Winemakers use several main types of wine fermentation tanks to shape the wine fermentation process and final wine style. The most common types of wine fermenters include stainless steel, concrete, wood, clay, plastic, glass, and fiberglass tanks. Stainless steel tanks lead the global market, making up over 60% of all wine storage tanks and fermenters. The type of fermenter affects temperature control, hygiene, and wine quality. For example, enclosed tanks help reduce contamination and allow for better control of the fermentation process. Manufacturers like Chenma design advanced stainless steel wine fermentation tank systems that support precise temperature management and efficient wine production.

Chenma is one of the professional stainless steel wine tank manufacturers that can provide wineries with a variety of solutions. We also provide chemical mixing tank、stainless steel oil tank, ect.

Types of Wine Fermentation Tanks

Overview

Winemakers use many types of wine fermentation tanks to create different wine styles. The choice of tank affects the taste, aroma, and quality of the wine. Each fermenter has unique features that suit specific production needs. Some tanks help control temperature, while others add flavors or allow for special processes. The right wine fermentation tank can improve hygiene and make the winemaking process more efficient.

Main Categories

The wine industry classifies tanks by material, design, and function. The main types of wine fermentation tanks include stainless steel, wood, concrete, clay, plastic, glass, fiberglass, and variable capacity tanks. Each type of fermenter offers distinct benefits for winemakers.

| Category | Subcategories / Types | Material / Design Features | Functionality / Use Case |

|---|---|---|---|

| Stainless Steel Tanks | Closed Top, Open Top (Variable Capacity) | Chemically inert, oxygen impermeable, polished interior, cooling jackets | Fermentation, aging, storage; versatile and customizable |

| Wood Tanks | Closed and Open Top | Oak staves, cylindrical shape, larger surface area | Fermentation with oak influence, economical alternative |

| Concrete Tanks | Egg-shaped, rectangular | Porous, thermal stability | Gentle micro-oxygenation, unique texture |

| Clay/Amphora Tanks | Amphora, ceramic | Porous, natural material | Traditional fermentation, subtle oxygen exposure |

| Plastic Tanks | Food-grade polyethylene | Lightweight, affordable | Small batch fermentation, easy handling |

| Glass/Fiberglass Tanks | Carboys, demijohns | Non-reactive, transparent | Home winemaking, small-scale production |

| Variable Capacity Tanks | Floating lid | Adjustable lid, minimizes oxidation | Flexible for different batch sizes |

| Specialized Tanks | Charmat, Bright Tanks | Pressurized, carbonation systems | Sparkling wine, clarification, stabilization |

Tip: Winemakers select the types of tanks based on the wine style they want to produce and the size of their operation. Micro-wineries often use tanks from 500 to 2,000 liters, while commercial wineries may need tanks up to 50,000 liters.

The types of wine fermenters also include fermenters for sugar-to-alcohol conversion, bright tanks for clarification, and aging tanks for flavor development. Charmat tanks help make sparkling wine by allowing secondary fermentation under pressure. Variable capacity tanks use floating lids to reduce oxidation and allow easy topping off between barrels.

Choosing the right wine fermentation tank shapes the final product. The types of wine tanks used in a winery can influence everything from flavor to efficiency. Each fermenter brings unique qualities to the winemaking process, making tank selection a key decision for every winemaker.

Stainless Steel Fermentation Tanks

Features

Stainless steel fermentation tanks have become the standard in many wineries. These tanks offer versatility for producing white, rosé, and fruit wines. Stainless steel tanks prevent unwanted oxygen levels from affecting the wine. Many tanks feature jacketed designs that allow precise temperature control, which is important for slow and steady fermentation. The non-porous, food-grade surface makes cleaning and sanitation easy, reducing the risk of contamination. Stainless steel tanks resist corrosion from acidic grape juice and cleaning agents. Their strength allows them to be pressurized, which helps with carbonation and safe wine transfer. Tank designs include cylindrical, conical, and unitank shapes. Conical bottoms, often angled at 60 degrees, help collect sediment and yeast for easy removal.

