You will notice clear differences between wine fermentation tanks stainless steel and oak barrels. Oak barrels add strong, astringent flavors and aromas like caramel, toffee, nuts, and vanilla. These wood-derived notes often mask the fresh fruitiness in wine. In contrast, wine fermentation tanks stainless steel keep the wine’s flavors pure, with fresher, fruitier aromas such as guava and apple. You can expect lower maintenance and longer durability with stainless steel, making them cost-effective for many parts of the winemaking process. Your choice depends on the wine style you want to create and your production needs.

Stainless Steel Tanks

Neutral Flavor

When you use stainless steel tanks for fermenting wine, you keep the natural taste of the grapes. These tanks do not add any outside flavors. Your wine will have pure fruit notes, such as apple or guava, instead of wood flavors like vanilla or caramel. This helps you create wines that taste fresh and vibrant. The chemical composition of your wine stays close to the original grape profile. Stainless steel tanks do not add tannins or phenolic compounds, so your wine remains crisp and clean. This is one of the main advantages of stainless steel tanks for wine production.

| Aspect | Stainless Steel Tanks | Oak Barrels |

|---|---|---|

| Flavor Impact | Neutral; preserves natural grape character | Adds wood-derived flavors |

| Chemical Interaction | Minimal; maintains grape profile compounds | Adds tannins and phenolics |

| Oxygen Exposure | Minimizes oxygen, preserves freshness | Allows controlled oxygen exposure |

Temperature Control

You can control the temperature very precisely with stainless steel tanks. This is important for fermenting wine because yeast needs the right temperature to work well. Stainless steel tanks can be made in any size and fitted with cooling jackets or coils. You can keep the temperature steady, which helps prevent problems like stuck fermentation. Pump-overs and cooling systems work together to keep the wine at the best temperature. This means you get consistent results every time you use your wine brewing equipment.

Tip: Precise temperature control helps you avoid oxidation and keeps your wine’s flavor profile intact.

Hygiene and Maintenance

Stainless steel tanks are easy to clean. Their smooth, non-porous surfaces do not trap residues. You can use Clean-in-Place (CIP) systems to wash the tanks without opening them. This saves you time and reduces the risk of contamination. Many tanks have sanitary manways, sample valves, and pressure relief valves for safe operation. Regular cleaning and chemical passivation protect the tank and your wine. You can trust stainless steel tanks to meet strict hygiene standards in wine making equipment.

- Stainless steel tanks resist corrosion from acidic grape juice.

- Automated cleaning systems improve efficiency and hygiene.

- Proper maintenance prevents off-flavors and contamination.

| Feature | Description |

|---|---|

| Material Grade | Food-grade stainless steel (304L or 316L) for corrosion resistance |

| Internal Surface Finish | Smooth, polished surfaces to prevent residue buildup |

| Clean-in-Place (CIP) System | Automated cleaning without manual entry |

| Hygienic Manways and Ports | Sanitary seals for easy inspection and maintenance |

Cost and Durability

You will notice that stainless steel tanks cost more at first, but they last much longer than oak barrels. A stainless steel tank can last over 30 years with proper care. Oak barrels need replacement every few years. Maintenance costs for stainless steel tanks are lower, and you spend less on energy and cleaning. This makes stainless steel tanks a smart investment for wine production.

| Cost Aspect | Stainless Steel Tank | Oak Barrel |

|---|---|---|

| Purchase Price Range | $1,000 to over $20,000 | Up to $2,000 each |

| Replacement Frequency | Lasts decades | Replace every 2-3 years |

| Maintenance & Energy | ~$200-$500/year; energy ~$300/year | Higher ongoing costs |

| Durability & Lifespan | >30 years | Shorter lifespan |

Chenma manufactures stainless steel tanks with top certifications, including ISO14001-2015, OHSAS18001-2007, and EU CE. You can request custom solutions for your wine brewing equipment needs. With over 200 professionals and advanced machinery, Chenma adapts tanks to your unique situation, ensuring safety and quality for your wine making equipment.

Oak Barrels

Flavor Enhancement

When you choose oak barrels for wine fermentation, you introduce a world of complexity to your wine. Oak adds flavour by releasing compounds like lignin and hemicellulose during oak barrel aging. These compounds break down and infuse the wine with notes of vanilla, spice, toast, and even caramel. The toasting level of the barrel changes the intensity and type of these flavours. Lighter toasts give you more vanilla and toast, while heavier toasts bring out spice, smoke, or chocolate. Oak tannins interact with the wine’s natural tannins, making the texture smoother and the mouthfeel richer. Different oak species, such as French, American, or Hungarian, each offer unique flavours. New barrels give stronger notes, while used barrels provide subtle hints. This process makes oak barrels a favorite for winemakers who want to create wines with depth and character.

