You see rapid growth in wine fermentation tanks stainless steel, with the global market for wine fermentation equipment valued at $1.6 billion in 2025 and a 4% CAGR. Chenma stands out in this competitive landscape. The company’s national design and construction certifications, innovative engineering, and advanced manufacturing set a high standard.

| Metric | Value | Notes |

|---|---|---|

| Market Value | $1.6B | Includes all fermentation equipment types |

| CAGR | 4.0% | 2025–2035 |

| Segment Share | 35% | Tanks and fermenters, mainly stainless steel |

You receive actionable recommendations based on real user feedback and industry data.

Stainless Steel Advantages

Purity and Flavor Preservation

You want your wine to taste exactly as you intend. Stainless steel tanks help you achieve this goal by offering a neutral environment for fermentation. Unlike wood, stainless steel does not add flavors or aromas to your wine. This allows you to preserve the natural character of your grapes.

- Scientific studies show that stainless steel equipment can release small amounts of metals like chromium (Cr) and nickel (Ni) into wine, especially during long fermentation periods and under acidic conditions.

- Researchers have found higher levels of Cr and Ni in sparkling wines fermented in tanks compared to those fermented in bottles. These metals can influence wine quality, affecting oxidation, browning, haze, and even flavor development.

- High concentrations of metals such as copper, iron, nickel, and zinc may cause bitterness or a metallic taste. However, these levels remain within safe limits when you follow proper tank maintenance and cleaning protocols.

- Some experts suggest that the presence of Cr and Ni can even help authenticate wines made with stainless steel methods.

You should note that while stainless steel offers excellent control over purity, ongoing research continues to compare its impact on flavor preservation with other materials. For now, stainless steel remains the industry standard for winemakers who value consistency and control.

Durability and Safety

Stainless steel tanks offer unmatched durability and safety for your winery operations. You benefit from their excellent corrosion resistance, which protects against acidic grape juice and ensures long-term stability.

- The smooth surfaces of stainless steel tanks make cleaning and disinfection easy, helping you meet strict hygiene standards.

- High strength and pressure resistance allow these tanks to handle fermentation pressures without leaking or breaking.

- Effective sealing systems and exhaust valves prevent contamination and safely release carbon dioxide during fermentation.

- Integrated temperature control systems help you maintain optimal fermentation conditions, improving both safety and wine quality.

- With regular inspection and maintenance, you can expect your stainless steel tanks to last for many years, making them a cost-effective investment.

- Stainless steel does not react with grape juice, so you avoid unwanted chemical changes and preserve the true flavor of your wine.

By choosing stainless steel, you ensure a safe, reliable, and high-quality fermentation process for every batch.

Selection Criteria

Material Quality

You want your wine to stay pure and safe. That starts with the right material. Most wineries choose tanks made from high-grade stainless steel, such as AISI 304 or 316L. These grades resist corrosion and oxidation, even when exposed to acidic grape juice. You should look for tanks that meet strict industry standards and certifications:

- ASME Boiler and Pressure Vessel Code (for pressure-rated tanks)

- 3-A Sanitary Standards (for fittings)

- ISO 9001 Quality Management System

- FDA Food Contact Compliance

- NSF/ANSI 51 for food equipment materials

Tanks with food-grade certificates, steel thickness of at least 1.5mm, and high-quality welds give you extra peace of mind.

Temperature Control

Precise temperature control helps you create consistent, high-quality wine. Stainless steel tanks often feature built-in cooling jackets or external temperature control units. These systems let you adjust and maintain the perfect fermentation temperature. Some modern tanks use intelligent automation to monitor and regulate temperature in real time. You benefit from stable fermentation, better flavor development, and lower energy costs. Newer tanks may even use advanced heat pipe technology for even more uniform temperature control.

Cleaning and Maintenance

You need tanks that are easy to clean and maintain. Stainless steel surfaces resist stains and grime, but you must avoid harsh chemicals like bleach, which can damage the protective layer. Use soft-bristle brushes and food-grade cleaners. Regular cleaning steps include:

- Empty and rinse the tank with hot water.

- Apply mild alkaline cleaners and scrub gently.

