Wine fermentation tank price gives you a clear signal about both quality and function. When you select a wine fermentation tank, you see that material, capacity, tank type, features, certifications, and manufacturer reputation all shape the final price and cost. Stainless steel tanks, for example, have a higher price because they offer top durability, corrosion resistance, and temperature control. Oak or concrete tanks add to the cost due to their unique features and material requirements, while plastic tanks keep cost low but sacrifice durability and features.

| Factor | Impact on Price and Explanation |

|---|---|

| Material | Stainless steel tanks have higher upfront costs due to durability, corrosion resistance, and temperature control. Oak barrels add cost due to wood and craftsmanship. Plastic tanks are cheapest but less durable. Concrete tanks are mid-range in price and durability. |

| Capacity | Larger tanks require more materials and complex design, increasing cost. Small tanks cost less but may not meet production needs. |

| Tank Type | Open-top tanks are simpler and cheaper. Closed tanks cost more for better fermentation control. Jacketed tanks add cost due to cooling jackets. Variable capacity tanks with floating lids cost more for flexibility. |

| Features | Special features like high-grade stainless steel (304 or 316L), cooling jackets, airtight lids, conical bottoms, insulation, and mobility options increase price by adding complexity and materials. |

| Certifications | Compliance certifications (e.g., CE) raise prices due to meeting regulatory standards and quality assurance. |

| Manufacturer Reputation | Well-known brands and tanks made in technologically advanced regions (USA, Germany) cost more due to quality standards and support. Tanks from other regions (e.g., China) may offer better value but vary in price and quality. |

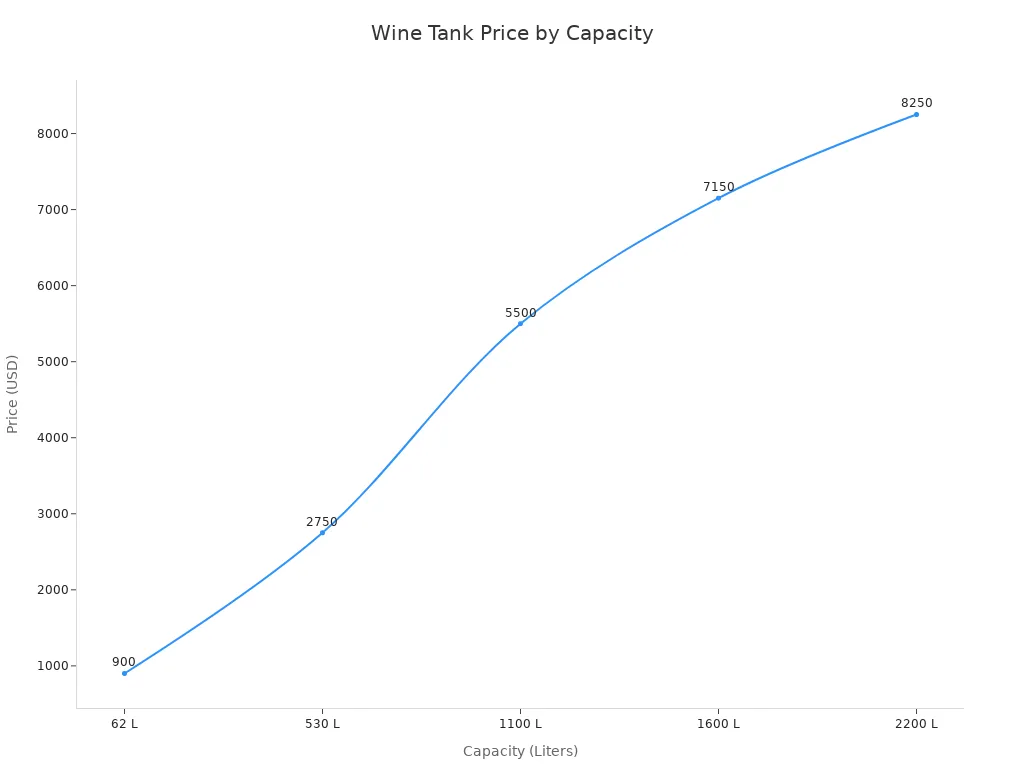

You notice that as you add advanced features—like temperature control, automation, or custom lids—the price and cost of your wine fermentation tank rise. Larger tanks cost more because they use more material and advanced features. This chart shows how price increases with capacity:

Choosing the right wine fermentation tank means you must balance price, cost, and the features that match your winemaking goals. Manufacturer reputation and certifications also play a big role in the final price, often reflecting the level of technical support and long-term value you receive.

