You can expect the wine fermentation tank price for mid-capacity tanks to range from $7,000 to $10,000, based on recent market data for tanks holding 500 to 1,000 gallons. Several factors strongly influence the wine fermentation tank price you pay, such as material quality, tank design, and added features. The table below highlights the main points that affect cost:

| Factor | Impact on Price |

|---|---|

| Stainless Steel Grade | Higher grade, higher price |

| Tank Thickness & Design | More complex, more expensive |

| Capacity | Larger tanks cost more |

| Special Features | Add-ons increase cost |

| Brand & Service | Premium brands charge more |

Comparing prices helps you make the smartest investment for your winery.

Key Takeaways

- Wine fermentation tanks vary widely in price, from about $1,500 for entry-level small tanks to over $45,000 for high-end custom models.

- Material choice greatly affects cost; stainless steel tanks cost more upfront but last longer and offer better temperature control than plastic, oak, or concrete tanks.

- Tank size and type impact price; larger tanks and those with special features like cooling jackets or variable lids cost more but improve wine quality and flexibility.

- Brand reputation and supplier location influence price and service; well-known brands and local suppliers often provide better support and reliability.

- Smart buyers compare detailed quotes, check warranties, and match tank features to their production needs to balance cost, quality, and long-term value.

Wine Fermentation Tank Price Range

Entry-Level Wine Fermentation Tank Price: Small and Basic Options

If you are just starting out or need a basic solution, entry-level winery tanks offer an affordable way to begin wine production. Small flat-bottom wine fermentation tanks, usually under 500 gallons, cost between $1,500 and $3,000. These tanks work well for home winemakers, small wineries, or experimental batches. The price increases as you add features or choose larger sizes.

You can find a wide range of entry-level tanks from different suppliers. For example, Blichmann Engineering offers stainless steel tanks from $1,200 to $7,000. If you prefer plastic tanks, Speidel provides options from $100 to $400. Oak barrels from Wine Enthusiast range from $400 to $2,000, while Sonoma Cast Stone’s concrete tanks cost between $2,500 and $10,000.

| Supplier | Tank Type | Price Range |

|---|---|---|

| Blichmann Engineering | Stainless Steel | $1,200 – $7,000 |

| Speidel | Plastic | $100 – $400 |

| Wine Enthusiast | Oak Barrels | $400 – $2,000 |

| Sonoma Cast Stone | Concrete | $2,500 – $10,000 |

You can also compare small tank prices and features from other well-known suppliers:

| Supplier | Price Range for Small Tanks (250-500 liters) | Notes on Features |

|---|---|---|

| JVNW, Inc. | $2,000 – $6,000 | High customization, cooling |

| Paul Mueller Company | $1,500 – $5,000 | Custom designs, durability |

| Ziemann Holvrieka | $3,000 – $7,000 | Industrial-scale tanks |

| Letina | $1,500 – $4,500 | Variable-capacity tanks |

Most entry-level wine fermentation tank prices fall between $1,500 and $6,000, depending on the supplier and features. Basic tanks usually cost less, but you may pay more for extra durability or cooling options.

Tip: Entry-level tanks are a smart choice if you want to keep the cost of winery tanks low while testing new recipes or starting small.

Mid-Range Wine Fermentation Tank Price: Standard Features and Sizes

When you need more capacity and standard features, mid-range winery tanks become the best option. These tanks usually hold between 500 and 1,000 gallons and come with features like temperature control, variable capacity lids, and durable construction. The wine fermentation tank price for mid-range models typically ranges from $10,000 to $30,000.

- Most mid-range tanks cost between $10,000 and $30,000.

- Tanks in this range often include options for customization.

- Advanced features, such as temperature control, can increase the price.

- Planning your purchase helps you manage cash flow and return on investment.

- Custom tanks may have longer lead times, so order early.

Material choice also affects the price. Plastic tanks are the most affordable, while stainless steel tanks offer a balance of price and durability. Oak and concrete tanks are more expensive and often used for specialty wines.