- Rinse again, then sanitize with food-grade agents.

- Let the tank air dry and inspect for wear.

Routine inspection and careful cleaning extend your tank’s life and protect your wine.

User Ratings

User feedback helps you choose the right tank. Wineries often rate tanks based on durability, ease of cleaning, temperature control, and after-sales support. High user ratings usually go to tanks from reputable brands that offer strong warranties and responsive service.

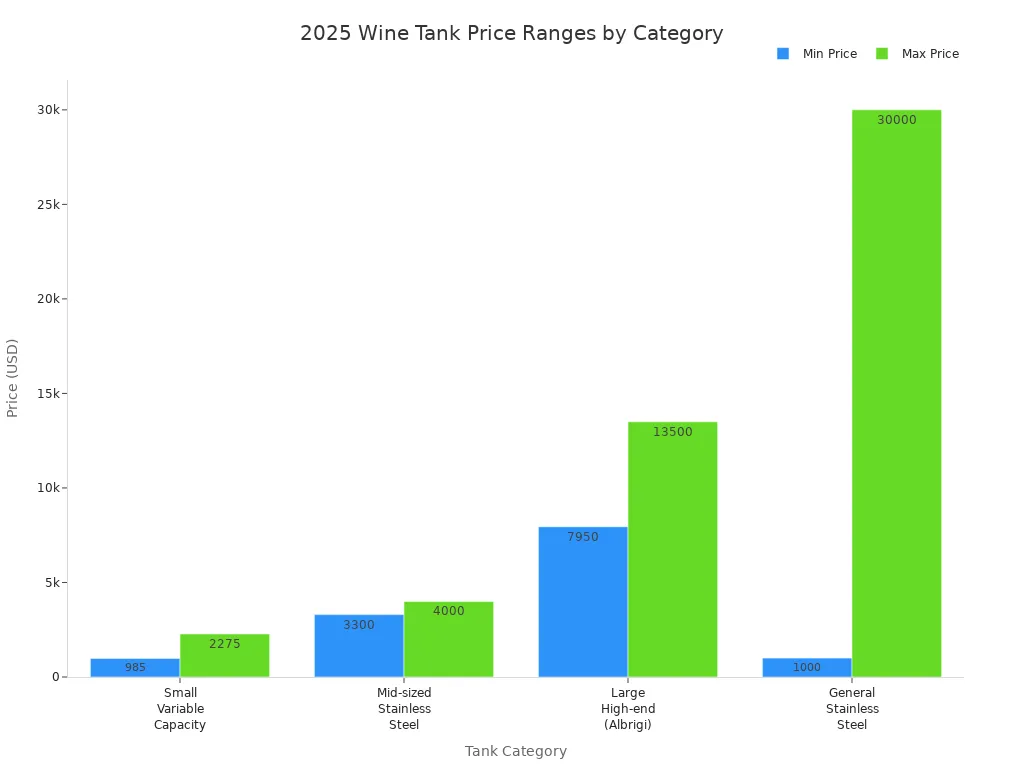

Price Range

You can find stainless steel wine fermentation tanks for almost any budget. Prices vary by size, features, and brand reputation. Here’s a quick overview:

| Tank Category / Model | Capacity Range | Price Range (USD) | Key Features / Brand Notes |

|---|---|---|---|

| Small Variable Capacity Tanks | Compact sizes | $985 – $2,275 | Optional lifting arm, suitable for small-scale use |

| Mid-sized Stainless Steel Tanks | ~1500L to 6 tons | $3,300 – $4,000 | Cooling jackets, floating lids, stackable options |

| Large High-end Tanks (e.g., Albrigi brand) | Large industrial | $7,950 – $13,500 | Polished interiors, premium manufacturer |

| General Stainless Steel Tanks | 100L – 50,000L+ | $1,000 – $30,000+ | Wide size range, advanced features, customizable |

Features like cooling jackets, floating lids, and custom designs can increase the price, but they also improve control and efficiency. Choose a tank that fits your production needs and long-term goals.