Material and Build

Stainless Steel Tanks

When you choose a wine fermentation tank, stainless steel stands out as the industry standard. You benefit from its high durability, corrosion resistance, and long lifespan. Most professional wineries select food-grade stainless steel because it does not react with wine or impart unwanted flavors. Cleaning and sanitizing these tanks is simple, which helps you maintain strict hygiene standards and reduce contamination risks.

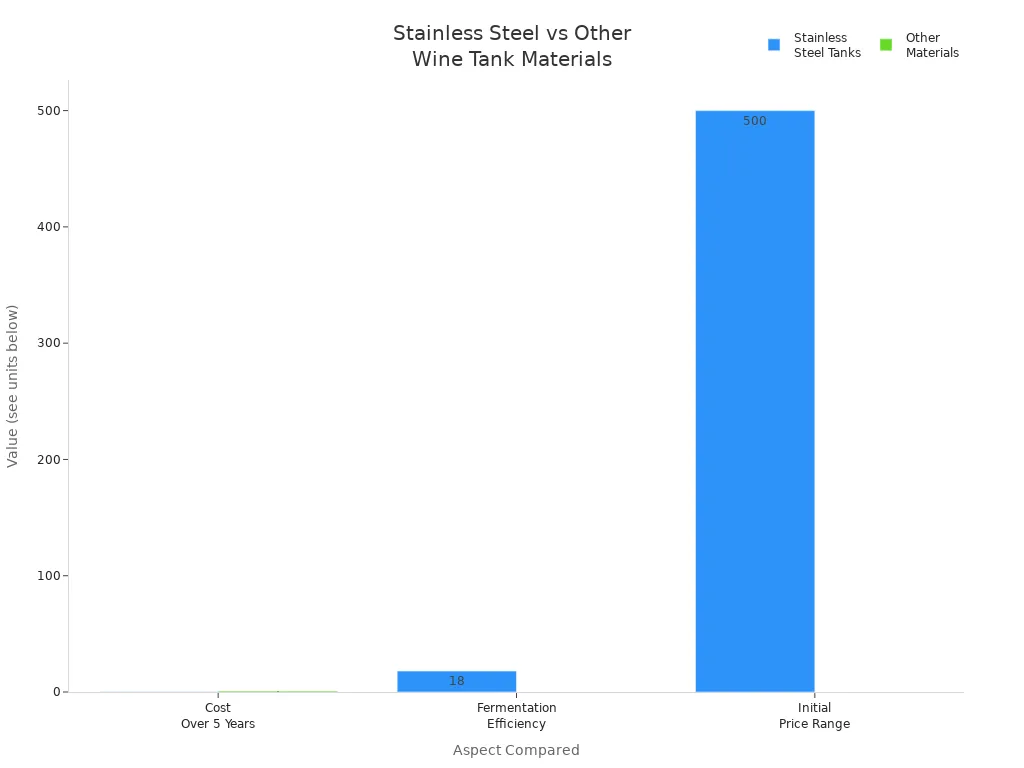

| Aspect | Stainless Steel Tanks | Other Materials (Plastic, Older Tanks) |

|---|---|---|

| Oxygen Exposure | Prevented by floating lid systems, preserving wine taste and shelf life | Oxygen ingress allowed, causing inconsistent and inferior wine quality |

| Durability | Lasts 20+ years with proper care, resistant to rust and damage | Requires frequent replacement, less durable |

| Cost Over 5 Years | Approx. $0.12 per liter (long-term cost-effective) | Approx. $0.80 per liter (higher due to replacements) |

| Fermentation Efficiency | 18% faster cycles, 30% fewer defects, $7,200 annual savings in case studies | Slower fermentation, more defects, higher costs |

| Hygiene and Cleaning | Professional-grade hygiene, easy to clean, reduces contamination risk | Harder to clean, higher contamination risk |

| Initial Price Range | $500-$1,200 (home use), $2,800-$6,500 (commercial) | Generally cheaper upfront but less durable |

| Multi-Purpose Use | Suitable for wine, beer, kombucha, cold brew coffee | Limited or less versatile |

You see that wine fermentation tanks made from stainless steel offer a cost-effective solution over time. The initial investment may be higher, but you save money through fewer replacements and lower maintenance. Stainless steel tanks also support faster fermentation cycles and fewer defects, which means higher quality wine and greater efficiency.

