10,000-gallon tank to support daily operations.

2. Material Selection

Steel oil tanks can be crafted from different types of steel, such as carbon steel or stainless steel, depending on the liquid being stored. Stainless steel tanks are ideal for storing corrosive substances or liquids that require a high level of purity. Carbon steel tanks, on the other hand, are more cost-effective and suitable for non-corrosive liquids like diesel or heating oil.

| Material | Best For |

|---|---|

| Stainless Steel | Corrosive liquids, food-grade storage, or environments with high humidity. |

| Carbon Steel | Non-corrosive liquids like diesel, kerosene, or heating oil. |

3. Shape and Orientation

The shape and orientation of your tank can also be customized to fit your space and operational needs. You can choose between vertical and horizontal tanks, depending on the available installation area. Vertical tanks save ground space and are ideal for tight locations, while horizontal tanks provide easier access for maintenance and refueling.

Tip: If you have limited space, consider a vertical tank with a smaller footprint. For easier access, a horizontal tank might be a better choice.

4. Special Coatings and Linings

To enhance durability and compatibility, you can request special coatings or linings for your steel oil tank. These coatings protect the tank from corrosion, chemical reactions, and environmental damage. For example, epoxy linings are commonly used for tanks storing water or chemicals, while oil tanks may require a rust-resistant coating to extend their lifespan.

5. Bunded Designs for Extra Safety

If you need additional protection against leaks and spills, bunded tanks are an excellent option. These tanks feature a secondary containment layer that captures any liquid escaping from the primary tank. Bunded designs are especially useful in industries where environmental compliance is critical.

Note: Many local regulations require bunded tanks for storing hazardous liquids. Always check your area’s guidelines before purchasing a tank.

6. Custom Fittings and Accessories

Steel oil tanks can also be equipped with custom fittings and accessories to improve functionality. You can add features like:

- Level Gauges: Monitor the liquid level inside the tank.

- Vents and Filters: Ensure proper airflow and prevent contamination.

- Heating Coils: Maintain the temperature of the stored liquid.

- Smart Monitoring Systems: Track usage and detect leaks in real-time.

These accessories make your tank more efficient and easier to manage, saving you time and effort.

7. Mobility Features

For applications requiring frequent relocation, you can opt for mobile steel oil tanks. These tanks come with built-in wheels or skids, making them easy to transport. Mobile tanks are particularly useful for construction sites, plant hire companies, and agricultural operations.

Example: A construction company might use a mobile tank to supply fuel to machinery across multiple job sites.

8. Compliance with Industry Standards

Customization also ensures that your tank meets industry-specific standards and regulations. Manufacturers can design tanks to comply with certifications like API 650, ISO 9001, or EU CE, depending on your operational requirements. This guarantees safety, reliability, and legal compliance.

By choosing a customized steel oil tank, you gain a storage solution tailored to your exact needs. Whether you prioritize size, safety, or special features, customization ensures that your tank delivers optimal performance in any setting.

Takeaway: Work closely with a trusted manufacturer to explore all customization options. This collaboration ensures that your tank meets your operational goals while adhering to safety and environmental standards.

Types of Steel Oil Tanks

Aboveground steel oil tanks

Aboveground steel oil tanks (ASTs) are installed on the surface, making them easy to access and maintain. These tanks are popular for their straightforward installation process and cost-effectiveness. You can use them in various industries, including agriculture, transportation, and energy. Their visibility allows for quick inspections, ensuring any issues like leaks or corrosion are detected early.

Modern ASTs often include advanced features to enhance their performance. For example, IoT sensors monitor critical parameters such as temperature and pressure, improving safety. Automated supervision systems detect leaks or structural weaknesses early, reducing risks and downtime. These features optimize maintenance and ensure compliance with safety standards. The growing demand for secure storage solutions across industries has further increased the appeal of ASTs.

| Performance Metric | Description |

|---|---|

| IoT Sensors | Enable monitoring of critical parameters like temperature and pressure for enhanced safety. |

| Automated Supervision Systems | Facilitate early detection of leaks and structural weaknesses, reducing risks and downtimes. |

| Maintenance Optimization | Automated systems ensure tanks are maintained effectively, enhancing safety and compliance. |

| Growing Market Demand | Increased need for secure storage options across various industries boosts the appeal of ASTs. |

Underground steel oil tanks

Underground steel oil tanks (USTs) are buried below the surface, making them ideal for locations with limited space. These tanks are commonly used in residential and commercial settings where aesthetics or space constraints are a concern. By being hidden underground, they minimize visual clutter and free up surface area for other uses.