Chenma stands out as a leader in stainless steel wine tanks. The company uses advanced fabrication techniques and premium stainless steel grades like 304 and 316. Chenma’s tanks meet strict international standards, including ISO 9001:2015, ISO 14001, OHSAS 18001, and CE certification. These certifications ensure quality, safety, and environmental responsibility.

| Feature | Description |

|---|---|

| Durability | Long-lasting, suitable for commercial wineries |

| Cleaning | Smooth, non-porous surface for easy sanitation |

| Temperature Control | Cooling jackets or systems for precise fermentation |

| Corrosion Resistance | Withstands acidic juice and cleaning chemicals |

| Tank Designs | Cylindrical, conical, and multifunctional unitanks |

| Pressurization | Supports carbonation and safe wine transfer |

Pros & Cons

Advantages:

- Preserves the natural grape flavors without adding outside tastes

- Durable and cost-effective over time

- Airtight environment keeps wine fresh by limiting oxygen levels

- Easy to clean and maintain, supporting high hygiene standards

- Excellent temperature control for consistent fermentation

- Scalable for both small and large wineries

Disadvantages:

- Higher initial cost than some other fermenter types

- Does not add flavor complexity like oak barrels

- Less traditional appearance compared to wooden tanks

Best Uses

Stainless steel fermentation tanks work best when winemakers want to highlight the pure fruit character of the wine. These tanks are ideal for white, rosé, and sparkling wines, where freshness and clarity matter most. Wineries use stainless steel wine tanks for both fermentation and storage because they do not change the wine’s flavor. The tanks’ airtight design helps preserve acidity and freshness. Their easy cleaning and strong structure make them a top choice for commercial wineries that need reliable, efficient, and hygienic equipment.

Oak and Wooden Fermenters

Features

Oak and wooden wine tanks have played a key role in winemaking for centuries. These fermenters use natural wood, most often oak, to create unique conditions for wine fermentation. Oak barrels and oak foudres allow small amounts of oxygen to pass through their tight grain. This process, called micro-oxygenation, helps soften tannins and stabilize the color of the wine. Oak barrels also add flavors such as vanilla, caramel, coconut, and baking spices. The type of oak—American, French, Hungarian, or Slovenian—changes the flavor and tannin profile of the wine. New oak barrels give stronger flavors, while neutral barrels focus more on texture and less on taste. Oak foudres, which are large wooden wine tanks, offer gentle oxygen exposure and subtle flavor changes.

- Oak’s porous nature allows micro-oxygenation, which aids wine maturation.

- Oak barrels impart flavors like vanilla, coconut, and spices.

- Tannins from oak influence wine texture and aging.

- Different oak types and origins create unique wine profiles.

- Oak foudres and wooden wine tanks provide gentle, controlled oxygen exposure.

Pros & Cons

| Pros | Cons |

|---|---|

| Adds complexity and unique flavors to wine | Higher cost compared to some other fermenters |

| Micro-oxygenation softens tannins and stabilizes color | Can impart strong wood flavors if new or overused |

| Enhances mouthfeel and texture, especially in white wines | Cleaning and maintenance require more effort |

| Supports malolactic fermentation and sur lie aging | Limited control over temperature compared to stainless steel tanks |

| Traditional appearance and craftsmanship | Some winemakers prefer direct tannin additions over wood influence |

Note: Oak barrels and wooden fermenters can help stabilize anthocyanins and enhance mouthfeel during fermentation. However, some winemakers feel that fermenting on oak may add raw wood notes if not managed carefully.

Best Uses

Winemakers often choose oak barrels and wooden wine tanks for fermenting white wines like Chardonnay. These fermenters help develop texture and mouthfeel, especially when the wine remains on lees after fermentation. Oak’s insulating properties affect fermentation temperature, which can change the wine’s flavor and structure. Red wines such as Pinot Noir and Cabernet Sauvignon also benefit from fermentation in oak barrels or oak foudres. The wood surface helps with tannin development and mouthfeel. Barrel size and shape vary by region and wine style. Burgundy uses pièces for Pinot Noir and Chardonnay, while Bordeaux and American wineries use different barrel sizes to influence the wine’s character. Oak and wooden fermenters work best for wines that need complexity, texture, and a traditional touch.