| Tank Material | Price Range (USD) |

|---|---|

| Plastic Tanks | $100 – $400 |

| Stainless Steel | $1,200 – $7,000 |

| Oak Barrels | $400 – $2,000 |

| Concrete Tanks | $2,500 – $10,000 |

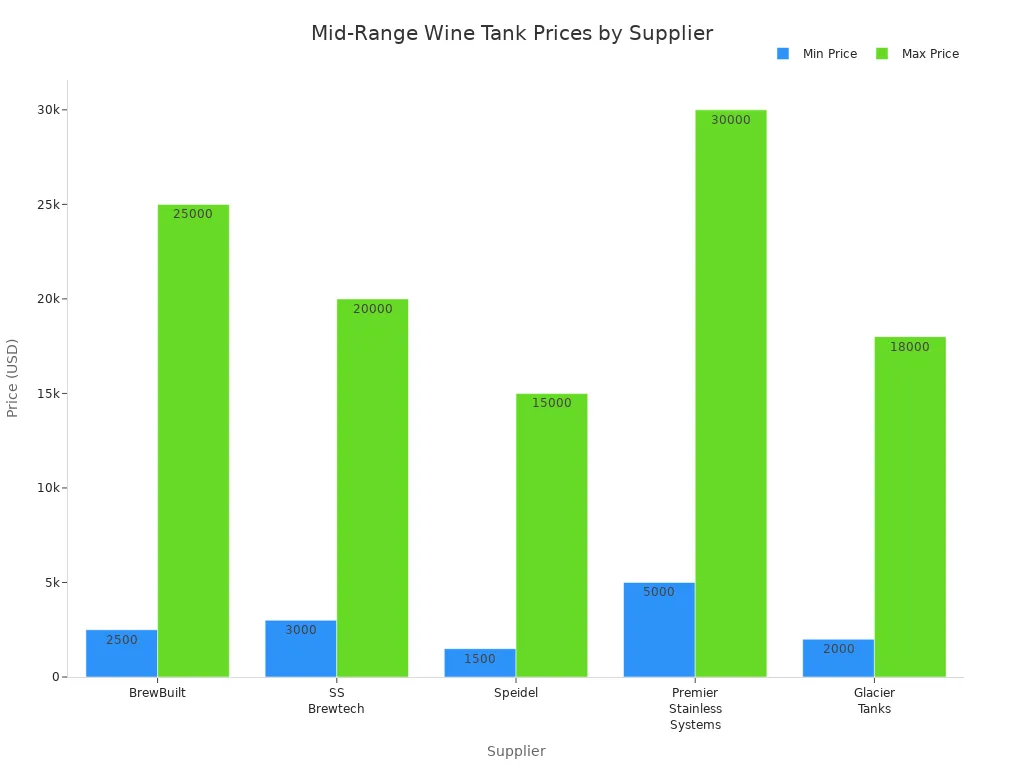

You can see how mid-range wine fermentation tank prices vary by supplier and features:

| Supplier | Price Range (USD) | Notes |

|---|---|---|

| BrewBuilt | $2,500 – $25,000 | Customizable stainless steel tanks |

| SS Brewtech | $3,000 – $20,000 | Advanced features like temperature control |

| Speidel | $1,500 – $15,000 | Durable German engineering |

| Premier Stainless Systems | $5,000 – $30,000 | High-end, extensive customization |

| Glacier Tanks | $2,000 – $18,000 | Affordable, practical for startups |

Prices for mid-range tanks depend on size, material, and features. Stainless steel tanks are common in this range because they resist corrosion and are easy to clean. Brand reputation and extra features, such as automation, can also raise the price.

High-End and Custom Wine Fermentation Tank Price

If you want the best performance and advanced features, high-end and custom winery tanks are available. These tanks use premium materials and offer features like cooling jackets, variable capacity, and airtight lids. The wine fermentation tank price for high-end models often starts at $10,000 and can exceed $45,000 for large or fully customized tanks.

| Tank Size (Gallons) | Price (USD) |

|---|---|

| 250 | $3,350 |

| 500 | $4,300 |

| 1,000 | $6,200 |

| Tank Size/Capacity | Material | Price Range (USD) |

|---|---|---|

| 5 Gallons | Stainless Steel | $150 – $300 |

| 50 Gallons | Stainless Steel | $1,000 – $2,500 |

| 500 Gallons | Stainless Steel | $5,000 – $10,000 |

| 1,000+ Gallons | Stainless Steel | $10,000 and up |

Custom tanks come in many styles, such as flat bottom, round bottom, and glycol-jacketed. You can request special features to match your production needs. Some tanks include ultra-smooth interiors, robotic-arm laser welding, and thick rubber lid gaskets for better sealing. Other features that increase the price include:

- High-grade stainless steel (304 or 316L) for durability and food safety.

- Variable capacity for flexible batch sizes.

- Airtight lids to prevent oxidation.

- Extra fittings like temperature controls and pressure monitoring.

- Large manways for easy cleaning.

- Conical bottoms for better drainage.

- Insulation for temperature stability.

- Stackability and mobility features.

| Feature | Impact on Price and Explanation |

|---|---|

| Material Grade | Use of 304 or 316 stainless steel increases cost due to corrosion resistance and food safety compliance. |

| Cooling Jacket | Adds complexity and cost by enabling precise temperature control during fermentation. |

| Capacity Options | Larger or variable sizes increase material and manufacturing costs. |

| Manway Access | Large, secure openings require better design and materials, raising price. |

| Racking Valve | Additional fittings increase manufacturing complexity and cost. |

| Sight Gauge | Visual indicators add to the tank’s features and cost. |

| Conical Bottom Design | Specialized shape aids sediment removal but adds to fabrication cost. |

| Insulation | Improves temperature stability but increases material and production expenses. |

| Stackability | Design for stacking adds engineering and manufacturing costs. |

| Mobility Features | Casters or forklift channels add to the tank’s price due to extra components and design. |

Note: High-end tanks often come with long warranties and are built to last for decades. You pay more upfront, but you gain reliability and advanced control over your winemaking process.