USTs are designed to withstand underground pressures and environmental factors. Their construction includes corrosion-resistant coatings to prevent damage from soil and moisture. Regular inspections and maintenance are essential to ensure their longevity and safety. While USTs require more effort during installation, their discreet placement and large storage capacity make them a practical choice for many applications.

Single-walled vs. double-walled tanks

When choosing between single-walled and double-skinned oil tanks, you must consider your storage needs and safety requirements. Single-walled tanks consist of one layer of steel, making them lighter and more affordable. However, they lack additional protection against leaks, so they are best suited for areas with low environmental risks.

Double-skinned tanks, on the other hand, feature two layers of steel. This design provides an extra barrier, reducing the risk of leaks and spills. Double-skinned oil tanks are ideal for industries that prioritize safety and environmental compliance. They are especially useful in agriculture and industrial settings where accidental spills could harm the environment. By investing in a double-skinned tank, you gain peace of mind knowing your stored liquids are secure.

Tip: Always check local regulations to determine whether a single-walled or double-skinned tank is required for your application.

Specialty tanks for unique applications

Steel oil tanks can be customized for unique applications, offering solutions tailored to specific industries and operational needs. Specialty tanks are designed to meet challenges that standard tanks cannot address. These tanks provide enhanced functionality, safety, and efficiency for specialized storage requirements.

1. Tanks for Hazardous Liquids

Specialty tanks handle hazardous liquids like chemicals, biofuels, or industrial waste. Manufacturers use stainless steel with corrosion-resistant coatings to ensure safety. These tanks often include advanced sealing systems to prevent leaks. For example, chemical plants rely on these tanks to store acids and solvents securely.

Tip: If you work with hazardous substances, choose tanks with reinforced linings and compliance certifications like ISO 14001.

2. Cryogenic Tanks for Extreme Temperatures

Cryogenic tanks store liquids at extremely low temperatures, such as liquefied natural gas (LNG) or liquid nitrogen. These tanks feature insulated walls to maintain temperature stability. Industries like healthcare and energy use cryogenic tanks for applications requiring precise temperature control.

| Feature | Benefit |

|---|---|

| Insulated Walls | Prevents heat transfer, maintaining low temperatures. |

| Temperature Monitoring | Ensures safe storage of cryogenic substances. |

3. Mobile Tanks for Transport

Mobile steel tanks are ideal for transporting liquids across locations. These tanks include wheels or skids for easy movement. Construction companies and disaster relief teams use mobile tanks to supply fuel or water in remote areas.

Example: A mobile tank can deliver fuel to machinery at a construction site without disrupting operations.

4. Food-Grade Tanks for Purity

Food-grade tanks store liquids like milk, wine, or edible oils. Stainless steel ensures purity and prevents contamination. Beverage manufacturers use these tanks to maintain product quality during storage and processing.

Specialty tanks adapt to unique challenges, making them indispensable for industries with specific storage needs. By choosing the right tank, you ensure safety, efficiency, and compliance with industry standards.

Steel Fuel Storage Tanks in Different Industries

Forestry and agriculture

Steel fuel storage tanks play a vital role in forestry and agriculture. You rely on these tanks to store fuel for tractors, harvesters, and other machinery essential for daily operations. Their durability ensures they withstand harsh outdoor conditions, including heavy rain, snow, and impacts from equipment. This reliability minimizes downtime and keeps your farm or forestry equipment running smoothly.

In agriculture, bulk fuel storage helps you save costs by purchasing fuel in larger quantities. Steel tanks offer the capacity to store thousands of gallons, ensuring you have enough fuel during peak seasons like planting or harvesting. Their corrosion-resistant coatings protect the stored fuel from contamination, maintaining its quality over time.

Forestry operations also benefit from steel tanks. These tanks provide a secure way to store fuel for chainsaws, logging trucks, and other equipment used in remote areas. Their robust construction resists damage from environmental factors, making them ideal for rugged terrains.