Concrete Fermentation Vessels

Features

Concrete tanks have become popular in modern wineries for their unique impact on wine quality. These vessels provide a neutral environment that does not add flavors or aromas, allowing the grape’s true character to shine. The thermal mass of concrete tanks keeps fermentation temperatures stable, which helps yeast work steadily and prevents sudden temperature changes. Porous concrete walls allow gentle oxygen exchange, a process called micro-oxygenation. This softens tannins and improves the mouthfeel of the wine. Many concrete tanks come in egg, cube, or conical shapes. Egg-shaped concrete wine tanks create a natural circulation of the wine and lees, which adds body and complexity. Concrete tanks also last a long time and resist mold and bacteria, making them a clean choice for winemakers.

Note: Concrete wine tanks offer better thermal consistency than stainless steel or wood. The slow heating and cooling protect yeast health, especially during native fermentations.

| Characteristic | Description & Effect on Winemaking | Example/Notes |

|---|---|---|

| Thermal Consistency | Concrete’s thermal mass keeps temperatures steady, helping yeast stay active. | Supports healthy fermentation, especially with native yeast. |

| Porosity | Allows limited oxygen in, which softens tannins and keeps fruit flavors pure. | Enhances mouthfeel and freshness. |

| Shape | Egg, cube, and conical shapes help keep lees moving and improve wine structure. | Egg-shaped tanks create a vortex for natural lees stirring. |

| Durability & Sanitation | Concrete tanks last for years and are easy to keep clean. | Unlike wood, they do not harbor bacteria or mold. |

Pros & Cons

| Benefits | Drawbacks |

|---|---|

| Natural lees stirring from egg-shaped design enhances texture and complexity | Concrete tanks are heavy and fragile |

| Consistent lees movement leads to more balanced wines | Cleaning is more difficult than with stainless steel |

| Saves time by reducing manual lees stirring | High cost per vessel |

| Balanced oxygen flow keeps fruit flavors pure and adds roundness | Some winemakers remain skeptical due to limited scientific studies |

| Neutral material preserves the grape’s natural taste | |

| Thick walls provide strong thermal insulation and save energy |

Best Uses

Wineries use concrete tanks for both red and white wines. Red varietals like Syrah, Grenache, Mourvèdre, and Cabernet Sauvignon often ferment in concrete tanks to gain softer tannins and a rounder mouthfeel. White wines such as Grenache Blanc, Sauvignon Blanc, Chardonnay, and Bordeaux blends also benefit from the stable environment and gentle oxygen exposure. Many wineries, including Woodinville Custom Wines, Upchurch Vineyard, and The Walls Vineyards, use concrete wine tanks to enhance minerality, texture, and fruit purity. Some winemakers ferment in stainless steel and then age the wine in concrete tanks to combine precise temperature control with the textural benefits of concrete. Concrete tanks have become a favorite for those who want to highlight terroir and create wines with freshness, complexity, and age-worthiness.

Tip: Concrete tanks work well for winemakers who want to avoid oak flavors and focus on the grape’s natural qualities. The use of concrete wine tanks continues to grow as more wineries seek new ways to express texture and terroir.

Clay, Amphora, and Ceramic Fermenters

Features

Clay, amphora, and ceramic fermenters have a long history in winemaking. Amphora tanks, made from terracotta or ceramic, allow tiny amounts of oxygen to enter during fermentation. This process, called micro-oxygenation, helps soften tannins and gives the wine a smooth texture. Unlike oak barrels, amphora tanks do not add flavors to the wine. Instead, they preserve the natural fruit character and highlight the terroir. Ceramic materials also help keep the temperature steady, which protects the yeast and supports even fermentation. Amphora tanks come in many shapes and sizes, often handmade, and can last for decades. Winemakers often use these vessels for skin-contact wines, such as reds and orange wines, because the gentle oxygen flow supports complex aromas and balanced aging.