Main Factors Affecting Wine Fermentation Tank Price

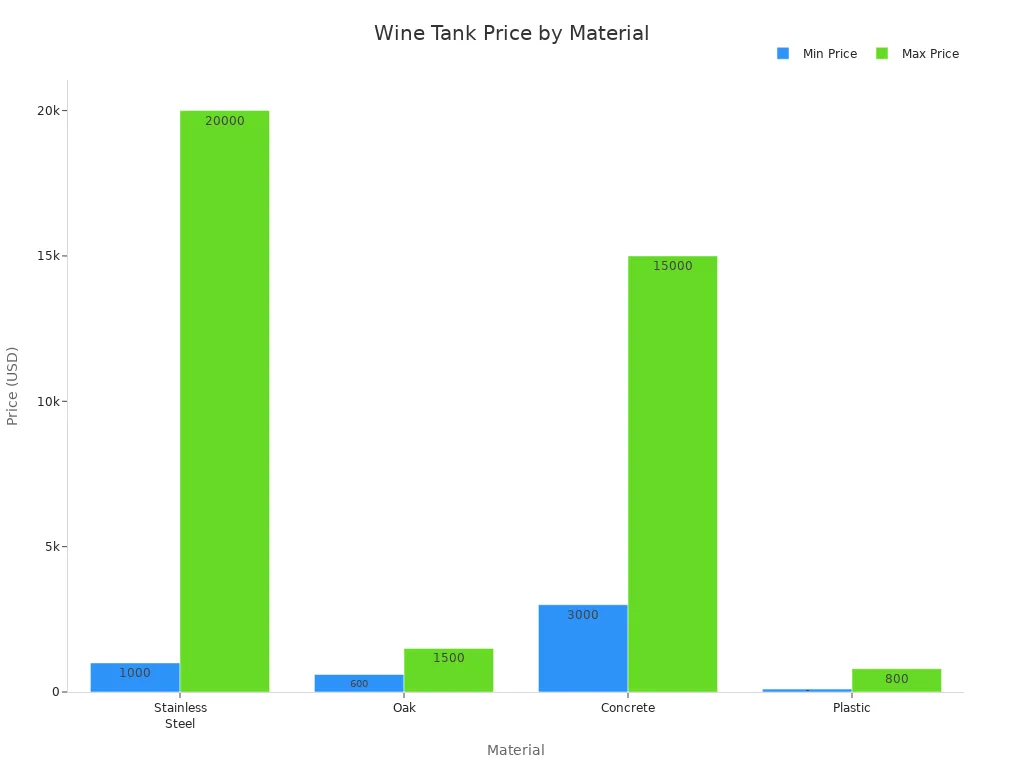

Material: Stainless Steel Wine Fermentation Tank vs. Plastic, Concrete, and Oak

When you choose a wine fermentation tank, the material plays a big role in the price. Stainless steel tanks usually cost more than other types. They last a long time, resist rust, and are easy to clean. Many winemakers like stainless steel because it helps keep the wine pure and allows for good temperature control. Oak barrels add even more to the price. The cost comes from the wood and the skill needed to make them. Oak also gives special flavors to the wine, which some winemakers want. Plastic tanks are the cheapest. They are light and easy to move, but they do not last as long. Concrete tanks fall in the middle. They are strong and can last many years, but they need some care.

Here is a table that shows how different materials compare:

| Material | Price Range (USD) | Durability | Temperature Control | Flavor Impact | Notes on Price Impact |

|---|---|---|---|---|---|

| Stainless Steel | $1,000 – $20,000 | Very High | Excellent | Neutral | Higher upfront cost due to durability and features like temperature control |

| Oak | $600 – $1,500/barrel | Medium | Low | High | Costly due to oak wood and craftsmanship; requires maintenance |

| Concrete | $3,000 – $15,000 | High | Moderate | Low | Moderate to high price; durable but requires maintenance |

| Plastic | $100 – $800 | Low | Limited | Neutral | Most affordable but less durable and may retain odors |

You can see that stainless steel wine fermentation tanks have the highest upfront cost, but they offer the best durability and features. Oak and concrete tanks cost less than stainless steel, but they need more care. Plastic tanks are the most affordable, but they do not last as long.

Tip: If you want a tank that lasts for many years and is easy to clean, stainless steel is a smart choice. If you want to save money and only make small batches, plastic might work for you.