Other Materials

You can find wine fermentation tank options in wood, concrete, and plastic. Each material brings unique benefits and challenges.

| Material | Durability & Longevity | Additional Notes |

|---|---|---|

| Stainless Steel | Highly durable, corrosion-resistant, can last for decades | Easy to clean, does not impart flavors, cost-effective over time, customizable design |

| Wood (Oak) | Shorter effective sensory lifespan (2-3 years) | Influences flavor and texture, requires more maintenance |

| Concrete | Risk of cracking due to temperature changes | Allows oxygen permeability, sanitation challenges |

| Amphorae (Clay) | Traditional, labor-intensive | Rarely used today |

| Plastic | Cost-efficient, space-saving | Earlier concerns about odors and quality mitigated by modern polyethylene tanks |

- Wood tanks add complexity and flavor to your wine, but they require frequent cleaning and have a shorter useful life.

- Concrete tanks help regulate temperature and allow micro-oxygenation, which can soften tannins and improve texture. You must seal and maintain them well to prevent contamination.

- Plastic tanks are affordable and lightweight. They work well for small batches or experimental wines, but they do not last as long and may degrade over time.

Tip: When you select a wine fermentation tank, match the material to your production goals, budget, and desired wine style. Stainless steel remains the top choice for most wineries due to its reliability and long-term value.

Wine Fermentation Tank Price Range

When you explore the wine fermentation tank price range, you see a wide spectrum. The price can start as low as $120 for basic models and reach over $45,000 for advanced, custom-engineered tanks. The cost depends on the tank’s size, features, and level of customization. Understanding these differences helps you make a smart investment for your winery.

Entry-Level Tanks

Entry-level wine fermentation tanks offer an affordable way to start or expand small-batch winemaking. You find these tanks in several price brackets, from under $100 up to about $800. The most common price range for these tanks falls between $150 and $700. Here are some real-world examples and features you can expect:

- A 3.5-gallon stainless steel brew bucket costs about $150.

- A 304 stainless steel flexible fermenter is available for $290.

- An upgraded fermenter with a tri-clamp butterfly valve and pressure-capable lid is priced at $450.

- A professional conical fermenter starts at $660.

Typical features at this level include 304 stainless steel construction, stackable designs, tri-clamp racking arms, butterfly valves, and pressure-capable lids. Most entry-level tanks support small batch fermentation, with capacities ranging from 3.5 gallons up to 60 gallons. You often get sealed tops and flat bottoms, which help maintain wine quality and simplify cleaning.

Note: Entry-level tanks work best for home winemakers or small-scale operations. They provide essential features at a low cost, but may not offer advanced temperature control or automation.

Mid-Range Options

Mid-range wine fermentation tanks bridge the gap between basic and premium models. You usually see prices from $1,000 to $5,000. These tanks deliver higher durability and more advanced features than entry-level options. Most mid-range tanks use stainless steel and offer capacities suitable for small to medium wineries.

| Category | Price Range (USD) | Durability | Common Features |

|---|---|---|---|

| Entry-Level | Under $100-$800 | Low | Basic plastic or small stainless tanks, minimal features |

| Mid-Range | $1,000-$5,000 | High | 5-barrel stainless tanks, cooling jackets, cone bottoms, CIP systems |

| Premium | $10,000-$30,000+ | Very High | Large tanks, advanced automation, remote monitoring |

In this price segment, you gain access to features like cooling jackets for precise temperature control, cone bottoms for easy sediment removal, and clean-in-place (CIP) systems for efficient cleaning. These features improve fermentation control and wine quality. You also notice that tanks in this range often come from reputable brands, offering better support and longer warranties.

The price per gallon drops as you move to larger tanks in this category, making them cost-effective for growing wineries. For example, a 100-gallon stainless steel tank with a precision thermometer, pressure gauge, and automatic sediment drain valve costs about $2,700. This tank supports real-time monitoring and precise temperature control, which helps you produce consistent, high-quality wine.