Note: Amphora tanks offer a unique balance of oxygen exposure and temperature control, making them popular for natural and biodynamic winemaking styles.

Pros & Cons

| Fermenter Type | Advantages | Disadvantages |

|---|---|---|

| Clay (including Amphora) | – Promotes chemically distinctive wines – Releases minerals that affect pH and acidity – Allows beneficial oxygen flow – Low risk of spoilage – Amphora shape improves wine movement | – Hard to sterilize (can use coatings) – Difficult to produce – Needs regular maintenance |

| Ceramic | – Unique chemical interactions – Supports wine character like clay | – Similar cleaning and maintenance challenges as clay |

Ceramic and clay fermenters help create wines with refined tannins and expressive aromas. However, they require careful cleaning and maintenance to prevent contamination. Amphora tanks are more challenging to produce because of their shape, but modern designs have improved sanitation and durability.

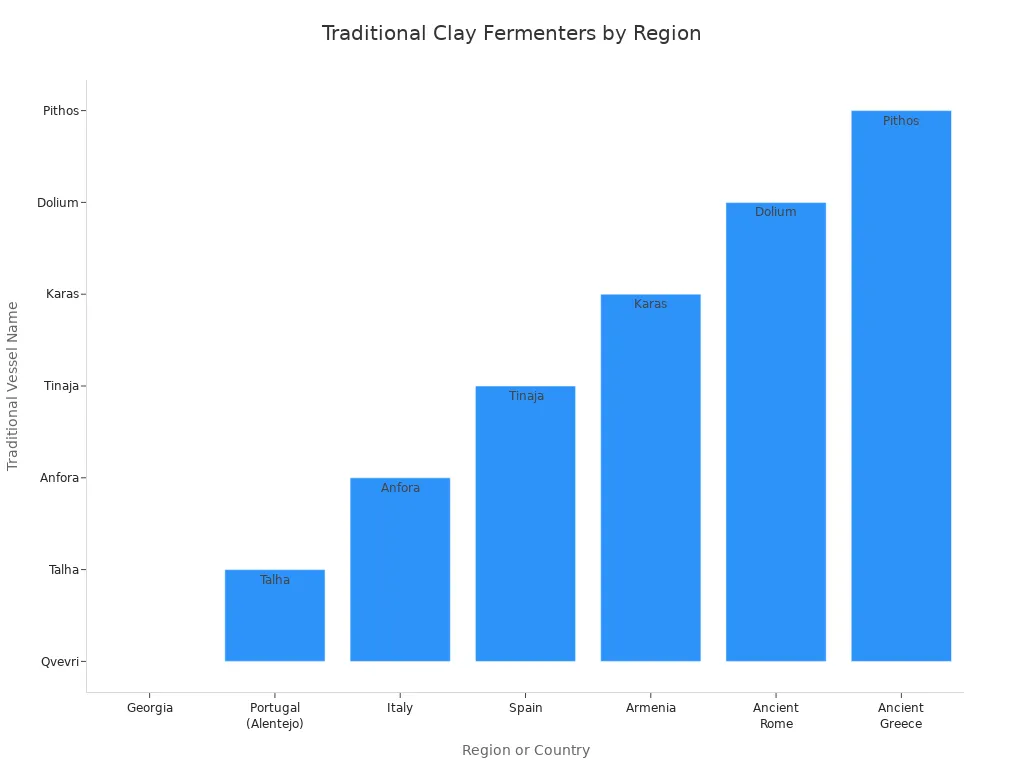

Best Uses

Winemakers use amphora tanks in many regions, especially where tradition meets innovation. Georgia uses qvevri, Portugal uses talha, and Italy uses anfora for fermenting and aging wines. These vessels often sit underground or on the cellar floor, helping control temperature. Amphora tanks work best for orange wines, reds with extended skin contact, and natural wines that need gentle oxygen exposure. The vessels support minimal intervention winemaking and help preserve freshness and texture.