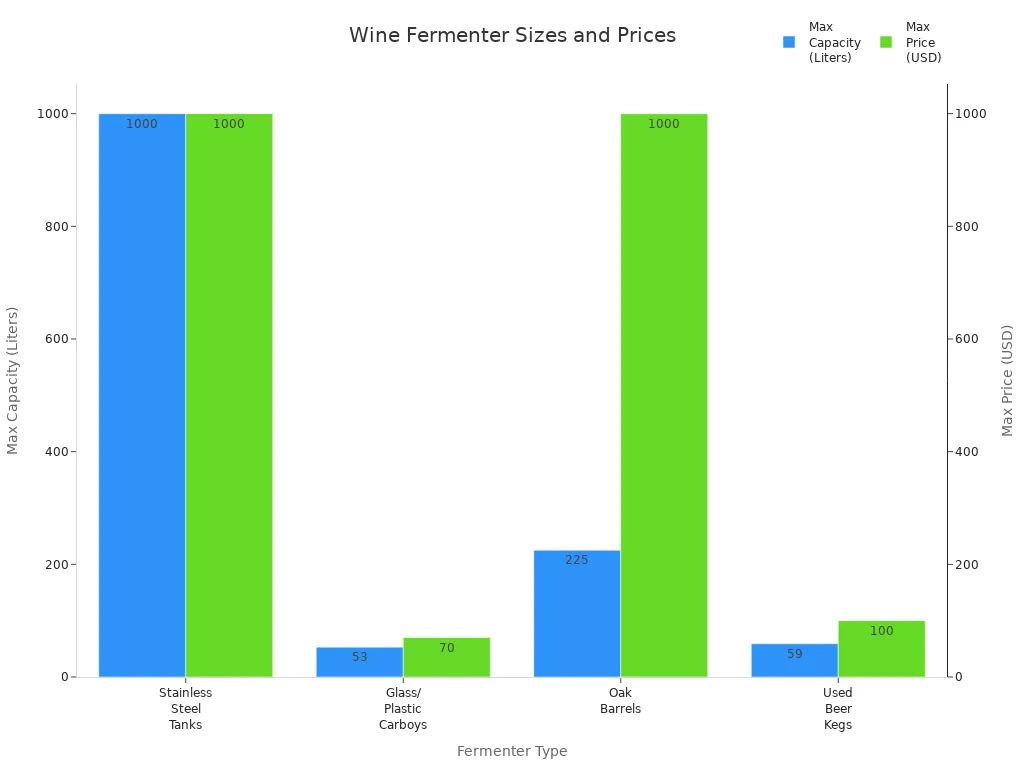

Capacity and Size of Wine Fermentation Tank

The size of your tank affects the price a lot. Small tanks cost less, but they may not hold enough wine for your needs. Large tanks cost more because they use more material and need stronger designs. If you pick a tank that is too small, you might spill wine during fermentation. If you pick a tank that is too big, you might have trouble keeping the temperature steady. You need to match the tank size to your production goals.

Here is a table that shows how tank size and price can change:

| Fermenter Type | Size Range (Liters) | Size Range (Gallons) | Price Range (USD) |

|---|---|---|---|

| Stainless Steel Tanks | 50 – 1,000 L | 13 – 260 gal | ~$300 (small) to >$1,000 (large) |

| Popular Stainless Sizes | 200 – 400 L | 52 – 104 gal | Within above range |

| Oak Barrels | 3.8 – 225 L | 1 – 60 gal | $50 (used small) to ~$1,000 (new large) |

Larger tanks also need more space in your winery. You may need to plan for extra room and special equipment to move or clean them. Some suppliers offer tanks as small as 50 liters for experiments or as large as 1,000 liters for big batches.

Note: Picking the right size helps you use your resources well and keeps your wine quality high.

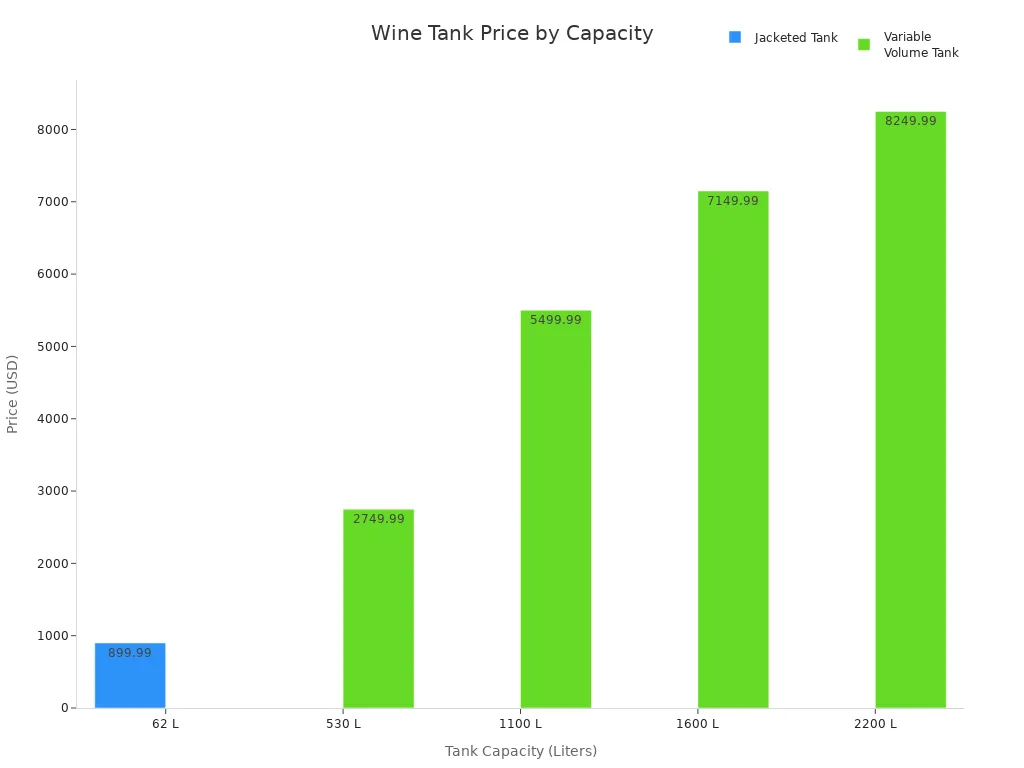

Wine Fermentation Tank Type: Open-Top, Closed, Jacketed, and Variable Capacity

The type of tank you choose also changes the price. Open-top tanks are simple and often cost less. They let you punch down the grape skins by hand, which some winemakers like. Closed tanks keep out air and help control the fermentation process. Jacketed tanks have a special layer that lets you control the temperature by running cold or hot water around the tank. These tanks cost more because of the extra parts. Variable capacity tanks have a floating lid. You can adjust the lid to fit the amount of wine inside. This helps prevent air from touching the wine. Variable capacity tanks often cost more than open-top or closed tanks, especially as they get bigger.