Top Brands 2025

Chenma

You want a manufacturer that delivers both quality and innovation. Chenma stands out in the wine fermentation tanks stainless steel market. The company operates a 20,000 m² facility with over 200 professionals. You benefit from their advanced engineering and custom tank solutions, designed to fit your winery’s unique needs. Chenma holds ISO9001-2005, ISO14001-2015, OHSAS18001-2007, and EU CE certifications. You can trust their tanks to meet the highest safety and environmental standards. Chenma offers turnkey projects, including process design, equipment manufacturing, installation, and technical training. You get reliable support from start to finish.

Tip: If you need a custom tank for a specific wine style or production scale, Chenma’s engineering team adapts designs to your requirements.

Speidel

You may recognize Speidel for its strong reputation in innovation and durability. Speidel offers variable capacity tanks that suit different wine styles and batch sizes. You can choose flexible solutions tailored to your winemaking process. Many winemakers prefer Speidel for its consistent quality and reliable performance.

Della Toffola

You see Della Toffola leading the way in technology and customization. Their tanks feature touch-screen controls, Wi-Fi connectivity, glycol cooling, and modular designs. You can select options that match your production goals. Della Toffola’s focus on tailored solutions helps you optimize your fermentation process.

Letina

Letina provides variable-capacity tanks known for energy efficiency and customization. You can find tanks for small or large wineries, with prices ranging from $1,500 to $15,000. Letina’s reputation for durability and innovation makes it a popular choice among winemakers who value flexibility.

Premier Stainless Systems

You want cost-effective solutions without sacrificing quality. Premier Stainless Systems offers energy-efficient, customizable tanks with modular designs. Many wineries choose Premier for its competitive pricing and reliable performance.

| Brand | Reputation and Innovation Highlights | Pricing Notes | Key Features and Tank Capacities |

|---|---|---|---|

| Chenma | Advanced engineering, certified quality, custom solutions, large-scale production | Custom pricing | Turnkey projects, custom tanks, full certifications |

| Speidel | Innovation, durability, flexible variable capacity tanks | Pricing varies | Variable capacity, tailored solutions |

| Della Toffola | Technology leader, tailored solutions, modular designs | Wide pricing range | Touch-screen, Wi-Fi, glycol cooling, modular |

| Letina | Energy efficiency, customization, durability | $1,500–$15,000 | Variable capacity, energy efficient, customizable |

| Premier Stainless Systems | Cost-effective, innovation, modular, energy efficient | Competitive pricing | Customizable, modular, energy efficient |

You can compare these brands to find the best wine fermentation tanks stainless steel for your winery. Each offers unique features and proven reliability.

Wine Fermentation Tanks Stainless Steel: Leading Models

Chenma Custom Tank

You want a tank that adapts to your winery’s unique needs. Chenma Custom Tank delivers advanced engineering and certified quality. You benefit from a design that supports efficient fermentation and easy cleaning. The tank uses stainless steel with a conical bottom, which helps you remove sediment quickly. Dual-zone cooling jackets let you control temperature with precision. Closed fermentation structures and airlock valves protect your wine from oxidation and contamination. You can monitor fermentation in real time using sampling valves and intelligent control panels.

Chenma Custom Tank includes a CIP (Clean-In-Place) system. This feature automates cleaning and reduces contamination risk. Safety valves and automation improve process control and keep your operation safe. You receive strong after-sales support and custom engineering for any production scale.

| Certification / Standard | Impact on Wine Production Quality and Safety |

|---|---|

| ISO9001 (Quality Management) | Ensures consistent manufacturing quality, leading to reliable and durable tanks. |

| ISO14001 (Environmental Management) | Supports environmentally responsible production, aligning with sustainable winemaking. |

| OHSAS18001 (Occupational Health & Safety) | Ensures safe manufacturing conditions, contributing to safer end products. |

| CE Certification | Confirms compliance with European safety and product standards, ensuring tank safety and reliability. |

Note: Tanks with these certifications help you maintain hygienic conditions and reduce contamination risk. You achieve consistent, high-quality wine with every batch.

Capacity options range from 500L to 50,000L. Pricing depends on customization, but you can expect competitive rates for advanced features. User feedback highlights Chenma’s reliability, easy maintenance, and strong support.