Tip: Amphora tanks have seen a revival in modern wineries in Bordeaux, Champagne, Chile, and South Africa, but their deepest roots remain in the Caucasus, Iberian Peninsula, and Mediterranean.

Plastic and Polyethylene Wine Fermenters

Features

Plastic fermentation tanks, often made from high-density polyethylene (HDPE) or food-grade polypropylene, offer several practical features for winemaking. These tanks come in many sizes, making them suitable for both small and medium batches. Manufacturers design them with oversized top openings, which allow easy hand cleaning and yeast pitching. Built-in handles help users move the tanks, even when full. Many models include spigots, so winemakers can transfer wine without siphoning. The tanks resist shattering if dropped, providing extra safety in busy winery environments. Some designs feature stackable shapes, saving space in storage areas. The neutral flavor profile of polyethylene ensures that the tanks do not taint the wine, allowing winemakers to control flavors through additives or grape selection. Wide-mouth lids, sanitary sampling valves, and beveled bases for full draining add to their convenience.

Tip: Oxygen ingress through the tank walls remains low but present, so winemakers should monitor sulfur dioxide (SO₂) levels, similar to barrel aging.

Pros & Cons

Plastic fermentation tanks provide several advantages for winemakers.

- Lightweight construction makes them easy to move and handle.

- They cost less than stainless steel or glass tanks, making them ideal for beginners or small wineries.

- The tanks do not shatter like glass, reducing the risk of injury.

- Food-grade plastic ensures safe fermentation and easy cleaning.

However, these tanks also have some drawbacks.

- The material can scratch, and scratches may harbor bacteria if not cleaned carefully.

- Over time, plastic may absorb odors or flavors, which can affect future batches.

- The tanks have a shorter lifespan than glass or stainless steel options.

- They offer limited temperature control, which may not suit all wine styles.

Best Uses

Plastic fermentation tanks work best for small-scale, experimental, or budget-conscious winemaking. Many home winemakers and boutique wineries use them for testing new yeast strains or fermentation techniques. Their lightweight design allows easy movement and storage, making them practical for temporary uses such as racking or fermenting red wines. The tanks’ affordability lets producers increase capacity without large investments. However, they are not recommended for large-scale or long-term production due to lower durability and limited temperature control. When flavor neutrality and flexibility matter most, plastic fermentation tanks provide a practical solution.

| Feature/Aspect | Plastic/Polyethylene Tanks | Suitability for Winery Operations |

|---|---|---|

| Cost | Low, budget-friendly | Ideal for small-scale, experimental, or budget-conscious wineries |

| Weight and Portability | Lightweight, easy to move and store | Suitable for adaptable and temporary solutions |

| Durability | Less durable than stainless steel or concrete | Not recommended for large-scale or long-term production |

| Cleaning and Sanitation | Easy to clean if properly maintained | Practical for short-term use and experimental batches |

| Flavor Impact | Neutral, no flavor imparted | Suitable when flavor neutrality is desired |

Glass and Fiberglass Fermentation Vessels

Features

Glass fermentation vessels, such as carboys and demijohns, have a long history in small-scale winemaking. These vessels are made from thick, clear glass. Glass does not react with wine, so it keeps flavors pure and unchanged. The smooth surface of glass makes cleaning easy and helps prevent bacteria from hiding in scratches. Glass vessels come in smaller sizes, which makes them perfect for home winemakers or those making test batches. Winemakers can see the wine inside, which helps them monitor fermentation progress.

Fiberglass wine tanks are less common but have seen use in regions like the Loire Valley. These tanks are made from a polymer material reinforced with glass fibers. Fiberglass wine tanks are much lighter than glass and do not break easily. They can hold larger volumes, making them suitable for small wineries that want a lightweight option. Some winemakers choose fiberglass wine tanks for aging because they are easy to move and install.

Note: Glass vessels are completely airtight and do not let oxygen pass through. Fiberglass tanks may allow a small amount of oxygen to enter, depending on their construction.