Premium and Custom Tanks

Premium and custom wine fermentation tanks represent the top tier in both price and features. Prices start at $10,000 and can exceed $45,000, depending on size, material thickness, and the level of customization. These tanks are designed for large-scale wineries or those seeking advanced technology and unique features.

You can choose from a wide range of customizations, such as:

- Custom-designed tanks tailored to your winemaking style.

- Conical tanks for red wine fermentation, supporting advanced techniques like punch downs and pump-overs.

- Automatic pump-over solutions with proprietary seed screens.

- Custom top manway sizes (24″, 30″, 36″) for easy access.

- Multi-zone heating and cooling jackets for precise temperature control.

- Insulated versions that reduce energy costs and enhance cellar aesthetics.

- IoT sensor integration for remote monitoring and data tracking.

- Personalized branding and color options.

| Model Type | Capacity Range (L) | Material Thickness (mm) | Pressure Rating (MPa) | Price Starting Point (USD) | Unique Features and Customizations |

|---|---|---|---|---|---|

| Base Model | 800 – 3,000 | 3.0 | 1.0 | N/A | Modular design, optional viewing window (+$500) |

| Advanced Model | 3,500 – 10,000 | 4.5 | 1.5 | N/A | Viewing window, enhanced durability |

| Pro Model | 12,000 – 20,000 | 6.0 | 2.0 | Starting at $3,600 | Dual-pane viewing window, IoT sensors, 316L stainless steel, multi-zone heating/cooling, conical bottom, automatic pump-over, branding |

Premium tanks justify their higher cost with features that improve durability, fermentation precision, hygiene, and energy efficiency. For example, a large stainless steel tank with advanced temperature control, automation, and remote monitoring can cost over $30,000. These tanks often become the centerpiece of a winery’s fermentation cellar, offering both functional and aesthetic value.

Tip: Investing in premium or custom wine fermentation tanks can save you money in the long run. Advanced features reduce maintenance costs and improve wine quality, supporting your business growth.

How Features, Size, and Customization Affect Price

The wine fermentation tank price depends on several key factors:

- Features: Advanced features like cooling jackets, CIP systems, and automation increase the price but improve efficiency and wine quality.

- Size: Larger tanks cost more upfront but lower the price per gallon, making them more economical for high-volume production.

- Customization: Custom tanks with unique shapes, finishes, or branded elements command higher prices. These options let you match the tank to your specific winemaking process and brand image.

Brand reputation also plays a role. For example, Chenma offers competitive pricing with custom solutions and professional quality. Other brands like Speidel and Letina provide premium or flexible options, each with different features and support levels. Real-world examples show that investing in advanced features can save you thousands in long-term costs, thanks to improved efficiency and reduced maintenance.

When you compare wine fermentation tanks, always consider the total cost of ownership. Higher upfront prices often mean better durability, more features, and lower maintenance costs over time. This approach helps you maximize value and achieve your winemaking goals.

Capacity and Size

Small vs. Large Tanks

When you select a wine fermentation tank, you must consider how size impacts your operation. Small tanks work well for home winemakers or boutique wineries. These tanks usually cost between $100 and $500. They offer simple designs and are easy to clean. You can find features like precise temperature control and pressure regulation, which help you manage the wine fermentation process on a small scale.

Large wine fermentation tanks serve commercial and industrial wine production. The price for these tanks starts at $10,000 and can exceed $100,000. You gain advanced features such as jacketed cooling and heating, automated controls, and sediment separation. These tanks improve operational efficiency and consistency in your wine. However, you must plan for higher installation and maintenance costs.

- Small tanks:

- Lower price and initial investment

- Flexible for small-batch or experimental wine production

- Easier to move and clean

- Large tanks:

- Higher price but better suited for high-volume wine production

- Enhanced control over temperature, pressure, and pH

- Automated systems for efficient fermentation

Tip: Small tanks give you flexibility and lower costs, while large tanks deliver efficiency and consistency for bigger production goals.

Matching Production Needs

Choosing the right wine fermentation tank size means matching it to your production goals. Start by assessing your expected wine production volume. Select a tank that fits your batch size to avoid waste or excess headspace, which can cause oxidation.

Consider these factors when matching tank size to your needs:

- Measure your available space to ensure the tank fits and allows easy access.

- Prioritize temperature control features to maintain wine quality during fermentation.