Speidel Variable Capacity

You need flexibility for different wine styles and batch sizes. Speidel Variable Capacity tanks offer adjustable volumes, making them ideal for small and medium wineries. You can change the tank’s capacity using a floating lid, which helps you minimize oxygen exposure and preserve wine quality. The tanks use high-grade stainless steel and feature smooth welds for easy cleaning.

Speidel tanks include cooling jackets for precise temperature control. You can add accessories like sampling valves and racking arms. Many users praise Speidel for durability and consistent performance. Capacity options range from 100L to 10,000L. Prices start around $1,000 for small tanks and reach $8,000 for larger models. Winemakers rate Speidel highly for ease of use and reliable fermentation results.

Della Toffola Closed Top

You want advanced technology and secure fermentation. Della Toffola Closed Top tanks feature touch-screen controls and Wi-Fi connectivity. You can monitor and adjust fermentation remotely. Glycol cooling jackets maintain stable temperatures, which improves yeast activity and wine flavor. The closed top design prevents contamination and oxidation.

Della Toffola tanks use modular construction. You can expand or customize your setup as your winery grows. Capacity ranges from 500L to 30,000L. Prices vary from $4,000 to $20,000, depending on features and size. Users appreciate the automation and easy integration with other winery systems. Many winemakers choose Della Toffola for high-tech solutions and reliable performance.

Letina Open Top

You want energy efficiency and easy access for manual operations. Letina Open Top tanks provide a simple design with variable capacity. The open top allows you to punch down the cap and monitor fermentation directly. Stainless steel construction ensures durability and hygiene.

Letina tanks include cooling jackets and optional floating lids. You can select capacities from 200L to 15,000L. Prices range from $1,500 to $15,000. Winemakers value Letina for flexibility and straightforward maintenance. User ratings highlight the tank’s energy efficiency and adaptability for different wine styles.