Pros & Cons

| Aspect | Glass Fermentation Vessels | Fiberglass Wine Tanks |

|---|---|---|

| Oxygen Transfer | Impermeable, keeps wine stable | May allow slight oxygen transfer |

| Material Properties | Chemically inert, does not react with wine | Lightweight, less fragile, easy to handle |

| Durability | Heavy and fragile, can break if dropped | More durable, less risk of breakage |

| Cleaning | Smooth, easy to clean | Can scratch, which may harbor bacteria |

| Size/Capacity | Small, best for home or test batches | Larger, suitable for small wineries |

| Cost | Inexpensive for small sizes | Affordable, especially for larger volumes |

Glass vessels offer high oxygen protection and pure flavors but can break easily and are heavy to move. Fiberglass wine tanks provide a lightweight and durable alternative, though they may allow some oxygen in and can scratch over time.

Best Uses

Glass fermentation vessels work best for small batches of white or rosé wine. Their inert nature keeps flavors clean, and their size allows easy temperature control. Home winemakers often use glass carboys because they are simple and affordable. However, glass vessels are not ideal for red wine fermentation or large volumes due to their fragility and narrow openings.

Fiberglass wine tanks suit small wineries that need a lightweight, portable option for fermenting or aging wine. These tanks can handle larger volumes than glass and are easier to move around the winery. Some winemakers use fiberglass wine tanks for aging because they combine durability with ease of use. While not as common as stainless steel or glass, fiberglass wine tanks remain a practical choice for certain production needs.

Variable Capacity Wine Fermentation Tanks

Features

Variable capacity wine fermentation tanks stand out because of their floating lid system. This design lets winemakers adjust the tank’s internal volume to match any batch size. The floating lid moves up or down and seals tightly with an inflatable gasket. This airtight seal protects the wine from oxygen, which helps keep flavors fresh and prevents spoilage. Many tanks include dimple cooling jackets and temperature probes. These features give winemakers precise control over fermentation temperature. Stainless steel construction makes the tanks strong and easy to clean. Clean-In-Place (CIP) systems help with fast and thorough cleaning. These tanks also save space in the winery. One tank can handle many different batch sizes, so wineries do not need to buy several fixed capacity tanks.

Note: Variable capacity wine tanks allow quick changeovers between batches and support many wine styles. This flexibility helps wineries respond to changes in production or market demand.

Pros & Cons

Pros:

- Stainless steel construction lasts a long time and resists corrosion.

- Floating lid system reduces oxidation and fits any batch size.

- Integrated temperature control supports steady fermentation.

- Easy-to-clean surfaces and hygienic design make maintenance simple.

- Certifications like ISO 9001 and CE ensure safety and quality.

- Customization options fit different winery needs.

- Technical support and turnkey solutions help wineries grow.

Cons:

- Higher initial cost, especially for advanced or custom tanks.

- Some brands offer fewer size or feature options.

- Custom orders may take longer to deliver.

Best Uses

Variable capacity wine fermentation tanks work well for both small and large wineries. Small wineries use them to balance flexibility, durability, and cost. These tanks help with easy operation and simple cleaning. As small wineries grow, they can scale up production without buying new tanks. Large wineries choose these tanks for advanced features like temperature control and international certifications. They need reliable technical support and custom options to meet high production demands. Both small and large wineries benefit from the tanks’ ability to handle different batch sizes and wine styles. This makes variable capacity wine tanks a smart choice for many winemakers.

Fermentation Vessels Comparison

Table

| Tank Type | Cost Range | Durability | Flavor Impact | Maintenance | Best Use Cases |

|---|---|---|---|---|---|

| Stainless Steel | $1,000–$10,000 | High | Neutral (preserves grape purity) | Low | White, rosé, sparkling, large-scale |

| Oak Barrels | $500–$2,500 | Medium | Adds vanilla, spice, caramel flavors | High | Red wines, Chardonnay, aging |

| Concrete Tanks | $2,000–$15,000 | High | Adds minerality, texture | Medium | Red blends, whites, terroir-driven |

| Plastic Fermenters | $50–$500 | Low | Neutral | Medium | Small batches, home winemaking |

| Clay/Amphora | $1,000–$8,000 | Medium | Subtle oxygen, preserves fruit | High | Orange wines, natural winemaking |

| Glass/Fiberglass | $30–$1,000 | Low-Medium | Neutral | Medium | Home, test batches, small wineries |

| Variable Capacity | $1,500–$12,000 | High | Neutral, flexible batch sizes | Low | Flexible production, mixed wineries |

