You achieve perfect fermentation by choosing wine fermentation tank dimensions that fit your batch size, wine style, and goals. Most commercial wineries use tanks from 250 gallons to 8,000 gallons, but custom options can reach up to 25,000 gallons. When you match tank size to your batch volume, you improve fermentation control and save energy. Temperature-controlled tanks also help you maintain quality and consistency. Chenma’s custom stainless steel tanks let you tailor your setup for the best results every time.

Why Tank Size Matters

Fermentation Quality

You want your wine to taste its best. The size of your fermentation tank plays a big role in this. Scientific studies show that tank size affects how well you control temperature, oxygen, and the movement of solids during the wine fermentation process. These factors change the flavor, aroma, and texture of your wine. For example, larger tanks can keep temperatures steady, which helps yeast work better and protects wine quality. Smaller tanks let you make quick adjustments, but they may not hold heat as well. The shape and material of the tank also matter, but size is a key factor you should not ignore.

Stainless steel tanks come in many sizes, from small to very large. This lets you pick the right tank for your needs. When you use the right size, you get better control over oxygen and temperature. This leads to more consistent and higher-quality wine. Concrete tanks also offer benefits. Their thick walls keep temperatures steady and allow gentle oxygen flow, which can add complexity to your wine.

Tip: Always match your fermentation tank size to your production goals. This helps you keep your wine quality high and your process efficient.

Batch Volume

Choosing the right tank size for your batch volume is important. If your tank is too small, you risk spills and messy overflows during active fermentation. If your tank is too big, you may have too much empty space, which can let in extra oxygen and spoil your wine. You should leave about 25% of the tank empty to allow for foaming and solids. This space helps prevent oxidation and keeps your wine safe.

- Tanks that fit your batch size make it easier to control temperature and mix the wine.

- Variable capacity tanks give you flexibility for different batch sizes.

- The right tank size helps you keep your wine’s aroma, color, and flavor strong.

Matching your fermentation tank to your batch volume supports a smooth workflow and makes cleaning easier. It also helps you scale up production without losing quality.

Wine Fermentation Tank Dimensions

Standard Sizes

You need to understand standard wine fermentation tank dimensions before you choose the right fermenter for your winery. The industry uses a wide range of fermenter sizes, from small tanks for boutique wineries to massive tanks for large-scale production. The material and shape of the fermenter also affect your wine’s quality and the efficiency of your process.