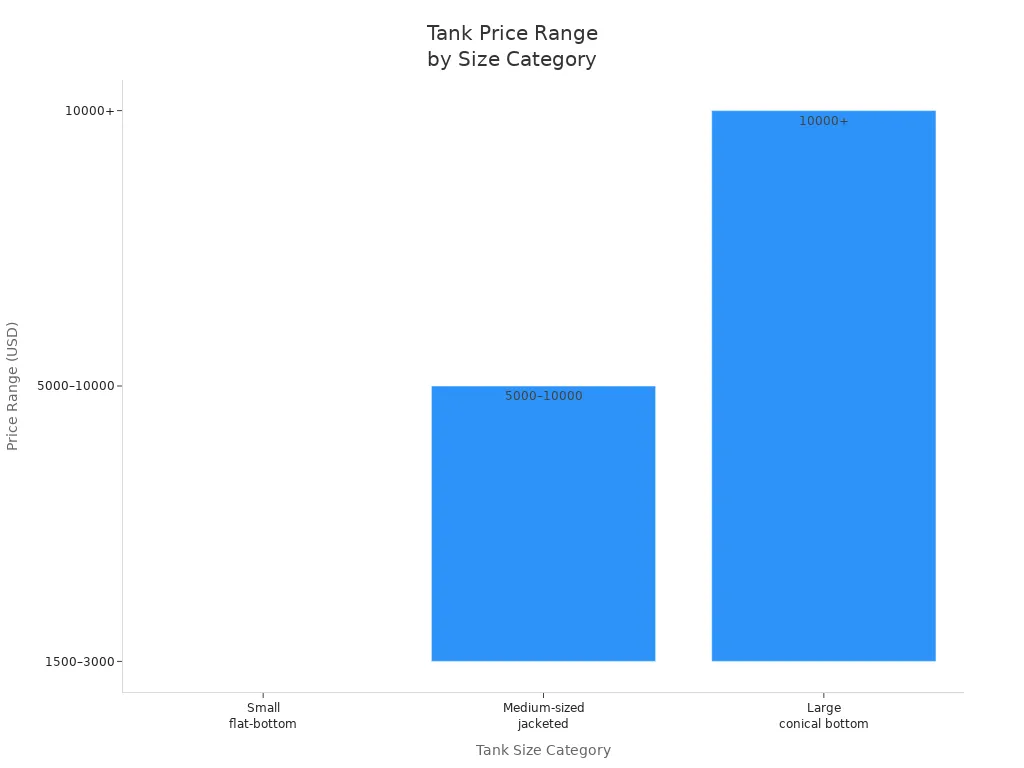

Premier Stainless Variable Lid

You need a tank that handles fluctuating volumes and small batches. Premier Stainless Variable Lid tanks offer adjustable capacity and modular design. You can choose flat-bottom or conical-bottom options. The tanks use high-grade stainless steel and feature cooling jackets for temperature control.

| Tank Size Category | Capacity Range (gallons) | Price Range (USD) |

|---|---|---|

| Small flat-bottom tanks | Under 500 | $1,500 – $3,000 |

| Medium-sized jacketed tanks | 500 – 1,000 | $5,000 – $10,000 |

| Large conical bottom tanks | Over 1,000 | $10,000+ (varies by customization) |

You can see how Premier Stainless compares to other wine fermentation tanks stainless steel in the chart below:

Premier Stainless tanks receive strong user feedback for durability and ease of cleaning. Many wineries choose these tanks for cost-effective solutions and reliable performance.

Tip: Variable lid tanks help you manage different batch sizes without risking oxidation. You save time and improve wine quality.

Comparative Data Table

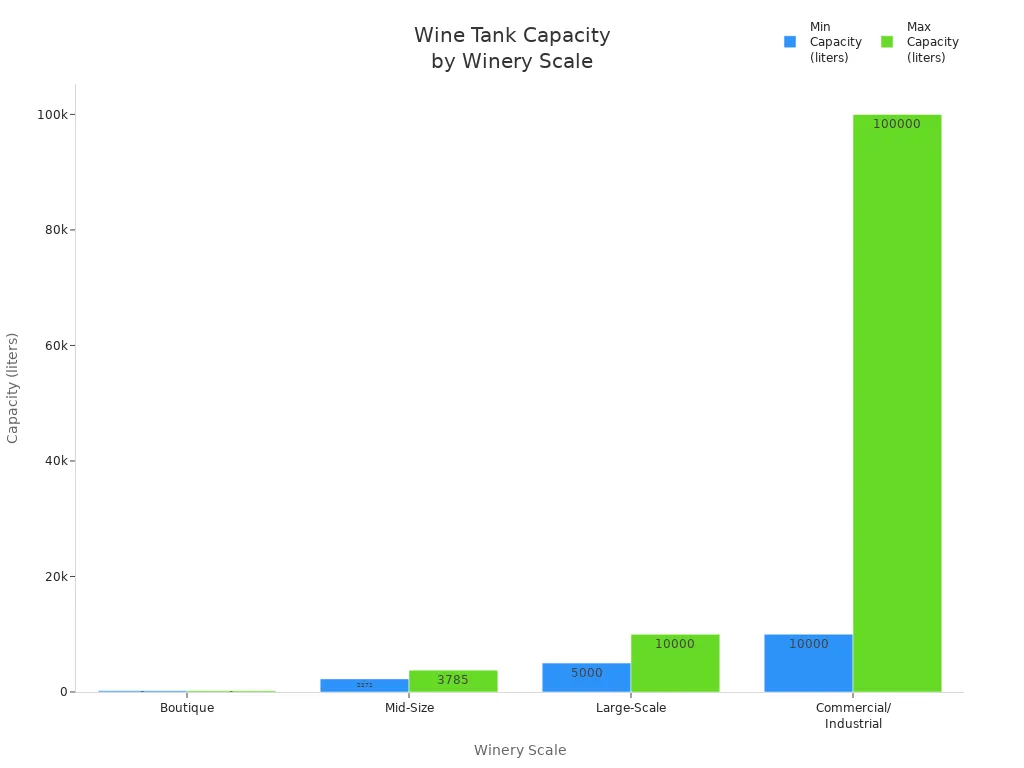

Capacity

You can choose wine fermentation tanks stainless steel with capacities that fit any winery size. Tanks range from about 227 liters (60 gallons) for boutique wineries to over 100,000 liters for commercial producers. This flexibility lets you scale your production as your business grows.

