Understanding the structures of fermentation tanks is crucial for anyone involved in wine, cider, or beer

production. Fermentation tanks are sophisticated vessels engineered with specific components that ensure optimal

fermentation conditions, maintain product quality, and facilitate efficient operation. This comprehensive guide

explores the essential structural elements, materials, design features, and technical specifications that make

fermentation tanks effective for beverage production across various scales.

Table of Contents

Basic Structure Components

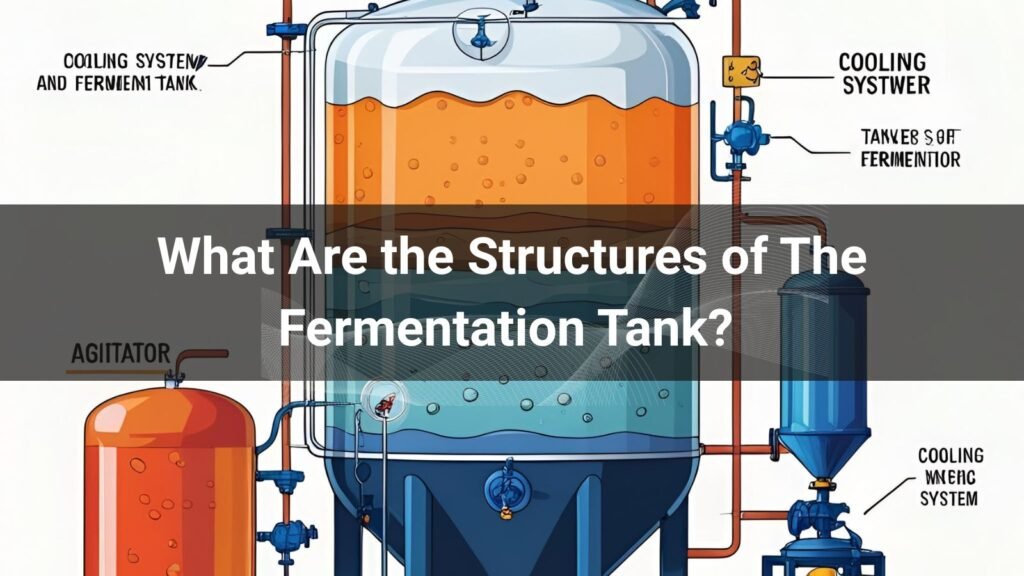

The fundamental structure of a fermentation tank consists of several critical components that work together to

create an optimal environment for fermentation processes. Understanding these basic elements is essential for

selecting the right equipment for your specific application.

Primary Structural Elements

Every fermentation tank incorporates specific structural components designed to maintain integrity under pressure

while providing functionality for the fermentation process. The head plate forms the top of the

tank and is typically constructed from 3mm SS304 stainless steel to withstand internal pressure variations. The

body of the tank, also made from 3mm SS304 stainless steel, provides the main containment volume

and must be engineered to handle the stress of liquid contents and fermentation gases.

| Component | Material | Thickness | Primary Function |

|---|---|---|---|

| Head Plate | SS304 Stainless Steel | 3mm | Top closure and pressure containment |

| Body Shell | SS304 Stainless Steel | 3mm | Main containment vessel |

| Bottom Section | SS304 Stainless Steel | 3-4mm | Sediment collection and drainage |

| Support Structure | SS304 Stainless Steel | Variable | Weight distribution and stability |

The bottom section of fermentation tanks varies significantly depending on the intended application.

Conical bottom tanks feature a 60-degree conical bottom that allows yeast and sediment to settle

naturally, facilitating easy removal without disturbing the liquid above. This design is particularly beneficial for

wine and cider production where sediment separation is crucial for product clarity.

Materials and Construction Methods

The choice of materials and construction methods directly impacts the performance, longevity, and safety of

fermentation tanks. Modern fermentation vessels utilize advanced materials and sophisticated welding techniques to

ensure optimal results.

Stainless Steel Specifications

Food-grade 304 stainless steel remains the gold standard for fermentation tank construction due to its exceptional

properties. This material offers excellent corrosion resistance, ease of cleaning, and neutral flavor impact on the

fermentation process. The selection of SS304 ensures that tanks can withstand the acidic conditions common in wine

and cider fermentation while maintaining structural integrity over many years of use.

Professional manufacturers like Shandong Chenma Machinery Co., Ltd. employ advanced construction

techniques to maximize the performance of their fermentation equipment. Located in Shandong Province, Chenma

utilizes a combination of automated robotic welding and hand-crafted welds executed through tungsten inert gas (TIG)

processes. This sophisticated approach results in joints that are exceptionally strong, smooth, and sanitary.