- Oak barrels release flavor compounds like vanilla, spice, and toast.

- Toasting levels and oak species influence the final wine profile.

- Oak tannins soften and integrate with wine tannins, improving mouthfeel.

Oxygenation

Oak barrels allow for oxygenation, which means they let small amounts of oxygen enter the wine slowly. This slow oxygen exposure changes the wine’s color, aroma, and texture. Oxygen helps tannins and anthocyanins combine, which stabilizes color and softens the wine. The rate of oxygen transfer depends on the type of oak, the grain, and whether the barrel is new or used. American oak usually allows more oxygen in than French oak. This gradual oxygenation is essential for aging wine, as it helps develop complexity and stability. You can see richer color and smoother tannins in wines aged this way. Careful management of oxygen keeps the wine from becoming oxidized or losing its freshness.

- Oxygenation in oak barrels improves wine stability and complexity.

- Oxygen helps soften tannins and stabilize color during wine ageing.

- Barrel characteristics and wine chemistry affect oxygen transfer rates.

Oak Barrel Aging

Oak barrel aging is a flexible process. You can age wine in barrels for a few months or several years, depending on the style you want. New barrels add more flavor and tannin, which is great for bold red wines. As barrels age, they lose their ability to add strong flavors but still help with wine ageing by allowing slow oxygenation. Smaller barrels give more oak influence because of the larger contact area. Many winemakers use a mix of new and old barrels to balance oak impact and preserve delicate aromas. Properly maintained barrels last about five years before becoming neutral, but some wineries use them for over 20 years for gentle aging wine effects.

Tip: Adjust your oak barrel aging time to match your desired wine style and flavor intensity.

Maintenance Needs

Oak barrels require careful maintenance to keep them in good condition. You need to clean, rinse, and sanitize each barrel after every use. This process includes cold and hot water rinses, soda ash treatments, citric acid neutralization, and sulfur dioxide sanitization. Maintenance takes about 45-60 minutes per barrel. Annual costs depend on how many barrels you use. For example:

| Scale Level | Number of Barrels | Annual Maintenance Cost Range | Approximate Wine Volume |

|---|---|---|---|

| Hobbyist | 1-3 | $100 – $200 | 15-60 gallons |

| Serious | 4-8 | $300 – $500 | 80-160 gallons |

| Advanced | 9-15 | $600 – $1,000 | 180-300 gallons |

| Semi-Pro | 16+ | $1,000+ | 300+ gallons |

Regular maintenance extends the life of your barrels and protects your wine from spoilage. Oak barrels need more attention than stainless steel tanks, but many winemakers value the traditional appeal and the unique results they deliver.

Oak vs Stainless Steel

Flavor Impact

When you compare oak vs stainless steel, you see clear differences in how each vessel shapes the taste of your wine. Oak barrels add unique flavours to wine. You might notice hints of vanilla, spice, caramel, or even coffee. These flavours come from the wood and the toasting process. Oak also lets in a small amount of oxygen. This softens the tannins and helps the wine develop a smoother texture and deeper color. Fermenting in oak can blend these flavours more gently into the wine.

Stainless steel tanks do not add any outside flavours. You taste the pure fruit and the natural character of the grape. Stainless steel keeps the wine fresh and crisp. It also reduces oxygen contact, so your wine stays bright and lively. This makes stainless steel tanks perfect for wines where you want to highlight fruity or floral notes.

- Oak barrels add vanilla, spice, caramel, and roasted notes.

- Oak softens tannins and deepens color through gentle oxygenation.

- Stainless steel tanks keep wine fresh, crisp, and fruit-forward.

- Stainless steel preserves the original aroma and taste of the grape.

Tip: If you want a wine with more complexity and structure, choose oak. If you want a wine that tastes clean and fresh, choose stainless steel.