Tip: Regularly inspect your tank for signs of wear to extend its lifespan and prevent unexpected issues.

Construction and plant hire

Steel fuel storage tanks are indispensable in construction and plant hire industries. You depend on these tanks to store fuel for excavators, cranes, and other heavy machinery. Their structural durability ensures they perform reliably in demanding environments, including construction sites exposed to extreme temperatures and heavy equipment movement.

Industry analyses highlight the advantages of steel tanks in these sectors. Their corrosion resistance protects the stored fuel from environmental damage, while their cost-effectiveness reduces operational expenses. Steel tanks are easy to maintain and repair, allowing you to focus on your projects without worrying about fuel storage issues.

Mobile steel tanks are particularly useful in construction. These tanks can be transported across job sites, ensuring a steady fuel supply for machinery. Their portability saves time and effort, making them a practical choice for plant hire companies.

Note: Always ensure your tank complies with local safety regulations to avoid penalties and ensure safe operations.

Haulage and transportation

Steel fuel storage tanks are essential for haulage and transportation industries. You use these tanks to store fuel for trucks, buses, and other vehicles that require a consistent supply to operate efficiently. Their large storage capacity allows you to refuel fleets quickly, reducing downtime and improving productivity.

Steel tanks provide enhanced security for fuel storage. Their sturdy construction resists tampering, protecting your fuel from theft. Bunded designs add an extra layer of safety by preventing spills, ensuring compliance with environmental regulations.

Transportation hubs, such as airports and shipping ports, also benefit from steel tanks. These tanks store fuel for airplanes, ships, and ground vehicles, ensuring uninterrupted operations. Their robust design withstands the demands of high-traffic areas, making them a reliable choice for large-scale fuel storage.

Takeaway: Investing in steel fuel storage tanks improves efficiency and safety in haulage and transportation operations.

Installation and Maintenance of Steel Oil Tanks

Key factors to consider before installation

Proper installation begins with selecting the right location. You must ensure the site complies with legal requirements and avoids obstructing entrances or windows. Stable surfaces are essential to prevent movement; concrete or reinforced stone bases work best. In areas prone to flooding or high winds, additional anchoring strengthens the tank’s stability.

Environmental hazards like falling debris or strong winds can damage tanks. Protect the tank by choosing a sheltered location or installing barriers. Regular inspections of the tank legs help identify rust or structural damage early. These precautions ensure the tank remains secure and functional over time.

Proper installation practices

Effective installation practices enhance the tank’s performance and safety. Start by ensuring the tank is level and securely anchored. Support legs should rest on reinforced bases to prevent shifting. Check the outlet pipe for proper alignment to allow oil to flow freely.

During installation, inspect the tank for dents, rust, or wet spots. Address these issues immediately to avoid future leaks. Conduct tests to verify the tank’s structural integrity and functionality. Following these steps ensures the tank operates efficiently and reduces the risk of costly repairs.

Maintenance tips to prevent rust and corrosion

Preventing rust and corrosion requires consistent care. Install dehumidifiers or air circulation systems to reduce moisture inside closed tanks. Insulation minimizes condensation on the tank’s surface, especially in humid environments. For tanks in coastal or industrial areas, select coatings resistant to salt and pollutants.

Regular inspections, both ultrasonic and visual, help assess the tank’s condition. Repair corrosion promptly by cleaning the affected area, applying a primer, and recoating. Use polyurethane coatings for interior surfaces to prevent reactions with stored substances. Exterior surfaces benefit from protective coatings combined with cathodic protection systems. Monitor and replace sacrificial anodes regularly to maintain effective leak prevention.

Tip: Tighten bolts and apply MIC-resistant epoxy coatings to extend the tank’s lifespan. For severe damage, carbon fiber composite patches provide durable repairs.

Common issues and troubleshooting

Steel oil tanks are durable, but they can face common issues that affect their performance. Identifying these problems early helps you maintain your tank and avoid costly repairs. Below are some frequent issues and practical troubleshooting tips.

1. Rust and Corrosion

Rust weakens the tank’s structure and can lead to leaks. Corrosion often occurs when moisture builds up inside or outside the tank. You can prevent this by applying protective coatings and inspecting the tank regularly. If you notice rust spots, clean the area with a wire brush and apply a rust-resistant primer.