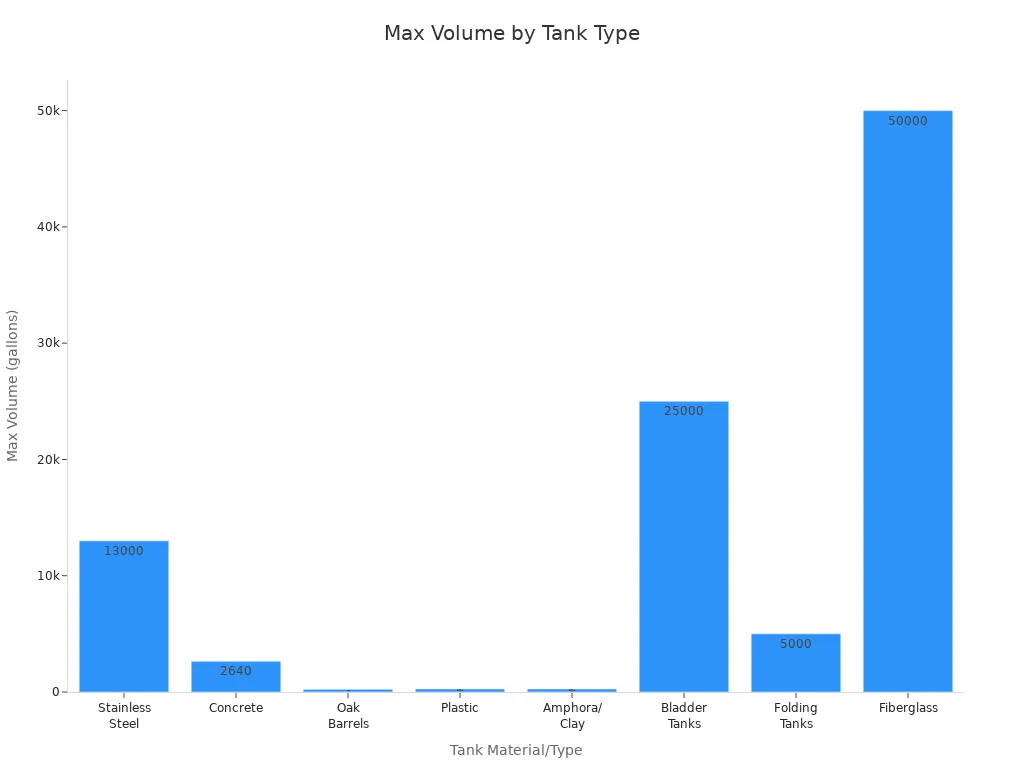

Here is a table that shows the typical tank sizes and features for different materials and winery scales:

| Tank Material/Type | Typical Volume Range | Common Shapes and Features | Usage Context |

|---|---|---|---|

| Stainless Steel | 500 to 13,000 gallons (1,900 to 49,000 liters) | Truncated cone tops, flat or sloping floors, cooling jackets, multiple ports | Small to large wineries; flexible and precise temperature control |

| Concrete | 300 to 10,000 liters (80 to 2,640 gallons) | Egg, amphora, conical, square, tower; embedded cooling | Boutique to mid-size wineries; stable temperature, unique micro-oxygenation |

| Oak Barrels | 225 to 860 liters (60 to 227 gallons) | Barrel shape | Premium wines, small batch aging |

| Plastic | 20 to 1,000 liters (5 to 264 gallons) | Food-grade, lightweight, stackable | Small-scale or experimental batches |

| Amphora/Clay | 30 to 1,000+ liters (8 to 264+ gallons) | Narrow base, broad shoulder, narrow neck | Artisanal, small-scale fermentation and aging |

| Bladder Tanks | 25 to 25,000 gallons | Portable, customizable | Temporary or flexible use |

| Folding Tanks | 500 to 5,000 gallons | Quick setup | Emergency or limited capacity |

| Fiberglass | 4,000 to 50,000 gallons | Durable, moderate cost | Large-scale production |

You can see that stainless steel fermenters offer the widest range of tank sizes and capacity. These tanks work well for both small and large wineries. Concrete and oak fermenters add unique flavors but come in smaller sizes. Plastic and amphora fermenters suit small or experimental batches.

When you select a fermenter, match the fermenter size to your production needs. For boutique wineries, you might use fermenters from 60 to 264 gallons. Mid-size wineries often choose fermenters between 600 and 1,000 gallons. Large wineries use fermenters that hold 1,320 to 26,400 gallons or more. Stainless steel wine fermentation tanks give you the most flexibility if you plan to scale up.

Headspace Guidelines

Headspace is the empty space at the top of your fermenter. Managing headspace is critical for safe and high-quality fermentation. Too much headspace can let in oxygen, which may spoil your wine. Too little can cause messy overflows during active fermentation.

Follow these guidelines to manage headspace in your wine fermentation tank:

- Leave about 25% of the fermenter empty during primary fermentation. This space allows for foaming and cap development.

- During secondary fermentation, minimize headspace to 1–2 inches (2.5 to 5 cm) to reduce oxygen exposure.

- Always match your fermenter size to your wine volume. This reduces unnecessary headspace and protects your wine.

- If you have excess headspace, top up with similar wine or use inert gases like nitrogen or argon to displace oxygen.

- Seal your fermenter tightly with an airlock or bung to prevent oxygen from entering.

- For small adjustments, you can add distilled water or a mix of distilled water and vodka to reduce headspace without changing the wine’s flavor.

- If you still have too much headspace, transfer your wine to a smaller fermenter or use sanitized glass marbles to displace air.

Tip: Always check your fermenter during active fermentation. Adjust headspace as needed to prevent overflow and oxidation.

By following these headspace guidelines, you protect your wine from spoilage and ensure a clean, controlled fermentation. The right wine fermentation tank dimensions and careful headspace management help you produce consistent, high-quality wine every time.