Here is a table with some price examples:

| Tank Type | Capacity (Liters) | Key Features | Price (USD) |

|---|---|---|---|

| Jacketed Tank | 62 | Full cooling jacket, conical bottom, laser weld | $899.99 |

| Variable Volume Tank | 530 | Partial cooling jacket, floating lid, conical bottom | $2,749.99 |

| Variable Volume Tank | 1100 | Double cooling jacket, floating lid, conical bottom | $5,499.99 |

| Variable Volume Tank | 1600 | Partial cooling jacket, floating lid, conical bottom | $7,149.99 |

| Variable Volume Tank | 2200 | Partial cooling jacket, floating lid, conical bottom | $8,249.99 |

You can see that jacketed tanks start at about $900 for small sizes. Variable capacity tanks can cost from about $2,700 to over $8,000, depending on size and features.

Tip: If you want to control the temperature closely, a jacketed tank is a good choice. If you need flexibility for different batch sizes, a variable capacity tank can help.

Brand Reputation and Region of Manufacture

When you shop for a wine fermentation tank, you will notice that brand reputation plays a big role in the price. Well-known brands often charge more because they have a history of quality and reliability. These brands invest in better materials and skilled workers. You can expect tanks from top brands to last longer and come with better support.

Region of manufacture also affects the cost. Tanks made in countries with advanced technology, like the United States or Germany, usually cost more. These regions have strict quality standards and use high-grade stainless steel. Tanks from these areas often include advanced features and precise engineering.

Tanks made in other regions, such as China, can offer great value. Companies like Shandong Chenma Machinery Co., Ltd. use modern equipment and skilled engineers to produce high-quality tanks. You can find both standard and custom tanks from these suppliers. Many buyers choose tanks from these regions to balance quality and price.

Tip: If you want a tank that lasts for many years, look for brands with a strong reputation and check where the tank is made. This helps you get the best value for your money.

Customization and Special Features in Wine Fermentation Tanks

You may need a tank that fits your unique winemaking process. Customization lets you choose the shape, size, and features that match your needs. When you ask for custom options, the price can change a lot. Custom shapes, special lids, and unique dimensions all add to the cost. Some wineries need tanks with special heights or diameters to fit their space. Others want tanks with sealed tops or variable volume lids.

Here is a table that shows common customization options and how they affect price:

| Customization Option | Examples / Details | Price Impact / Notes |

|---|---|---|

| Tank Shape | Round, Parallelpiped, Arco, Tronco-Piramidale, Venus, Opale, Diamante | Custom shapes increase price due to complexity |

| Lid Style | Sealed Top, Variable Volume | Custom lids add to cost |

| Tank Dimensions | Diameter (14 in. to 35 in.), Height (up to 8 ft.) | Size affects price; larger tanks cost more |

| Material | Concrete (custom-made), Stainless Steel (standard stackable) | Concrete tanks range $8,900-$11,000; stainless steel ~$4,600 |

| Custom Build | Tailored to winery/brewery needs | Requires consultation; price varies significantly |

| Accessories | Breathable ferment covers ($23-$44) | Minor cost, not part of tank customization |

Special features can also raise the price. If you want temperature control, automation, or a glycol jacket, you will pay more. Basic tanks cost less, but they do not have these advanced features. Tanks with heating and cooling modes or sediment removal systems cost between $1,000 and $5,000. Large tanks with full automation and advanced controls can cost $10,000 or more.

| Fermenter Type | Features Included | Price Range (USD) |

|---|---|---|

| Small Scale | Basic tanks, simple construction | $100 – $500 |

| Mid-Range | Heating & cooling modes, sediment removal | $1,000 – $5,000 |

| Large Scale | Full automation, temperature control, glycol jackets, PLC systems | $10,000 – $100,000+ |

A 500-liter automatic tank with temperature control can cost between $1,700 and $2,750. This shows that special features make a big difference in price.

Note: Customization and special features help you make better wine, but you should plan your budget carefully. Always ask for a detailed quote before you buy.

Comparing Top Wine Fermentation Tank Suppliers

Choosing the right fermentation tank supplier can help you get the best value for your winery. You will find many options in the market, each with unique strengths and product ranges. Let’s look at three leading suppliers and what they offer.

SDCHENMA: Stainless Steel Wine Fermentation Tank Product Range and Value

SDCHENMA stands out as a trusted name among fermentation tank suppliers. You can find a wide range of stainless steel tanks designed for wine, cider, and other beverages. SDCHENMA uses advanced machinery and skilled engineers to create both standard and custom tanks. You can choose from different sizes, shapes, and features to match your production needs. The company offers turnkey solutions, including process design and technical support. Many buyers select SDCHENMA for its balance of quality, flexibility, and competitive pricing. If you want reliable winery tanks that fit your budget and requirements, SDCHENMA gives you many options.