Welding and Surface Treatment

The welding process represents a critical aspect of fermentation tank construction. 100% TIG

welding ensures consistent, high-quality joints that can withstand the stresses of fermentation while

maintaining sanitary conditions. Following welding, tanks undergo polishing and passivation treatment on all metal

surfaces, creating a smooth finish that resists bacterial growth and facilitates thorough cleaning.

Surface treatment extends beyond aesthetics to functional necessity. The polished interior surfaces prevent the

accumulation of residues that could harbor contaminants, while the passivated surface develops a protective oxide

layer that enhances corrosion resistance. This attention to surface quality directly impacts the longevity of the

equipment and the quality of the final product.

Tank Shapes and Configurations

Fermentation tank shapes have evolved to optimize different aspects of the fermentation process, with each

configuration offering specific advantages for particular applications. Understanding these variations helps in

selecting the most appropriate design for specific production needs.

Cylindrical Tanks

Cylindrical fermentation tanks represent the most common configuration for large-scale production. These wine fermentation tanks provide excellent structural

strength and efficient use of space while offering uniform pressure distribution throughout the vessel. The

cylindrical shape facilitates even temperature distribution and allows for efficient cooling system integration.

Conical Bottom Designs

The incorporation of conical bottoms in fermentation tanks serves multiple functional purposes. The angled bottom

promotes natural sediment settlement, concentrating yeast and other particles at the lowest point for easy removal.

This design feature is particularly valuable in wine production where sediment management directly affects product

quality and clarity.

Variable Capacity Options

Modern fermentation facilities often require flexibility in batch sizes, leading to the development of variable capacity wine tanks. These innovative

designs allow operators to adjust the effective volume of the tank to match production requirements, optimizing

space utilization and reducing waste from partially filled vessels.

| Tank Shape | Best Application | Key Advantages | Capacity Range |

|---|---|---|---|

| Cylindrical | Large-scale production | Structural strength, space efficiency | 1,000L – 50,000L+ |

| Conical Bottom | Wine and cider | Sediment management, easy cleaning | 500L – 20,000L |

| Variable Capacity | Flexible production | Batch size adaptability | 1,000L – 10,000L |

| Square/Rectangular | Space-constrained facilities | Maximum space utilization | 500L – 5,000L |

Cooling Systems and Temperature Control

Temperature control represents one of the most critical aspects of fermentation tank design, as proper temperature

management directly influences fermentation kinetics, flavor development, and product quality. Modern fermentation

tanks incorporate sophisticated cooling systems to maintain optimal conditions throughout the fermentation process.

Dimple Jacket Systems

The dimple jacket cooling system consists of an exterior shell constructed from 1.5mm to 2mm SS304

stainless steel that creates a space for coolant circulation around the tank body. This design provides efficient

heat transfer while maintaining the structural integrity of the primary vessel. The dimple pattern increases surface

area contact between the coolant and the tank wall, enhancing cooling efficiency.

Spiral Cooling Channels

An alternative to dimple jackets, spiral cooling channels wind around the exterior of the tank in a helical

pattern. This configuration offers excellent temperature uniformity and can be particularly effective for smaller

tanks where precise temperature control is essential. The spiral design ensures that coolant contacts the entire

surface area of the tank systematically.

Insulation Systems

Professional-grade fermentation tanks incorporate comprehensive insulation systems to maintain temperature

stability and improve energy efficiency. Polyurethane insulation injected to an 80mm thickness

provides excellent thermal properties while protecting the cooling system from ambient temperature fluctuations.

This insulation significantly reduces energy consumption and helps maintain consistent fermentation conditions.

Access Points and Maintenance Features

Proper access points and maintenance features are essential for the practical operation of fermentation tanks.

These elements enable effective cleaning, inspection, sampling, and product transfer while maintaining sanitary

conditions throughout the process.

Manways and Access Ports

Fermentation tanks incorporate multiple access points designed for specific functions. The top manhole

cover provides access for tank interior inspection and cleaning, while side rectangle

manways offer convenient entry points for maintenance activities. These access points feature knobs for

easy opening and include gasket systems to ensure proper sealing when closed.

Outlet Systems

Professional fermentation tanks feature multiple outlet systems to facilitate different operational requirements.

The primary wine outlet allows for product transfer at the completion of fermentation, while the

drain outlet enables complete tank emptying for cleaning and maintenance. Sample

valves permit quality control testing without compromising the main product volume.