- Choose tank shapes and materials that match your wine style and production process.

- Balance your budget with long-term durability and maintenance needs.

- Plan for flexibility by selecting modular tanks that support different batch sizes and future expansion.

- Look for practical features like sampling valves and easy-access manways.

- Consult with manufacturers to design custom solutions for your unique wine production requirements.

By following these steps, you ensure your wine fermentation tank supports efficient production, maintains wine quality, and adapts as your business grows. The right tank size and features help you control the wine fermentation process, manage costs, and achieve your production targets.

Tank Types and Features

Open vs. Closed Tanks

When you choose a wine fermentation tank, you must decide between open and closed designs. Open-top tanks, often made from wood or ceramic, allow air to interact with the wine during fermentation. This exposure encourages unique flavors and supports spontaneous fermentation, but it also increases the risk of contamination. Open tanks usually have a lower price, but you need to monitor the process closely to avoid spoilage.

Closed tanks, usually stainless steel or concrete, seal the wine from outside air. You gain precise control over temperature and pressure, which helps you produce consistent results. These tanks support high hygiene standards and make cleaning easier. The price for closed tanks is higher, but you benefit from better quality control and scalability. Many commercial wineries prefer closed tanks for white wine production because they preserve freshness and acidity.

| Aspect | Stainless Steel (Closed Tanks) | Oak/Wooden (Open Tanks) |

|---|---|---|

| Quality Control | Airtight, easy to clean, consistent fermentation | Unique flavors, more maintenance |

| Flavor Impact | Preserves grape flavors | Adds vanilla, spice, tannins |

| Price | Higher upfront, lower long-term | Lower upfront, higher upkeep |

| Scalability | Ideal for large wineries | Best for small batches |

Note: Open tanks offer traditional appeal and flavor complexity, while closed tanks deliver control and efficiency.

Temperature Control

Temperature control stands out as one of the most important features in a wine fermentation tank. Tanks with cooling jackets or built-in temperature systems help you keep the fermentation within the ideal range. This control improves wine quality, flavor stability, and consistency. You find that tanks with advanced temperature control often have a higher price, sometimes starting above $1,000.

- Tanks with temperature control use sensors and cooling or heating devices.

- These features help you manage yeast activity and fermentation speed.

- Small and medium wineries rely on these systems to improve batch quality.

- Home winemakers also benefit from easier monitoring and better results.

Modern wine fermentation tanks with temperature control outperform traditional tanks by stabilizing the process and reducing the risk of off-flavors. The price reflects the value of these features, as they directly impact the final product.

Accessories and Fittings

The right accessories and fittings add value and function to your wine fermentation tank. Essential features include tank stands, sample valves, cooling jackets, thermometers, and manways. These accessories help you sample wine, control temperature, and clean the tank efficiently. You also find fittings like tri clamp connectors, reducers, and sight glasses, which improve handling and monitoring.

- Tank stands and leveling feet ensure stability and drainage.

- Sample valves let you check wine quality during fermentation.

- Cooling jackets and thermowells provide precise temperature readings.

- Manways make cleaning and removing solids easier.

- Pump over systems help manage solids in red wine fermentation.

The price of wine fermentation tanks rises as you add more features and accessories. Many winemakers overlook these costs, but they play a key role in operational efficiency and wine quality. Suppliers offer a wide range of tanks, from $1,500 to over $100,000, depending on size, features, and included accessories.

Tip: Always consider the total price, including all features and accessories, when you invest in a wine fermentation tank. This approach ensures you get the best value for your winemaking process.

Certifications and Quality Standards

Safety and Compliance

When you invest in a wine fermentation tank, certifications and quality standards should guide your decision. These certifications guarantee that your equipment meets strict requirements for hygiene, safety, and durability. Tanks with recognized certifications often cost more, but they deliver peace of mind and long-term value.

| Certification / Quality Standard | Impact on Wine Fermentation Tanks |

|---|---|

| ISO 9001 (Quality Management System) | Ensures consistent product quality and manufacturing processes |

| ISO 14001 (Environmental Management) | Promotes environmentally responsible production |

| OHSAS 18001 (Occupational Health & Safety) | Guarantees safe working conditions during manufacturing |

| Food-Grade Product Certifications | Confirms suitability for hygienic contact with wine |

| Third-Party Inspections and Audits | Validates compliance with standards and quality assurance |

| Performance and Durability Testing | Ensures tanks withstand fermentation conditions and last long |

You see that a wine fermentation tank with these certifications, such as those from Chenma, meets international standards. Chenma holds ISO9001, ISO14001, OHSAS18001, and EU CE certifications. These standards ensure your tank is safe, reliable, and environmentally friendly. Tanks that meet these requirements usually range from $5,000 to $20,000 per set, reflecting the added value of compliance and quality assurance.