Choosing a Wine Fermentation Tank

Batch Size

When you start choosing a wine fermentation tank, you need to match the fermenter size to your batch volume. This step helps you avoid problems like spills or too much empty space. If you use a fermenter that is too small, you risk losing wine during active fermentation. If you pick a fermenter that is too large, you create extra headspace, which can lead to oxidation and spoilage.

You should look at several factors to consider when choosing a wine tank for your batch size:

- Sample valve: Lets you take samples for testing or tasting without opening the fermenter and risking contamination.

- Cooling jacket: Helps you control the temperature inside the fermenter. This feature keeps yeast healthy and prevents off-flavors.

- Thermometer and thermowell: Allow you to check the temperature inside the fermenter accurately while keeping everything clean.

- Leveling feet: Make sure your fermenter sits flat and drains well.

- Fermentation manway: Gives you easy access for cleaning and removing grape solids, which is important for red wine.

- Pump over system: Moves wine over the grape cap during red wine fermentation. This process breaks up solids and controls pressure.

You also need to think about the physical space in your winery. Make sure you can move around the fermenter and reach all the fittings. If you plan to grow your production, choose a fermenter size that gives you room to expand.

Tip: Always match your fermenter size to your batch volume. This step helps you keep your wine safe and your process efficient.

Wine Style

The style of wine you want to make changes the type of fermenter you need. Each wine style has its own needs for temperature, mixing, and oxygen control. You should match your fermenter features to the wine you plan to produce.

Here is a table that shows how different wine styles affect your fermenter choice:

| Wine Style | Fermentation Characteristics | Implications for Fermenter Design and Features |

|---|---|---|

| Red Wine | Fermented with skins, seeds, sometimes stems; needs punch-down or pump-over; warmer temps | Needs mixing systems, space for solids cap, strong temperature control |

| White Wine | Fermented without skins; no punch-down; cooler temps | Needs precise temperature control, no mixing system required |

| Orange Wine | Made from white grapes with skins; similar to red wine fermentation | Needs mixing systems and temperature control, space for solids |

| Rosé Wine | Limited skin contact; processed like white wine; lighter color and flavor | Needs temperature control, simple design, minimal mixing |

If you make red wine, you need a fermenter with a pump over system or a way to punch down the grape cap. You also need strong temperature control because red wine ferments at higher temperatures. For white wine, you want a fermenter that keeps the temperature cool and steady. You do not need a mixing system because you do not ferment with skins. Orange wine needs features similar to red wine, while rosé wine uses a simpler fermenter like white wine.

You should also think about the material of your fermenter. Stainless steel works well for most wine styles because it is easy to clean and gives you good temperature control. Oak barrels add flavor and allow some oxygen in, which can help red wines. Clay or ceramic pots allow gentle oxygen flow but need more care.

Note: The right fermenter helps you control the process and get the best results for your chosen wine style.

How Tank Dimensions Affect Fermentation

Temperature Control

You need to pay close attention to temperature control when you choose a fermenter. The size and shape of your fermenter change how well you can manage heat during fermentation. Scientific studies show that fermenter materials and heating methods make a big difference. Tanks made from better insulating materials can keep the inside up to 2.85°C warmer than older materials. If you use artificial heating, like heat exchangers or under-floor air heating, you can raise the temperature by as much as 8.12°C. This means your fermenter’s construction and thermal management tools directly affect how you control temperature.

Tank geometry also matters. For example, Maule found that cylindro-conical tanks have different temperatures at the cone bottom and the top. Larson and Brandon measured temperature in Uni-Tanks and showed that tank shape changes how heat moves inside. Schuch studied three fermenters and found temperature differences up to 1.5°C near the tank walls. Takamoto and Saito discovered that tank design creates wavy convection patterns, which affect temperature control. Even the placement of your temperature sensor can change your readings.

Tip: Always check your fermenter’s temperature at different spots. This helps you spot hot or cold zones and keep your fermentation tank at the right temperature.

Oxygen Exposure

Oxygen exposure in your fermenter depends on the surface area-to-volume ratio. Smaller fermenters have a higher ratio, so more wine touches the air. This can help with heat loss but also increases the risk of too much oxygen. Larger fermenters have a lower ratio, so less wine is exposed to air per unit volume. This means you get less oxygen in your wine, which can be good for some styles.