Tip: Install a dehumidifier near the tank to reduce moisture levels and prevent corrosion.

2. Leaks and Spills

Leaks can result from cracks, loose fittings, or damaged seals. Check the tank’s surface for wet spots or oil stains. Tighten loose bolts and replace worn-out seals immediately. For cracks, use epoxy or carbon fiber patches to seal the damage.

| Issue | Troubleshooting Step |

|---|---|

| Loose fittings | Tighten bolts and connections. |

| Cracks | Apply epoxy or carbon fiber patches. |

| Damaged seals | Replace seals with new ones. |

3. Blocked Pipes or Valves

Blocked pipes disrupt the flow of oil and reduce efficiency. Dirt or debris often causes these blockages. Inspect the pipes and valves for obstructions. Use a pipe cleaner or compressed air to clear the blockage.

Note: Regular cleaning prevents debris buildup and ensures smooth oil flow.

4. Tank Settling or Movement

Improper installation can cause the tank to shift or settle unevenly. This movement stresses the tank and may lead to leaks. Check the tank’s base for cracks or instability. Reinforce the foundation with concrete or stone to stabilize the tank.

By addressing these issues promptly, you ensure your steel oil tank remains safe and functional. Regular inspections and maintenance reduce risks and extend the tank’s lifespan.

Environmental and Safety Considerations for Oil Storage Tanks

Compliance with environmental regulations

You must comply with environmental regulations when using an oil storage tank. These rules protect water sources, soil, and air from contamination caused by oil spills. The Spill Prevention, Control, and Countermeasure (SPCC) Rule under the Clean Water Act requires facilities storing significant amounts of oil to develop SPCC Plans. These plans outline steps to prevent spills from reaching navigable waters. Regular inspections and secondary containment measures are essential to meet these requirements.

Environmental health and safety (EHS) audits also play a key role in compliance. Internal audits help identify gaps in meeting permit requirements. Third-party audits provide unbiased assessments of environmental risks and suggest improvements. By following these guidelines, you ensure your oil storage tank operates safely and meets legal standards.

Tip: Train employees annually on SPCC protocols to ensure preparedness and compliance.

Safety measures for handling and storage

Handling and storing oil safely requires careful planning. You should place your oil storage tank on a stable surface to prevent movement. Reinforced bases like concrete or stone work best. Install barriers to protect the tank from falling debris or strong winds. These measures reduce the risk of accidents and damage.

Equip your tank with safety features like level gauges and vents. Level gauges help monitor oil levels, preventing overfilling. Vents ensure proper airflow, reducing pressure buildup inside the tank. Bunded tanks offer extra protection by containing spills within a secondary layer. These features enhance safety and minimize environmental risks.

Note: Always inspect fittings and seals for wear and replace them promptly to avoid leaks.

Preventing and managing spills or leaks

Preventing spills starts with regular maintenance. Inspect your oil storage tank for rust, cracks, or loose fittings. Apply protective coatings to prevent corrosion. Tighten bolts and replace damaged seals immediately. These steps keep your tank secure and reduce the risk of leaks.

If a spill occurs, act quickly to minimize damage. Use absorbent materials like sand or specialized pads to contain the oil. Notify local authorities if the spill threatens water sources or public safety. Proper cleanup ensures compliance with environmental regulations and protects your property.

Takeaway: Bunded tanks and secondary containment measures are effective tools for managing spills.

Innovations in Steel Oil Tank Design

Modern advancements in tank technology

Steel oil tanks have evolved significantly with modern technology. Manufacturers now use advanced materials and techniques to improve tank performance. For example, laser welding creates stronger seams, reducing the risk of leaks. You can also find tanks with modular designs, which allow for easier transportation and assembly. These features make installation faster and more efficient.

Another innovation is the use of corrosion-resistant coatings. These coatings protect the tank from rust, even in harsh environments. Tanks designed for extreme conditions, such as arctic or desert climates, now include thermal insulation. This feature ensures the stored oil remains stable, regardless of external temperatures.

Tip: Look for tanks with certifications like API 650 or ISO 9001. These standards guarantee quality and safety.