Tip: SDCHENMA’s ability to customize tanks helps you adapt to changing production goals.

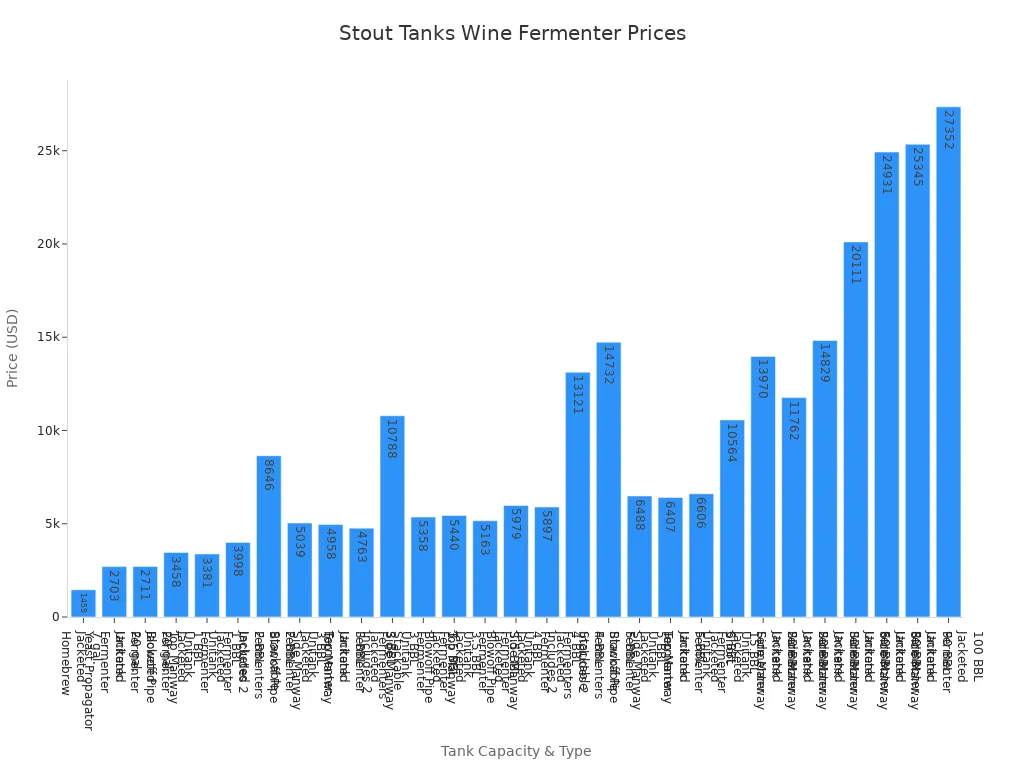

Stout Tanks: Strengths and Wine Fermentation Tank Price Points

Stout Tanks offers a large selection of jacketed and stackable fermenters. You can pick from small homebrew tanks to large commercial units. Stout Tanks focuses on quality construction and temperature control. Prices start at about $1,459 for a 7-gallon jacketed fermenter and go up to over $27,000 for a 100-barrel unitank. The company provides many options for manways, blowoff pipes, and stackable designs.

You can see that as tank size increases, the price rises. Stout Tanks is a good choice if you want a wide range of sizes and features.

BrewBuilt: Specialty Wine Fermentation Tank Offerings

BrewBuilt focuses on specialty winery tanks for both small and large producers. You can find tanks with advanced features like glycol jackets, variable capacity lids, and easy-to-clean designs. BrewBuilt’s tanks work well for wineries that need precise temperature control and flexibility. The company offers both off-the-shelf and custom solutions. Many winemakers choose BrewBuilt for its attention to detail and strong support for specialty projects.

Note: When you compare fermentation tank suppliers, look at their specialties, price ranges, and ability to meet your unique needs.

| Rank | Supplier Name (Country) | Specialties | Reasons to Choose / Highlights |

|---|---|---|---|

| 1 | Pretank (China) | Open-top, closed, pump-over fermenters, forkable tanks | Competitive pricing, high craftsmanship, custom fittings, export-ready |

| 2 | Gortani Srl (Italy) | Thermoregulated fermenters, vinificators, truncated cone | Precise temperature control, automated cap management, used by top Italian wineries |

| 3 | Letina (Croatia) | Open/closed tanks, variable capacity with floating lids | Flexible solutions, ideal for small to medium wineries, strong in North America and Europe |

| 4 | Speidel (Germany) | Jacketed, conical, flat-bottom tanks | German precision engineering, durable design, temperature control options |

| 5 | Santa Rosa Stainless Steel (USA) | Red/white wine fermenters, open and closed-top conical tanks | California-based, custom high-end tanks for Napa & Sonoma wineries |

| 6 | SK Škrlj (Slovenia) | Custom fermenters for still and sparkling wines | Modular design, CE certified, strong Eastern Europe presence |

| 7 | Marchisio (Italy) | Affordable fermenters for small/medium wineries | Suitable for startups and family vineyards |

| 8 | TOYO Stainless Steel (Japan) | Highly hygienic fermentation tanks | High-tech features, long-lasting build quality |

| 9 | Zambelli Enotech (Italy) | Tanks with integrated punch-down and pump-over systems | Combines automation with traditional tank engineering |

| 10 | Premier Stainless Systems (USA) | Fermenters for wine and beer industries | North American manufacturing, tailored for craft winemakers |

Pro Tip: Review the specialties and highlights of each supplier to find the best fit for your winery.