- Smaller fermenters cool down faster but let in more oxygen.

- Larger fermenters hold heat better and limit oxygen exposure.

- The design of your fermenter, such as open-top or closed-top, also changes how much air gets in.

You can manage oxygen by filling headspace with inert gas or using a closed fermenter. The surface area-to-volume ratio shapes the physical environment inside your fermentation tank. It affects both temperature control and oxygen levels. Vessel design, like open-top fermenters, allows more air contact, while closed tanks help you limit oxygen.

Note: Always match your fermenter’s size and design to your wine style and temperature control needs. This helps you keep oxygen at the right level and protect your wine’s flavor.

Features of Wine Fermentation Tanks

Material Options

When you choose wine fermentation tanks, you need to think about the material. Each material changes how your wine ferments and how easy it is to clean the tank. Stainless steel fermentation tanks are the most popular choice in modern wineries. They resist corrosion, clean easily, and give you excellent temperature control. You can use them for many wine styles because they do not add flavors to your wine. High-quality stainless wine tank options also last for many years and keep your wine safe from outside odors.

You may see other materials like concrete, plastic, wood, or clay. Each has its own strengths and weaknesses. The table below helps you compare them:

| Material | Advantages | Disadvantages |

|---|---|---|

| Stainless Steel | Durable, easy to clean, precise temperature control, keeps wine flavor pure | Higher cost, does not add flavor |

| Concrete | Good temperature control, softens texture with micro-oxygenation | Harder to clean, less durable |

| Plastic | Affordable, lightweight, easy to move | Short lifespan, risk of chemical leaching |

| Wooden | Adds flavor and aroma, smooths texture | Needs more cleaning, expensive |

| Amphorae (Clay) | Unique flavors, gentle oxygen flow | Fragile, costly, best for small batches |

Plastic fermentation tanks work well for small or experimental batches. They cost less and are easy to move, but you need to check that they are food-grade to avoid chemical risks. If you want a tank that fits your exact needs, Chenma offers custom stainless steel fermentation tanks with many capacity options.

Tip: Stainless steel fermentation tanks give you the best mix of safety, durability, and temperature control for most wineries.

Fittings and Accessories

Modern wine fermentation tanks come with many features to help you control the process. You find fittings like cooling jackets, which let you manage temperature control by circulating coolant around the tank. Integrated sensors track temperature and sugar levels, so you always know how your fermentation is going. High-quality stainless wine tank designs often include sampling valves, making it easy to test your wine without opening the tank.

You also see mixers or agitators in some tanks. These help keep the temperature even and make sure yeast and sugar mix well. Airlocks and breather valves let carbon dioxide escape but keep out air, protecting your wine from spoilage. Many stainless steel fermentation tanks have conical bottoms, which help you remove yeast and solids easily. Some tanks include manholes and sight glasses for easy inspection and cleaning.

Custom tanks from Chenma can include advanced features like automated control panels, pressure gauges, and cleaning systems. These options help you make better wine with less effort.

Note: The right fittings and accessories make your wine fermentation tanks easier to use and help you produce high-quality wine every time.