CIP (Clean-In-Place) Systems

Modern fermentation tanks integrate sophisticated CIP systems that combine rotating spray balls with pressure

gauges, pressure adjusting apparatus, arms, and valves. This system ensures thorough cleaning without requiring tank

disassembly, maintaining sanitary conditions while reducing downtime between batches.

Specialized Features for Different Applications

Different fermentation applications require specific features tailored to the unique requirements of each process.

Understanding these specialized components helps in selecting equipment optimized for particular production goals.

Wine-Specific Features

Wine fermentation tanks often incorporate features designed to enhance the specific requirements of wine

production. These may include punch-down devices for red wine cap management, must

pumps for grape processing, and specialized lees stirring systems to enhance flavor

extraction during aging processes.

Cider Production Adaptations

For cider fermentation, tanks may feature specialized ports for

fruit addition, enhanced sediment management systems for apple pulp removal, and temperature control systems

optimized for the specific requirements of apple fermentation. The design considerations for cider tanks often emphasize easy cleaning due to the higher fiber

content in apple-based fermentations.

Carbonation and Pressure Systems

Some fermentation tanks incorporate systems for natural or forced carbonation, including carb

stones installed at the tank bottom for efficient CO2 dissolution. Pressure regulation systems allow for

controlled fermentation environments and can facilitate the production of sparkling beverages through secondary

fermentation processes.

Quality Standards and Certifications

Professional fermentation tank manufacturers adhere to strict quality standards and maintain relevant

certifications to ensure their equipment meets industry requirements. These standards govern materials, construction

methods, safety features, and performance specifications.

International Certifications

Leading manufacturers like Shandong Chenma Machinery maintain comprehensive certification programs including

ISO9001-2005 quality system certification, ISO14001-2015 environmental management system

certification, and OHSAS18001-2007 occupational health management system certification.

Additionally, EU CE certification ensures compliance with European safety and quality standards.

Material Standards

Fermentation tanks must utilize materials that meet food-grade specifications and maintain their properties under

fermentation conditions. SS304 stainless steel must conform to relevant ASTM standards for chemical composition,

mechanical properties, and corrosion resistance. Surface finish specifications ensure that interior surfaces meet

sanitary requirements for food and beverage production.

Selection Considerations for Different Industries

Selecting the appropriate fermentation tank structure requires careful consideration of multiple factors including

production volume, product type, available space, and operational requirements. Each industry presents unique

challenges that influence design priorities.

Capacity Planning

Production capacity requirements directly influence tank size selection and structural specifications. Small craft

operations may benefit from tanks ranging from 1BBL to moderate commercial sizes, while large-scale production

facilities require vessels capable of handling thousands of liters. The scalability of operations should be

considered to ensure that initial equipment investments can accommodate future growth.

Space Optimization

Facility layout considerations significantly impact tank shape and configuration selection. Cylindrical tanks offer

excellent space efficiency for open floor areas, while square or rectangular tanks may provide better space

utilization in constrained environments. The height limitations of facilities may necessitate horizontal tank

configurations or the use of multiple smaller vessels.

Process Requirements

Different fermentation processes require specific structural features. Wine production benefits from conical bottom

tanks that facilitate sediment management, while beer production may require pressure-capable vessels for

conditioning processes. Chemical mixing applications

demand tanks with specialized agitation systems and material compatibility considerations.

Professional Support and Service

The selection of fermentation equipment should consider the availability of professional support and service.

Established manufacturers with comprehensive service networks can provide ongoing technical support, spare parts

availability, and maintenance services that ensure long-term operational success.

For those seeking professional guidance in fermentation tank selection and design, experienced manufacturers offer

consultation services to help match equipment specifications with operational requirements. Contact Shandong Chenma Machinery Co., Ltd. for expert advice

on fermentation tank structures and custom design solutions. Reach out via WhatsApp at

008618063421809 or email admin@sdchenma.com to discuss your specific fermentation equipment

needs.

Located in Pingyuan County Economic Development Zone, Dezhou City, Shandong Province, Chenma operates a 20,000 m² production facility equipped with

state-of-the-art machinery capable of producing even the most technically demanding designs. Their team of over 200

professionals specializes in manufacturing stainless steel tanks and processing equipment for the alcohol, food, and beverage industries.

Understanding fermentation tank structures enables informed decision-making when investing in equipment for wine,

cider, beer, or other fermented beverage production. The integration of proper materials, construction methods,

cooling systems, and specialized features ensures optimal fermentation conditions and long-term operational success.

By working with experienced manufacturers who maintain quality certifications and provide comprehensive support

services, producers can achieve their production goals while maintaining the highest standards of product quality

and safety.