| Winery Scale | Capacity Range (liters) | Capacity Range (gallons) | Typical Use Case |

|---|---|---|---|

| Boutique | ~227 | ~60 | Small batch, pilot batches |

| Mid-Size | 2,271 – 3,785 | 600 – 1,000 | Core SKUs, estate lines |

| Large-Scale | 5,000 – 10,000+ | N/A | Bulk wine, export production |

| Commercial/Industrial | 10,000 – 100,000 | N/A | High-volume commercial production |

Material Grade

You want tanks that last and keep your wine pure. Top models use 304 or 316L stainless steel. These grades resist corrosion and do not react with acidic grape juice. You get a non-porous surface that prevents contamination and preserves natural flavors.

- 304 stainless steel offers strong corrosion resistance and durability.

- 316L stainless steel provides even better protection in demanding environments.

- Both grades support easy cleaning and long service life.

Temperature Control

You need precise temperature control for consistent wine quality. Leading tanks feature built-in cooling jackets, double walls, or insulation. These systems use circulating coolants or heating agents to keep fermentation steady.

- Cooling jackets maintain exact temperatures.

- Insulated tanks reduce temperature swings.

- Ports for temperature probes and thermowells allow real-time monitoring.

Cleaning Features

You save time and improve hygiene with advanced cleaning features. Tanks often include built-in CIP (Clean-In-Place) spray balls, conical bottoms, and side access ports.

- CIP spray balls automate internal cleaning.

- Conical bottoms help remove sediment quickly.

- Manholes and sight glasses make inspection and manual cleaning easier.

Price

You can find tanks for every budget. Prices depend on size, features, and brand.

| Tank Category / Model | Capacity Range | Price Range (USD) |

|---|---|---|

| Small Variable Capacity Tanks | Compact sizes | $985 – $2,275 |

| Mid-sized Stainless Steel | ~1,500L to 6 tons | $3,300 – $4,000 |

| Large High-end Tanks | Large industrial | $7,950 – $13,500 |

| General Stainless Steel Tanks | 100L – 50,000L+ | $1,000 – $30,000+ |

User Ratings

You want reliable feedback before you invest. Winemakers rate tanks based on durability, ease of cleaning, temperature control, and support. Top brands like Chenma, Speidel, Della Toffola, Letina, and Premier Stainless Systems receive high marks for quality and performance.

Tip: Compare user ratings and reviews to find the best fit for your winery’s needs.

Expert and User Insights

Winemaker Feedback

You see professional winemakers rely on stainless steel fermentation tanks for consistent results and long-term value. Many highlight several key advantages:

- You benefit from tanks that resist corrosion and last for years, even with frequent use.

- Cleaning becomes simple because stainless steel surfaces do not absorb flavors or odors. This helps you maintain wine purity.

- Advanced features like temperature and pressure control, insulation, and built-in cleaning systems make your fermentation process more efficient and reliable.

- Certified tanks, such as those from Chenma, meet global standards. You can trust these tanks to preserve the natural flavors of your grapes.

- Regular maintenance keeps your tanks in top condition and prevents contamination.

- You find that stainless steel tanks work well for both small boutique wineries and large commercial operations.

- Non-porous surfaces prevent unwanted flavors from affecting your wine.

- Insulation and thermal conductivity help you save energy and maintain stable fermentation conditions.

- Tanks with floating lids let you minimize oxygen exposure, which protects wine quality.

- Turnkey solutions from manufacturers simplify setup and provide technical training, so you get optimal performance from your equipment.

Tip: Many winemakers consider stainless steel tanks a smart investment for both quality and efficiency.

Industry Testimonials

You hear from industry experts that fermentation speed in stainless steel tanks can impact your winery’s workflow and wine style. Here are some insights:

- Slow fermentations in stainless steel tanks can tie up valuable tank space, making it harder for you to process new fruit during harvest.

- Fast fermentations may lead to over-extraction or loss of delicate aromas, which can reduce wine complexity.