Choose the Right Wine Fermentation Container

Home Winemaking

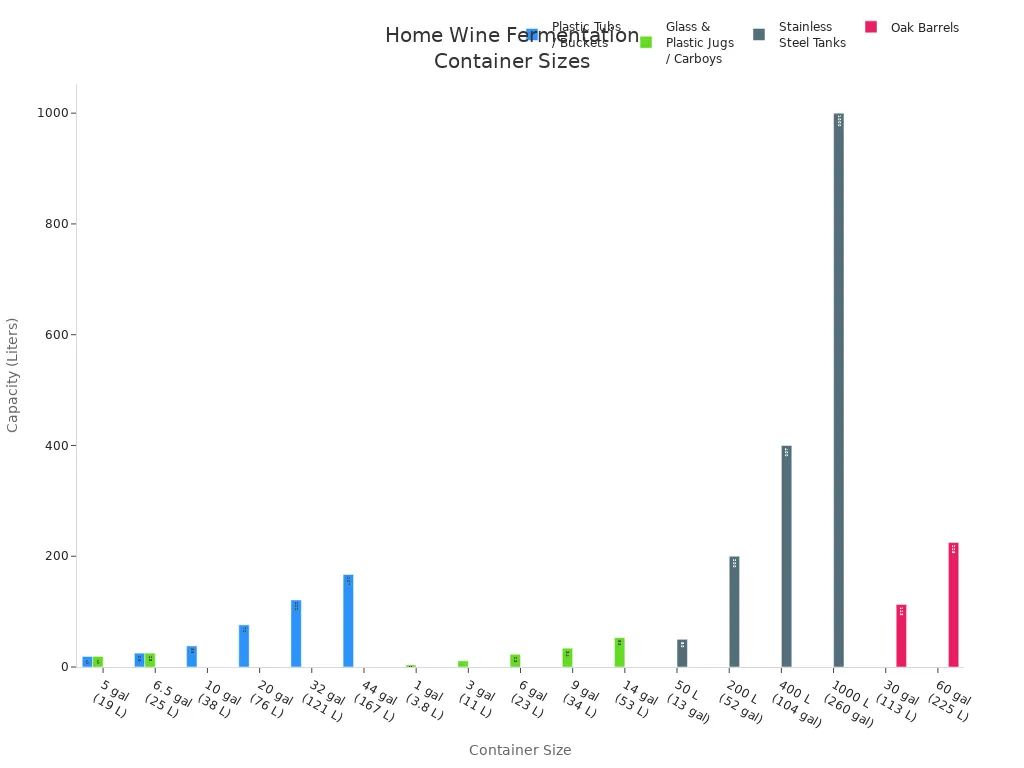

When you start making wine at home, you need to choose the right wine fermentation container for your batch size and style. Most home winemakers use small fermenters that are easy to handle and clean. You often work with batches from 5 to 20 liters, so you do not need large equipment. Here are some popular options for home wine fermenters:

- Plastic tubs or buckets: These come in sizes like 5, 6.5, 10, and 20 gallons. They are lightweight, food-safe, and easy to use for red wine fermentation.

- Glass or plastic carboys: Glass carboys range from 1 to 14 gallons. Plastic PET carboys are less fragile and come in similar sizes. Both work well for white wine fermentation and aging.

- Stainless steel fermenters: These start at 13 gallons and go up to 260 gallons. They are easy to clean and last a long time. Some have variable capacity lids for flexibility.

- Oak barrels: Standard barrels hold 60 gallons. They add flavor and are best for aging, not primary fermentation.

| Container Type | Typical Sizes / Capacities | Material Characteristics & Notes |

|---|---|---|

| Plastic Tubs / Buckets | 5 gal (19 L), 6.5 gal (25 L), 10 gal (38 L), 20 gal (76 L), 32 gal (121 L), 44 gal (167 L), half-ton bins (~454 kg) | Food-grade, open top, easy to handle, best for red wine fermentation. |

| Glass & Plastic Carboys | Glass: 1-14 gal (3.8-53 L); Plastic: 3-6.5 gal (11-25 L) | Inert, oxygen barrier, suitable for white wine fermentation and aging. |

| Stainless Steel Tanks | 13-260 gal (50-1,000 L) | Inert, easy to clean, variable capacity, suitable for all wine styles. |

| Oak Barrels | 60 gal (225 L), 30 gal (113 L) | Adds flavor, used for aging. |

You can choose the right wine fermentation container by thinking about your batch size, wine style, and how much space you have. For most home winemakers, plastic buckets or glass carboys work best for small batches. Stainless steel fermenters give you more control and last longer, but they cost more.

Tip: Always clean your fermenter well before and after use to keep your wine safe and tasty.

Commercial Production

If you run a winery, you need to choose the right wine fermentation container for larger batches and more complex needs. Commercial wine fermenters come in many sizes, from hundreds to thousands of gallons. You often use stainless steel, concrete, or oak tanks. Each material changes the taste and texture of your wine.

Commercial fermenters have special features to help you control the process:

- Cooling jackets keep the temperature steady during fermentation.