Tip: Always check for food-grade certifications and third-party audits. These steps help you avoid contamination and ensure your wine fermentation tank performs well for years.

Manufacturer Reputation

The reputation of the manufacturer plays a major role in the price and reliability of your wine fermentation tank. Well-known brands invest in advanced production methods and strict quality control. You benefit from better craftsmanship, durability, and technical support.

- Leading brands like Speidel and Albrigi are famous for their polished interiors, precise welds, and robust stainless steel construction. Their tanks often cost more, but you gain superior reliability and easier cleaning.

- Chenma stands out by offering ISO and CE-certified wine fermentation tanks, custom engineering, and strong after-sales service. You receive technical support and training, which helps you use your tank efficiently and safely.

- Premium manufacturers justify higher prices with proven performance, long-lasting materials, and dependable customer service.

When you choose a wine fermentation tank from a reputable manufacturer, you invest in quality and support. This decision reduces downtime, improves wine quality, and protects your business.

Assessing Wine Fermentation Tank Value

Balancing Price and Features

You need to look beyond the initial wine fermentation tank price to truly assess value. The right tank gives you more than just a place to ferment wine. It supports your process, protects your product, and saves you money over time. Stainless steel tanks, for example, may have a higher price at first, but their durability and low maintenance cost make them a smart investment. Oak barrels cost less upfront, but you replace them often and lose wine to evaporation. Concrete tanks offer thermal stability but require special cleaning, which adds to the cost.

| Factor | Oak Barrels | Stainless Steel Tanks |

|---|---|---|

| Initial Cost | $900 – $2,000 | Around $900 |

| Lifespan | Up to 8 fills | Over 30 years |

| Replacement Cost (30 yrs) | At least $4,500 | Minimal to none |

| Wine Loss (Evaporation) | Up to 6 gal/year | Negligible |

| Maintenance | Labor-intensive | Easy, less labor |

You should also consider features like cooling jackets, adjustable lids, and automation. These features improve wine quality and make your job easier. Tanks with IoT monitoring, such as SmartBarrel systems, give you real-time data and predictive maintenance. This technology adds value by reducing downtime and ensuring consistent results. When you compare tanks, match the features to your production goals and consider the long-term cost, not just the price tag.

Tip: Always factor in cleaning, maintenance, and wine loss when you calculate the true value of your wine fermentation tank.

Comparing Suppliers

A careful comparison of suppliers helps you get the best value for your investment. You want a supplier who offers more than just a low price. Look for strong technical support, clear warranty terms, and proven experience in wine fermentation tank manufacturing. Reliable suppliers provide certifications like ISO9001 and CE, which guarantee quality and safety.

- Check the supplier’s technical support, training, and warranty coverage.

- Compare tank materials, features, and customization options to fit your needs.

- Review certifications and compliance with industry standards.

- Assess reputation through customer reviews and references.

- Evaluate delivery times, after-sales service, and spare parts availability.

- Visit facilities or request third-party inspections for added assurance.

- Prioritize suppliers who offer strong after-sales technical service and clear warranty terms.

A structured approach ensures you do not overlook important details. Use a table or checklist to compare suppliers on tank material, features, certifications, support, and delivery time. This method helps you find the best balance of price, cost, and value for your wine fermentation tank.