- Slower fermentations require more attention, including frequent monitoring and sanitation, which can increase your costs.

- Some winemakers prefer slow fermentations for the unique flavors and complexity they bring, especially when using natural yeasts.

- Others choose moderately fast fermentations for greater efficiency and reliability.

- Your decision on fermentation speed often depends on grape variety and the style of wine you want to produce.

- Over many vintages, you learn that fermentation outcomes can be unpredictable, so your experience and judgment play a big role.

Note: Careful planning and monitoring help you balance tank usage, wine quality, and production efficiency in your winery.

Buying Guide

Matching Needs to Features

You want your wine fermentation tank to fit your production style and workflow. Start by considering the tank type. Closed-top tanks work well for white wines, while open-top tanks suit red wines. Variable capacity tanks help you manage different batch sizes. Cooling jackets and electronic probes allow you to control fermentation speed and flavor development. Smooth, non-porous surfaces make cleaning easier and reduce contamination risk. Customizable fittings, such as adjustable lids, sample valves, racking arms, and thermowells, improve tank adaptability. Certifications like UL 142 ensure safety and regulatory compliance. Custom fabrication lets you address specific batch sizes and space constraints, improving wine quality and operational efficiency.

| Factor | Consideration | Importance |

|---|---|---|

| Tank Type | Closed-top, open-top, variable capacity, jacketed, conical-bottom | Matches wine style and fermentation needs |

| Capacity | 50–10,000+ gallons | Aligns with production goals and workflow |

| Temperature Control | Cooling jackets, sensors | Ensures precise fermentation and wine quality |

| Material Grade | 304 or 316 stainless steel | Provides durability and corrosion resistance |

| Customization | Fittings, manways, tank shapes | Tailors tank to winemaking process |

| Maintenance & Cleaning | Smooth surfaces, easy access | Supports hygiene and reduces labor |

| Certifications | UL 142, CE, ISO | Ensures safety and compliance |

Budget Considerations

You need to match tank size to your production volume to avoid wasted space and inefficiency. Plan for extra capacity during busy harvest seasons. Compare prices based on tank size, material, and features. Stainless steel tanks have higher upfront costs, but they offer durability, flexibility, and precise temperature control. Modular or stackable tanks allow gradual expansion and better budget management. Energy-efficient and sustainable options help reduce operating costs. Automation features may increase initial costs, but they improve process control and consistency. Align your investment timing with production goals and cash flow for balanced growth.

- Match tank size to production volume

- Plan for extra capacity during harvest

- Compare prices by size, material, and features

- Consider total cost, including maintenance and long-term value

- Use modular tanks for expansion

- Factor in energy-efficient options

- Account for automation features

- Align investment with production goals

Maintenance Tips

You maximize tank lifespan by following proper maintenance routines. Clean and sanitize tanks immediately after each batch to prevent contamination. Use Clean-In-Place (CIP) procedures with recommended cleaners. Rinse thoroughly and sanitize before the next batch. Regularly inspect gaskets, valves, and cooling jackets to ensure they function properly. Keep detailed records of maintenance and cleaning activities. Train all personnel in best practices. Choose suppliers who provide technical support and spare parts. Reliable after-sales support ensures long-term performance and minimizes downtime.

Tip: Never skip cleaning cycles. Consistent maintenance protects your investment and preserves wine quality.

Recommendations by Winery Size

Small Wineries

You run a small winery. You need tanks that fit your production scale and budget. Stainless steel tanks with capacities from 15 liters to 675 liters work best for you. Speidel offers a range of flat bottom and variable volume tanks. These tanks feature laser-welded seams and cooling jackets, which help you control fermentation temperature. You get reliable performance and easy cleaning.