Note: Stainless steel tanks stand out for their durability and easy cleaning. Oak barrels add complex flavors but require more care. Concrete tanks offer stable temperatures and subtle texture changes. Plastic fermenters cost less but do not last as long. Clay and amphora vessels support traditional styles and gentle oxygen exposure.

Quick Reference

Winemakers choose fermentation vessels based on their goals and resources. Stainless steel tanks provide long life, easy cleaning, and pure flavors. Oak barrels add complexity and structure, making them popular for reds and some whites. Concrete tanks help create wines with texture and minerality. Plastic fermenters work best for small or experimental batches because they are affordable and easy to move. Clay and amphora vessels suit natural winemaking and traditional methods. Glass and fiberglass options fit home or test batches. Variable capacity tanks give flexibility for wineries that handle different batch sizes.

Each vessel type affects wine quality, cost, and maintenance needs. Stainless steel and concrete tanks last the longest and keep flavors clean. Oak and clay add unique flavors but need more care. Plastic and glass options work for smaller projects. The right choice depends on the wine style, production size, and budget.

Choosing the Right Wine Fermentation Tank

Wine Style

Selecting the right wine fermentation tank starts with understanding the wine style a winemaker wants to achieve. Each tank type supports different characteristics in the final product. For example, white wine fermentation tanks help preserve delicate aromas and crisp acidity. These tanks often feature closed tops and advanced temperature control to keep the fermentation process cool and steady. Red wine fermentation tanks, on the other hand, need open tops or special cap management systems. These features allow for skin contact and color extraction, which are essential for bold reds.

The table below shows important factors to consider for matching tank type to wine style:

| Factor | Explanation |

|---|---|

| Capacity and Size | Match tank size to production volume to avoid overflow or excessive empty space, which can affect wine quality. |

| Material Quality and Durability | Use high-grade stainless steel (AISI 304 or 316) for corrosion resistance, durability, and non-reactivity to preserve wine flavor. |

| Design Features and Customization | Include temperature control, cap management systems, adjustable lids, and wide openings for cleaning and fermentation efficiency. |

| Specialized Tanks for Wine Styles | Red wine tanks handle maceration and cap management; white wine tanks maintain cool, stable temperatures to preserve delicate flavors. |

| Budget and Long-Term Value | Balance upfront cost with durability and features; advanced tanks can reduce energy costs and maintenance expenses. |

| Compliance and Supplier Reliability | Ensure tanks meet industry standards and come from trusted manufacturers to guarantee quality and safety. |

Winemakers should also consider the impact of tank material. Oak barrels add complexity and soften tannins, making them popular for traditional reds. Ceramic pots and amphorae allow gentle oxygen exposure, which suits natural and orange wines. Stainless steel tanks work well for fruity, refreshing wines and large-scale production. The right choice depends on the desired wine style, flavor profile, and production goals.

Operational Needs

Operational needs play a major role in tank selection. Batch size determines the required tank capacity. Winemakers should allow 20-25% headspace in the tank to handle the foam and expansion during the fermentation process. Temperature control is another key factor. White wine fermentation tanks often include cooling jackets or temperature probes to keep the process stable. Red wine tanks may need systems for cap management and heat removal.

Cleaning and maintenance also influence the decision. Tanks with smooth, non-porous surfaces are easier to clean and sanitize. Features like sloped bottoms, spray ball mounts, and wide openings help prevent contamination and save time. Accessibility and design affect how quickly workers can clean and prepare tanks for the next batch.