- Sample valves let you test your wine without opening the tank.

- Fermentation manways make cleaning and removing grape solids easy.

- Pump over systems help mix the wine and manage solids for red wine.

- Tank stands and washers help with setup and cleaning.

You need to pick a fermenter that fits your production space and budget. Stainless steel wine fermenters are popular because they are durable, easy to clean, and allow precise temperature control. Concrete tanks offer stable temperatures and gentle oxygen flow. Oak tanks add flavor and are used for special wines.

Note: Advanced commercial fermenters often include automated temperature controls and digital monitoring. These features help you make consistent, high-quality wine at scale.

When you choose the right wine fermentation container for your winery, think about your wine style, batch size, and future growth. The right fermenter helps you keep your wine safe, control quality, and work efficiently.

Comparing Tank Shapes

Cylindrical vs. Conical

You often see two main shapes for wine fermentation tanks: cylindrical and conical. Each shape offers unique benefits for your winemaking process.

Cylindrical tanks have straight sides and a flat or slightly sloped bottom. You find these tanks in many wineries because they are simple to use and easy to clean. The flat bottom lets you stir the wine and remove solids without much effort. These tanks work well for both red and white wines.

Conical tanks have a cone-shaped bottom. This design helps you collect yeast and grape solids at the tip of the cone. You can remove these solids easily through a valve. This shape makes cleaning faster and helps you keep your wine clear. Many winemakers use conical tanks for red wines because the solids settle quickly.

| Feature | Cylindrical Tank | Conical Tank |

|---|---|---|

| Bottom Shape | Flat or sloped | Cone-shaped |

| Cleaning | Easy | Very easy |

| Solids Removal | Manual | Automatic (via valve) |

| Wine Clarity | Good | Excellent |

Tip: If you want to save time on cleaning and get clearer wine, consider a conical tank.

Height-to-Diameter Ratio

The height-to-diameter ratio of your tank changes how your wine ferments. This ratio tells you how tall the tank is compared to its width.

A tall, narrow tank (high ratio) gives you less surface area at the top. This means less wine touches the air. You get less oxygen in your wine, which helps keep flavors fresh. Tall tanks also help you control temperature better because heat rises and spreads slowly.

A short, wide tank (low ratio) has more surface area at the top. More wine touches the air, so you get more oxygen. This can help red wines develop more color and flavor. However, you need to watch for too much oxygen, which can spoil the wine.

- For white wines, use tall, narrow tanks to protect delicate flavors.

- For red wines, use shorter, wider tanks to boost color and aroma.

Note: The right height-to-diameter ratio depends on your wine style and your goals for fermentation. Always match your tank shape to the wine you want to make.

Mistakes to Avoid

Over/Under Sizing

Choosing the wrong tank size can cause big problems in your winemaking process. If you pick a tank that is too small, you risk spills and messy overflows during active fermentation. You may lose valuable wine and create extra cleaning work. A tank that is too large leaves too much empty space above the wine. This extra space, called headspace, lets in more oxygen and increases the risk of spoilage.

You should always match your tank size to your batch volume. If you plan to grow your production, select a tank that fits your current needs but also allows for some expansion. Variable capacity tanks can help you handle different batch sizes without leaving too much headspace. Remember, the right tank size helps you control temperature, manage solids, and protect your wine’s flavor.

Tip: Measure your typical batch size before buying a tank. This step helps you avoid costly mistakes and keeps your wine safe.

Ignoring Headspace

Headspace is the empty area between the wine and the top of the tank. Ignoring headspace can lead to serious quality issues. Too much headspace increases oxygen exposure, which can cause your wine to spoil or lose its fresh taste. Oxygen can also help harmful microbes grow, leading to off-flavors and even wine faults.

Here are some problems that come from poor headspace management:

- Oxygen exposure causes browning and pinking in wine.

- Spoilage organisms like Klockera, Pichia, Hanseniaspora, and Candida can grow in excess headspace.

- These microbes may produce ethyl acetate, which smells like nail polish remover, and increase volatile acidity.

- Wine quality drops quickly when you do not control headspace.