Choosing the Right Wine Fermentation Tank

Production Goals

You need to define your production goals before selecting a wine fermentation tank. The purpose of the tank—whether for primary fermentation, aging, or storage—directly impacts your choice. For example, if you want to extract more flavor and manage fermentation for red wine, you may prefer a tank with open-top features and temperature control. If your goal is to preserve fresh taste in white wine, a closed stainless steel tank with precise cooling features works best.

| Consideration | Key Points & Impact on Production Goals |

|---|---|

| Purpose | Decide if the tank is for fermentation, aging, or storage. Fermentation tanks need temperature control features. Aging tanks benefit from features that promote oxidation and complexity. |

| Material | Oak adds flavor and softens tannins, but stainless steel preserves fruit taste and simplifies cleaning. Concrete offers gradual oxygen exposure. |

| Capacity | Match tank size to your wine production scale. Large wineries need bigger tanks for stable production. Small producers benefit from manageable sizes. |

| Storage Space | Ensure your facility supports the tank’s size and features. Consider portability and safety. |

| Budget | Oak barrels cost more, while stainless steel tanks offer cost-effective features for large-scale production. |

Your production goals also influence the price and cost of the tank. Stainless steel tanks provide economical solutions with customizable features, while wood or concrete tanks may increase price due to material and maintenance requirements. Always align your tank’s features with your desired wine style and production process.

Tips for Buyers

When you buy a wine fermentation tank, you want to avoid common pitfalls and maximize value. Follow these practical tips to ensure your investment supports your production and quality goals:

- Match tank size to your batch size, leaving about 25% free space to prevent overflow and protect wine flavor.

- Start with smaller tanks if you are new to wine production, then scale up as your needs grow.

- Plan for future expansion to avoid the cost of frequent replacements.

- Measure your available space to ensure the tank fits and allows for cleaning and maintenance.

- Choose tanks with versatile features like cooling jackets, sample valves, and manways to control the fermentation process and simplify cleaning.

- Prioritize high-quality materials such as stainless steel and look for certifications like ISO9001, ISO14001, OHSAS18001, and EU CE to ensure safety and reliability.

- Consult technical support teams or experienced winemakers for advice on tank profile and size.

- Evaluate the total cost of ownership, including maintenance, cleaning, and upgrades, not just the initial price.

- Inspect tanks regularly for leaks, scratches, and worn parts to avoid costly repairs and contamination.

- Store tanks properly—drained, dried, and covered—to prevent corrosion and maintain hygiene.

- Avoid choosing tanks solely based on price; focus on durability and features that match your production needs.

- Consider customization options to improve efficiency and wine quality, such as adjustable lids or temperature control systems.

- Select specialized tanks for red or white wines to address specific fermentation challenges.

- Research suppliers, compare quotes and warranties, and ensure compliance with industry standards.

Tip: Never overlook the importance of features and certifications. These factors protect your investment, improve wine quality, and reduce long-term cost.

You see that wine fermentation tank price directly reflects both quality and function. The table below highlights how price and cost relate to material, durability, and features:

| Aspect | Stainless Steel Tanks | Oak Barrels |

|---|---|---|

| Price | Higher upfront price | Expensive price |

| Cost | Low long-term cost | High replacement cost |

| Durability | Decades of use | Frequent cost |

| Functionality | Consistent quality | Complex flavor |

When you choose a tank, always compare price and cost for features like cooling jackets, size, and certifications. Stainless steel tanks may have a higher price, but their low maintenance cost and long-term value make them a smart choice. Oak barrels add to the price and cost with frequent replacement. You should check certifications to ensure your tank meets safety standards. Always balance price, cost, and your winemaking goals. Consult experts, review supplier support, and focus on value. Make your purchase with confidence and secure the best price and cost for your winery.

FAQ

What is the most durable material for wine fermentation tanks?

Stainless steel offers the highest durability. You can expect these tanks to last over 20 years with proper care. Stainless steel resists corrosion, does not react with wine, and supports strict hygiene standards.

How does tank size affect wine quality?

Tank size impacts temperature control and oxygen exposure. Small tanks let you experiment with batches. Large tanks help you maintain consistent quality in high-volume production. You should match tank size to your production goals for best results.

Why do certifications matter when buying a tank?

Certifications like ISO9001 and CE show that your tank meets international safety and quality standards. You gain peace of mind knowing your equipment is reliable, safe, and built for food-grade use.

What features should I prioritize for better fermentation control?

You should look for tanks with cooling jackets, sample valves, and airtight lids. These features help you manage temperature, monitor progress, and reduce contamination risk. Tanks with automation or IoT sensors give you even more control.

Can I customize a wine fermentation tank for my winery?

Yes, you can request custom sizes, shapes, and features. Many manufacturers, including Chenma, offer tailored solutions. You can add branded elements, special fittings, or advanced temperature control to fit your unique winemaking process.