Here is a comparison of recommended Speidel tanks for small wineries:

| Tank Model / Type | Capacity Range | Price Range (USD) | Features & Notes | User Feedback |

|---|---|---|---|---|

| Speidel Flat Bottom Fermentation Tanks | 15L to 95L | $384.99 – $604.99 | Laser-welded, stainless steel, flat bottom | Limited reviews on 45L |

| Speidel Variable Volume Tanks | 110L to 220L | $824.99 – $1,429.99 | Laser-welded, cooling jackets, sealed tops | Some reviews on 110L |

| Speidel Larger Variable Volume Tanks | 530L to 675L | $1,999.99 – $5,169.99 | Cooling jackets, laser-welded, manway options | Few reviews noted |

| Speidel Storage Racks | N/A | $299.99 – $384.99 | Designed for flat bottom tanks | N/A |

You benefit from competitive pricing and a variety of sizes. User feedback highlights satisfaction with the 45L and 110L models. You can select tanks with cooling jackets for better temperature control. Storage racks help you organize your workspace. Speidel’s reputation for quality makes these tanks a strong choice for your small winery.

Tip: Choose variable volume tanks if you want flexibility for different batch sizes. Cooling jackets help you maintain consistent fermentation temperatures.

Large Producers

You operate a large winery. You need tanks with high capacity and advanced features. Stainless steel tanks from Chenma, Della Toffola, and Premier Stainless Systems meet your requirements. You can select tanks with capacities from 5,000 liters to over 100,000 liters. These tanks offer dual-zone cooling jackets, conical bottoms, and automated cleaning systems.

You benefit from custom engineering and turnkey solutions. Chenma provides tanks with ISO9001, ISO14001, OHSAS18001, and CE certifications. You get reliable support for installation and technical training. Della Toffola offers modular tanks with touch-screen controls and Wi-Fi connectivity. Premier Stainless Systems delivers energy-efficient tanks with modular designs.

- Choose tanks with automated temperature control for consistent wine quality.

- Select conical bottoms for easy sediment removal.

- Use CIP systems to reduce cleaning time and contamination risk.

- Request custom fittings to match your production workflow.

Note: Large producers often invest in tanks with advanced automation and monitoring systems. These features help you scale production and maintain high standards.

Hobbyists

You make wine at home or in a small community setting. You need compact, affordable tanks that are easy to use. Stainless steel tanks with capacities from 15 liters to 95 liters suit your needs. Speidel flat bottom fermentation tanks offer simple design and reliable performance. You can clean these tanks easily and store them without taking up much space.

- Select tanks with flat bottoms for easy cleaning.

- Use storage racks to organize your equipment.

- Choose models with sealed tops to reduce oxidation.

You find Speidel tanks starting at $384.99. These tanks provide durability and consistent results for hobbyists. You can experiment with small batches and enjoy the benefits of stainless steel fermentation.

Tip: Start with a smaller tank and expand as your winemaking skills grow. Stainless steel tanks help you produce clean, flavorful wine at home.

You see that wine fermentation tanks stainless steel remain the top choice for winemakers in 2025. Chenma leads with certified quality, custom engineering, and turnkey support. You benefit from tanks that offer durability, precise temperature control, and flexible capacity. If you run a large winery, choose advanced models with automation. Small producers and hobbyists gain reliability and easy cleaning.

Make your decision using real user feedback and comparative data. You secure consistent, high-quality wine production for years to come.

FAQ

What certifications should you look for in stainless steel wine fermentation tanks?

You should look for ISO9001, ISO14001, OHSAS18001, and CE certifications. These ensure your tank meets international standards for quality, safety, and environmental responsibility.

How do you clean and maintain a stainless steel fermentation tank?

You should use a Clean-In-Place (CIP) system with food-grade cleaners. Rinse with hot water, scrub gently, and sanitize. Regular inspection of valves and gaskets keeps your tank in top condition.

What size tank do you need for a small winery?

You need tanks ranging from 15 liters to 675 liters for small wineries. This size supports pilot batches and small-scale production. Variable capacity tanks offer flexibility for different wine styles.

How does temperature control improve wine quality?

Precise temperature control lets you manage fermentation speed and flavor development. Cooling jackets or electronic sensors help you keep temperatures stable, which protects your wine’s aroma and taste.

Why choose stainless steel over other materials?

Stainless steel resists corrosion, does not react with grape juice, and preserves wine purity. You benefit from easy cleaning, long lifespan, and consistent results. Most commercial wineries use stainless steel for these reasons.