You can reduce these risks by using variable capacity tanks with floating lids or by blanketing the wine with inert gas. Always check that seals are tight to prevent air from sneaking in. Good temperature control, proper sanitation, and timely processing also help keep your wine safe.

| Feature | Fixed Capacity Tank | Variable Capacity Tank (Floating Lid) |

|---|---|---|

| Headspace | Fixed headspace unless full | Minimal or eliminated at various volumes |

| Oxidation Risk | Higher when partially full | Significantly reduced |

| Flexibility | Best for consistent batch sizes | Handles varying volumes efficiently |

Note: Managing headspace is just as important as choosing the right tank size. Protect your wine by keeping headspace to a minimum and using the right equipment.

Best Practices

Sizing Checklist

Choosing the right wine fermentation tank starts with a clear plan. You want to avoid mistakes and make sure your tank fits your needs. Use this checklist to guide your decision:

- Assess your production volume. Write down how much wine you plan to make each season. This helps you match tank size to your output.

- Measure your available space. Check your winery layout. Make sure the tank will fit and leave room for movement and cleaning.

- Focus on temperature control. Pick tanks with cooling or heating systems. This keeps your fermentation steady and protects wine quality.

- Look for customization options. Choose tank shapes, sizes, and features that match your winemaking style. Consider options like oxygen management and easy cleaning.

- Balance your budget with long-term value. Stainless steel tanks last longer and need less maintenance.

- Plan for flexibility. Select tanks that can handle different batch sizes and wine styles.

- Add practical features. Sample valves and easy-access manways help with quality checks and cleaning.

- Consult with experts. Talk to manufacturers like Chenma. They can help you design custom tanks for your unique needs.

Tip: A careful checklist saves you time and money. It also helps you make better wine.

Planning for Growth

You want your winery to grow. Smart planning now makes future expansion easier. Successful wineries design their tank systems with growth in mind. They choose modular layouts that let them add new tanks without moving old ones. You can reserve space for extra tanks and install extra ports for sampling and monitoring. This makes upgrades simple and avoids costly changes later.

Many wineries set up their infrastructure with extra capacity. They install cooling lines, cleaning systems, and electrical wiring that can support more tanks in the future. You can use tall, conical-bottom tanks and multi-level platforms to save floor space. Standardized piping and utility systems help you expand without trouble.

Facility designers often suggest phased investments. You build the main infrastructure first, then add tanks as your production grows. This keeps your project on budget and lets you scale up smoothly. Always plan operator paths and safety zones so your team can work safely, even after expansion.

Note: Partner with experienced manufacturers like Chenma. Their engineers can help you design a tank system that grows with your winery and supports new wine styles.

Choosing the right wine fermentation tank size shapes your wine’s quality, efficiency, and future growth. Align your tank with your batch type and wine style for the best results:

| Batch Type | Recommended Tank Size | Typical Use Case |

|---|---|---|

| R&D or pilot | 6–15 gallons | Experimentation, training |

| Small batch | ~60 gallons | Boutique production |

| Mid-sized lot | 600–1,000 gallons | Core product lines |

| High volume | 5,000–10,000+ liters | Bulk or export production |

You gain better temperature control, easier cleaning, and flexibility when you match tank size to your needs. Use the checklist, and reach out to Chenma for custom solutions.

Tip: Always confirm certifications and plan for future expansion when selecting your tank.

FAQ

What is the best tank size for small wineries?

You should choose tanks between 250 and 1,000 gallons. These sizes fit most small winery batches. They help you control temperature and manage headspace. Stainless steel tanks in this range offer flexibility and easy cleaning.

How much headspace should I leave during fermentation?

Leave about 25% of the tank empty during primary fermentation. This space allows for foaming and solids. For secondary fermentation, reduce headspace to 1–2 inches to limit oxygen exposure.

Can I use the same tank for red and white wine?

Yes, you can use the same stainless steel tank for both. Clean the tank thoroughly between batches. Use temperature control features to match each wine style’s needs.

Why does tank shape matter in wine fermentation?

Tank shape changes how much wine touches the air and how heat moves inside. Tall, narrow tanks protect delicate flavors. Short, wide tanks help red wines develop color and aroma.

Tip: Always match your tank’s shape and size to your wine style for the best results.