Eco-friendly and energy-efficient designs

Sustainability has become a priority in steel oil tank design. Many tanks now include eco-friendly features to reduce environmental impact. For instance, manufacturers use recycled steel to produce tanks, lowering the carbon footprint. You can also choose tanks with double-walled designs, which prevent leaks and protect the surrounding soil and water.

Energy efficiency is another focus. Some tanks come with integrated solar panels to power monitoring systems. Others use reflective coatings to minimize heat absorption, reducing the need for cooling systems. These innovations help you save energy while maintaining safe storage conditions.

Note: Eco-friendly tanks often qualify for tax incentives or rebates. Check local programs to see if you can benefit.

Smart monitoring systems for better management

Smart technology has transformed how you manage steel oil tanks. Modern tanks now include sensors that monitor liquid levels, temperature, and pressure in real time. These sensors send data to your smartphone or computer, allowing you to track tank performance remotely.

Some systems also include leak detection features. If a leak occurs, the system alerts you immediately, helping you take quick action. Predictive maintenance tools analyze data to identify potential issues before they become serious. This technology reduces downtime and repair costs.

Takeaway: Investing in smart monitoring systems improves safety and efficiency. It also gives you peace of mind knowing your tank is always under control.

Choosing the Right Steel Oil Tank for Your Needs

Assessing your storage requirements

Choosing the right steel oil tank starts with understanding your storage needs. Begin by evaluating the type and quantity of liquid you plan to store. For residential use, smaller tanks may suffice for heating oil. Industrial applications often require larger tanks to accommodate high volumes of fuel or chemicals. Consider the available space at your site. Aboveground tanks work well in open areas, while underground tanks save surface space in crowded locations.

Think about environmental factors. If your tank will be exposed to harsh weather, opt for models with corrosion-resistant coatings. For areas prone to flooding, bunded tanks provide extra protection against spills. Assessing these factors ensures your tank performs efficiently and safely.

Tip: Consult local regulations to determine the required tank type and size for your area.

Comparing different tank options

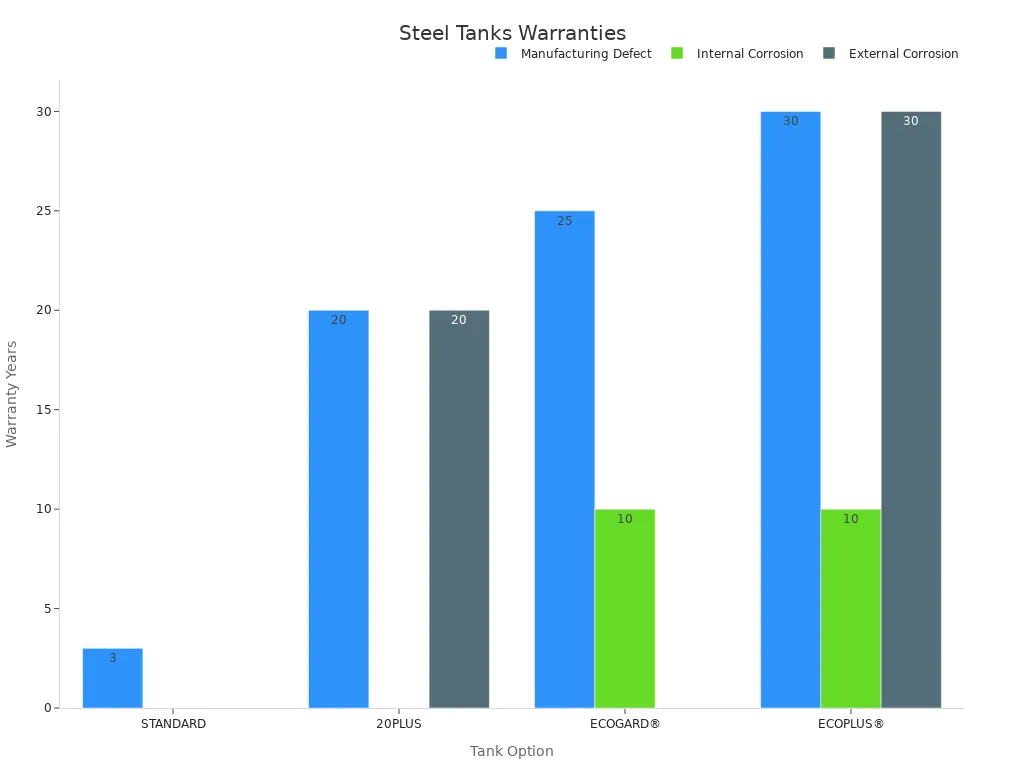

Steel oil tanks come in various designs, each offering unique benefits. Comparing options helps you find the best fit for your needs. Below is a table summarizing popular tank options and their warranties:

| Tank Option | Description | Warranty (Manufacturing Defect) | Warranty (Internal Corrosion) | Warranty (External Corrosion) |

|---|---|---|---|---|

| STANDARD | GOOD Single Wall | 3 years | N/A | N/A |

| 20PLUS | BETTER Single wall with polyurethane coating | 20 years | N/A | 20 years |

| ECOGARD® | BEST Double-bottom system with leak detection | 25 years | 10 years | N/A |

| ECOPLUS® | TOP Double bottom + polyurethane coating | 30 years | 10 years | 30 years |

When comparing tanks, prioritize durability and safety features. Double-bottom tanks like ECOGARD® and ECOPLUS® offer superior leak prevention. Tanks with polyurethane coatings resist external corrosion, making them ideal for outdoor storage. Longer warranties indicate higher quality and reliability, ensuring your investment lasts.

Working with trusted manufacturers and suppliers

Partnering with reputable manufacturers ensures you receive a high-quality steel oil tank. Look for companies with certifications like ISO 9001 or EU CE, which guarantee adherence to safety and quality standards. Manufacturers like Shandong Chenma Machinery Co., Ltd. specialize in customizing tanks to meet specific needs. Their expertise in engineering and technical services ensures your tank performs optimally.

Suppliers with strong customer support provide added value. They assist with installation, maintenance, and troubleshooting, making the process seamless. Choose suppliers who offer warranties and after-sales services to protect your investment.

Takeaway: Collaborating with trusted manufacturers and suppliers ensures your tank meets industry standards and delivers reliable performance.

Steel oil tanks provide a dependable solution for storing oil and other liquids across diverse industries. Their durability and strength make them a preferred choice for applications ranging from agriculture to transportation. Advanced designs enhance performance, ensuring safety and reliability in demanding environments.

| Evidence | Description |

|---|---|

| Durability and Strength | Steel is widely used for its unmatched durability and strength in storage. |

| Performance Enhancement | Tanks improve reliability and safety for heavy off-road vehicles. |

| Design Complexity | Designing steel tanks requires expertise in material properties and safety. |

| Advanced Analysis Methods | Modern analysis methods ensure robust and safe tank designs. |

| Pressure Testing | Materials like CR-2 D are tested for pressure resistance in tank construction. |

By understanding the uses and benefits of a steel oil tank, you can make informed decisions tailored to your needs. Whether for residential or industrial purposes, these tanks deliver long-term value and security.

FAQ

What is the lifespan of a steel oil tank?

A steel oil tank typically lasts 20 to 30 years with proper maintenance. Regular inspections, protective coatings, and rust prevention measures can extend its lifespan. Environmental factors like humidity and temperature also influence durability.

How do you maintain a steel oil tank?

Inspect the tank regularly for rust, leaks, or structural damage. Clean the tank to remove sediment buildup. Apply protective coatings to prevent corrosion. Tighten bolts and replace worn seals. For underground tanks, monitor for soil moisture to avoid external corrosion.

Are steel oil tanks environmentally friendly?

Steel oil tanks are eco-friendly when designed with double walls or bunded systems. These features prevent leaks and protect soil and water. Many manufacturers use recycled steel, reducing environmental impact. Proper maintenance ensures compliance with environmental regulations.

Can steel oil tanks be customized?

Yes, steel oil tanks offer extensive customization options. You can adjust size, shape, and material to fit your needs. Add features like bunded designs, level gauges, or smart monitoring systems. Custom coatings enhance durability for specific environments.

What safety features should a steel oil tank have?

Look for tanks with bunded designs, leak detection systems, and level gauges. Vents ensure proper airflow, reducing pressure buildup. Corrosion-resistant coatings and reinforced bases improve safety. Smart monitoring systems provide real-time alerts for leaks or structural issues.