The table below compares operational needs across common tank types:

| Operational Need | Stainless Steel Tanks | Oak Barrels | Concrete Tanks |

|---|---|---|---|

| Batch Size | Wide range from small (50L) to very large (50,000L+), matching production volume and headspace needs. | Smaller, used for aging rather than large batch fermentation. | Often used in large-scale operations due to high capacity. |

| Cleaning | Easy to clean due to non-porous, smooth surfaces; supports hygiene and maintenance efficiency. | Harder to clean because of porous material; requires more care to maintain hygiene. | Requires more care than stainless steel but easier than oak; cleaning considerations important. |

| Temperature Control | Excellent temperature regulation with integrated cooling jackets; critical for managing fermentation heat. | Poor temperature control; relies on external climate control. | Provides stable thermal inertia, maintaining consistent fermentation temperatures. |

Winemakers should also think about future growth. Choosing scalable tank designs and leaving space for additional tanks can help a winery expand without major changes.

Practical Tips

Industry experts recommend several practical steps for matching tank type to winemaking goals and budget:

- Assess production scale and batch size. Select tank capacity that matches winery goals and market demand.

- Choose tank material based on desired wine flavor. Use stainless steel for purity, concrete for texture, and oak for complexity.

- Consider space and layout. Plan for ambient conditions and future expansion.

- Balance budget by comparing initial investment with long-term maintenance and operating costs. Smaller tanks or financing options can help if budget is limited.

- Prioritize features such as drainage design, customization options, and ease of cleaning. These features improve efficiency and wine quality.

- Upgrade tanks with advanced monitoring and temperature control systems. Glycol cooling jackets can improve fermentation process consistency.

- Select reputable suppliers who offer good warranty and support. This ensures a smart, scalable investment.

- Plan for future growth by choosing scalable tank designs and leaving room for more tanks.

Tip: Consulting with specialized manufacturers like Chenma helps winemakers get custom solutions. Chenma enforces strict quality control and provides robust after-sales support, including 24/7 online assistance and a five-year guarantee. Their team specializes in customized solutions and turnkey services, covering everything from design and manufacturing to installation and technical training. Certifications such as ISO9001, ISO14001, OHSAS18001, and EU CE show their commitment to quality, safety, and environmental standards. Continuous technical support and expert guidance ensure optimal operation and maintenance of custom fermentation tanks.

Choosing the right tank shapes the entire fermentation process. The right decision supports wine style, operational efficiency, and long-term success.

Selecting the right wine fermentation tank shapes the quality and style of every wine. Each tank type—stainless steel, oak, concrete, clay, plastic, glass, or variable capacity—offers unique advantages and trade-offs. Winemakers must match their tank choice to their production goals and wine style. For the best results, they should assess their needs carefully. Experts at Chenma provide guidance and custom solutions, helping wineries achieve consistent, high-quality results.

FAQ

What is the most popular material for wine fermentation tanks?

Stainless steel is the most popular material. Over 60% of wineries use stainless steel tanks because they are durable, easy to clean, and allow precise temperature control. Stainless steel does not change the wine’s flavor.

Why do some winemakers choose oak or wooden fermenters?

Oak and wooden fermenters add flavors like vanilla and spice to wine. They also allow small amounts of oxygen to enter, which softens tannins and improves texture. Many traditional red wines use oak for these reasons.

How does tank shape affect wine fermentation?

Tank shape changes how wine and yeast move during fermentation. Egg-shaped and conical tanks help mix the wine naturally. This movement can improve texture and flavor. Flat-bottom tanks are easier to clean but may not mix as well.

Can small wineries use the same tanks as large wineries?

Yes, small wineries can use the same types of tanks, such as stainless steel or variable capacity tanks. They often choose smaller sizes to match their production needs. Many manufacturers offer custom solutions for any winery size.

How do winemakers keep tanks clean and safe?

Winemakers use cleaning systems like spray balls and smooth surfaces to remove residue. Stainless steel tanks are easiest to sanitize. Regular cleaning prevents bacteria and keeps wine quality high.

Tip: Always follow the manufacturer’s cleaning instructions for best results.