How Supplier Location Affects Wine Fermentation Tank Price

When you compare wine fermentation tank prices, you should always consider where the supplier is located. The location of the supplier can change the total cost you pay for your tank. Here are some important ways that location affects price:

- Shipping costs can rise if the supplier is far from your winery. Tanks made overseas, such as in China, often have lower base prices. However, you may pay more for shipping and import fees.

- Import duties and taxes can add to the final price. Some countries charge extra fees when you bring in large equipment like winery tanks.

- Delivery times can vary by region. Suppliers closer to you can deliver tanks faster and with fewer delays. This helps you start your wine production on time.

- Lead times and logistics depend on the region. North America, Europe, and Asia each have different shipping speeds and costs. You may wait longer for tanks from overseas.

- Warranty and service support may be easier to access if the supplier is nearby. If you need help or repairs, local suppliers can respond more quickly.

You can save money and time by choosing a supplier close to your location. If you buy from a supplier in another country, plan for extra shipping costs and possible delays. Always ask about delivery times and after-sales support before you make your decision.

Tip: Think about both the base price and the total cost, including shipping and service, when you compare suppliers.

Tips for Smart Buyers: Getting the Best Wine Fermentation Tank Price

How to Compare Wine Fermentation Tank Quotes Effectively

When you compare quotes for wine fermentation tanks, you should look beyond the price tag. Start by checking what each quote includes. Some suppliers add features like cooling jackets or variable lids, while others offer only the basic tank. Make a list of the features you need. Ask each supplier to include these in their quote. This helps you compare tanks with the same features.

You should also check the material and thickness of the tank. Stainless steel tanks with higher grades and thicker walls last longer. Ask about delivery times and shipping costs. Some suppliers include shipping in the price, but others do not. Always ask for a detailed breakdown so you know what you are paying for.

Tip: Create a simple table to compare quotes side by side. This makes it easier to spot differences in features, materials, and services.

What to Look for in Warranties and After-Sales Support

A good warranty protects your investment. Look for suppliers who offer comprehensive warranties on their tanks. For example, some companies provide a 3-year warranty on tanks and core parts, while others offer up to 5 years for stainless steel tanks. A strong warranty shows the supplier trusts their product.

After-sales support matters, too. You want a supplier who helps with installation, setup, and training. Some companies offer on-site support, technical training, and even free parts replacement during the warranty period. Good customer support before and after your purchase makes a big difference if you need help or repairs.

- Check for:

- Length and coverage of the warranty

- Maintenance and repair options

- Technical support and training

- Fast response to problems

Balancing Cost, Quality, and Long-Term Value in Wine Fermentation Tanks

You might see a low wine fermentation tank price and feel tempted to buy right away. However, you should think about the long-term value. Stainless steel tanks cost more at first, but they last over 30 years with proper care. Oak barrels need replacing every few years, which adds up over time. Stainless steel tanks also save you money on cleaning and reduce wine loss because they are airtight and easy to maintain.

| Factor | Oak Barrels | Stainless Steel Tanks |

|---|---|---|

| Initial Cost | $900 – $2,000 | Around $900 |

| Lifespan | Up to 8 fills | Over 30 years |

| Replacement Cost (30 yrs) | At least $4,500 | Minimal to none |

| Wine Loss (Evaporation) | Up to 6 gal/year | Negligible |

| Maintenance | Labor-intensive | Easy, less labor |

Choosing a tank with a higher upfront cost but better durability can save you money in the long run. Always balance cost, quality, and long-term benefits when making your decision.

Choosing the Right Wine Fermentation Tank for Your Needs

Matching Wine Fermentation Tank Size to Production Goals

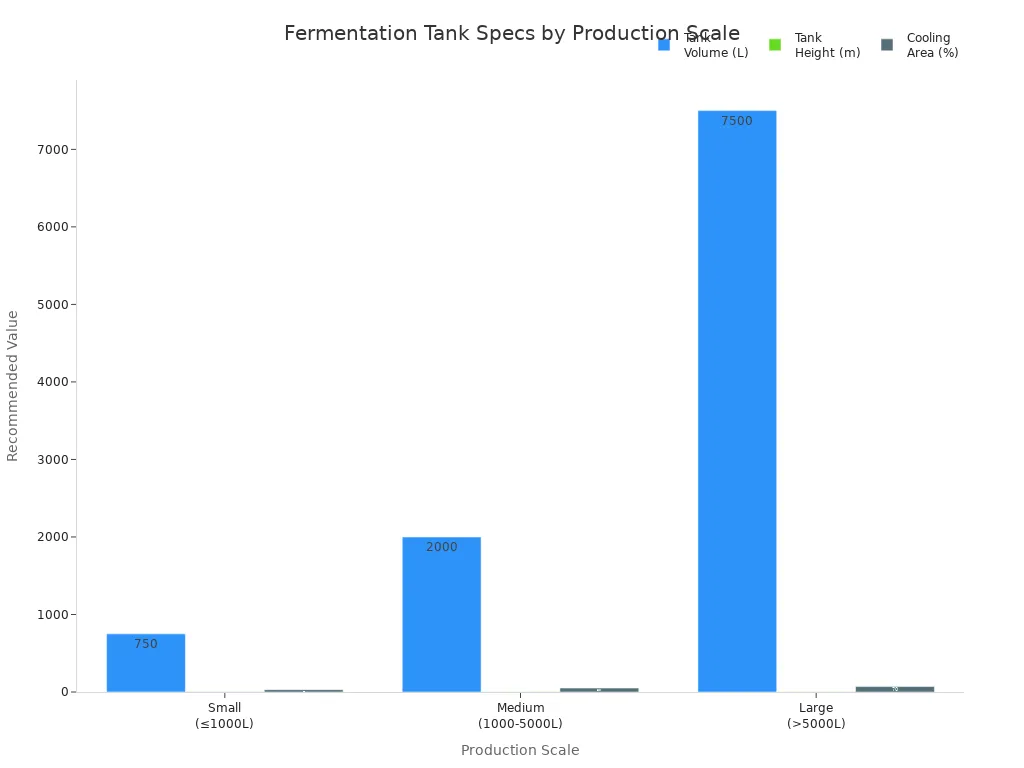

You should always match your tank size to your winery’s annual output and batch size. Start by looking at how much wine you plan to make each year. Small wineries making up to 1,000 liters each year do well with tanks between 500 and 1,000 liters. Medium producers who make 1,000 to 5,000 liters should use tanks from 1,000 to 3,000 liters. Large wineries making over 5,000 liters need tanks from 5,000 to 10,000 liters. The right tank height and cooling area also help keep your wine at the best temperature.

| Producer Size | Annual Output (L) | Recommended Tank Size (L) | Tank Height (m) | Cooling Area Coverage |

|---|---|---|---|---|

| Small | Up to 1,000 | 500 – 1,000 | 1.6 – 2.2 | ≥30% |

| Medium | 1,000 – 5,000 | 1,000 – 3,000 | 2.0 – 3.0 | ≥50% |

| Large | Over 5,000 | 5,000 – 10,000 | 3.0 – 4.5 | ≥70% |

Plan for a little extra capacity. This helps you handle special projects or growth. You should also think about the tank bottom design. Cone bottoms with the right angle and height make it easier to remove sediment and keep your wine clear.

Prioritizing Features Within Your Wine Fermentation Tank Budget

You want to get the most value from your budget. Focus on features that help you make better wine and save time. Tanks with cooling jackets let you control temperature. Adjustable lids help you work with different batch sizes. Easy-to-clean designs keep your wine safe from contamination. If you make white wines, stainless steel tanks work well for keeping flavors crisp. For red wines, you might want tanks that help with mixing and cap management.

Tip: Always leave 20–25% headspace in your tank. This space gives room for foam and expansion during fermentation.

Think about your workflow. Tanks with wide openings and sloped bottoms make cleaning faster. Modular or stackable tanks help you use your space better and allow for future growth.

When to Consider Upgrading or Customizing Your Wine Fermentation Tank

You should think about upgrading or customizing your tank when your production changes or you want better control. Here are some key points to consider:

- Match tank size to your production volume to avoid wasted space or overflow.

- Leave enough headspace for safe fermentation.

- Choose tank material based on the wine style you want to produce.

- Plan your winery layout with modular or stackable tanks for easy expansion.

- Balance your initial investment with long-term maintenance and energy costs.

- Look for features like cooling jackets, adjustable lids, and easy cleaning.

- Use scalable tank designs to support gradual growth.

- Make sure your tank supports your workflow, including sediment removal and temperature control.

- Select tanks that meet industry standards and come from reliable suppliers.

Customizing your wine fermentation tank can help you improve efficiency and quality as your winery grows.

You now know the typical price ranges for wine fermentation tanks and the main factors that affect cost.

- Entry-level tanks start around $1,500.

- Mid-range tanks reach up to $30,000.

- High-end or custom tanks can exceed $45,000.

Smart buyers compare features, materials, and supplier support before making a decision.

Take time to list your needs. Request quotes from trusted suppliers to find the best value for your winery.

FAQ

What is the best material for a wine fermentation tank?

You get the best durability and cleanliness with stainless steel. It resists rust and is easy to clean. Many winemakers choose stainless steel for its long life and neutral flavor impact.

How do I choose the right tank size for my winery?

Start by looking at your yearly wine production. Small wineries often use 500–1,000 liter tanks. Medium wineries use 1,000–3,000 liters. Large wineries need 5,000 liters or more.

Do special features like cooling jackets increase the price?

Yes, special features such as cooling jackets, variable lids, or automation add to the cost. These features help you control fermentation better and improve wine quality.

Can I customize a wine fermentation tank?

You can customize tanks for size, shape, and features. Custom tanks fit your space and production needs. Customization usually increases the price.

How long does a stainless steel wine fermentation tank last?

A well-maintained stainless steel tank can last over 30 years. Regular cleaning and care help you get the most value from your investment.