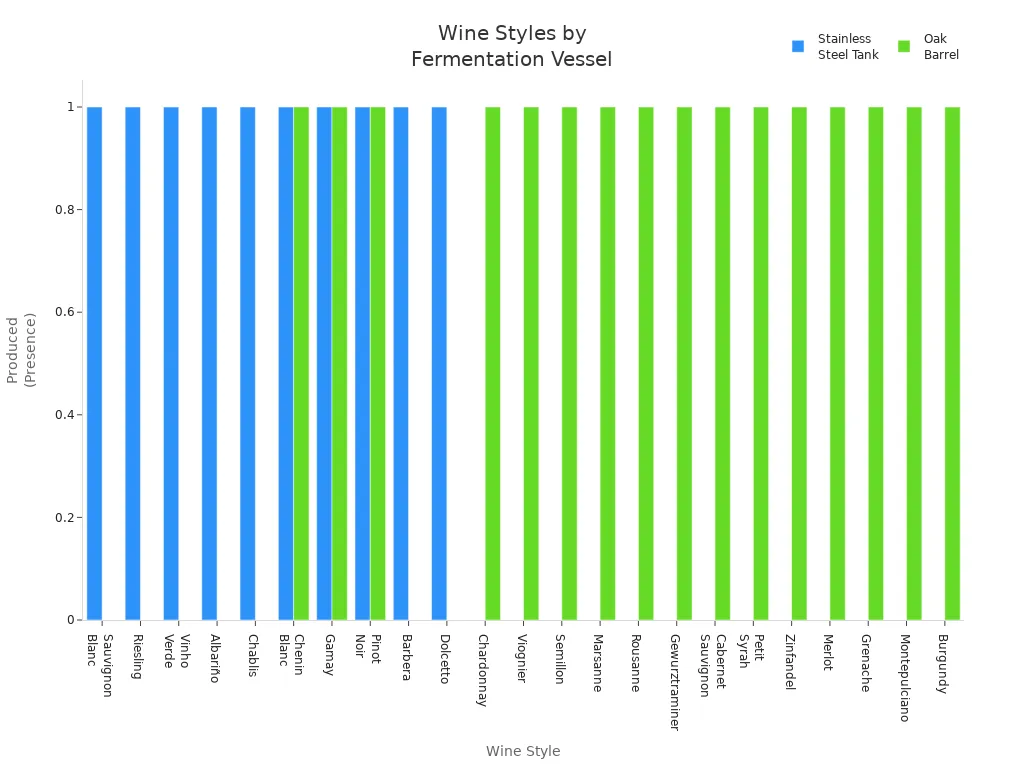

Wine Style Suitability

You need to match your fermentation vessel to the wine style you want to produce. Oak vs stainless steel each has its own strengths for different types of wine.

| Wine Style Category | Commonly Produced in Stainless Steel Tanks | Commonly Produced in Oak Barrels |

|---|---|---|

| Whites (fresh, acidic) | Sauvignon Blanc, Riesling, Vinho Verde, Albariño, Chablis, Chenin Blanc | Chardonnay, Viognier, Semillon, Chenin Blanc, Marsanne, Rousanne, Gewurztraminer |

| Reds (lighter, fresh) | Gamay, Pinot Noir, Barbera, Dolcetto | Cabernet Sauvignon, Petit Syrah, Zinfandel, Merlot, Pinot Noir, Gamay, Grenache, Montepulciano, Burgundy |

| Flavor/Effect | Preserves freshness, fruit-forward flavors, acidity; neutral flavor profile | Adds complexity, texture, vanilla, spice, creaminess; softens tannins in reds, buttery notes in whites |

You often see wines like Chablis, Prosecco, and Vermentino made in stainless steel tanks. These wines keep their bright, fruity flavors and lively acidity. Beaujolais Nouveau, a light red, also uses stainless steel to protect its delicate fruit notes.

Oak barrels work best for full-bodied reds and rich whites. Cabernet Sauvignon, Merlot, and Chardonnay often age in oak to gain complexity and a creamy texture. Oak barrels add depth and structure, making them ideal for wines that benefit from extra layers of flavor.

Note: Some winemakers use both vessels. They ferment in stainless steel for freshness, then age in oak for complexity. This hybrid approach gives you the best of both worlds.

Cost Comparison

You need to consider the pros and cons of each vessel when looking at costs. Stainless steel tanks cost more at first, but they last for decades. Oak barrels cost less to buy, but you must replace them often and spend more on maintenance.

| Factor | Oak Barrels | Stainless Steel Tanks |

|---|---|---|

| Initial Cost | $600 – $2,000 per barrel | $1,000 – $20,000 per tank |

| Lifespan | Up to 8 uses/fills | Over 30 years |

| Replacement Cost | Frequent replacements needed | Minimal to none over 10 years |

| Maintenance | High (labor-intensive) | Low (easy to clean) |

| Wine Loss (Evaporation) | Up to 6 gallons/year | Negligible |

Over a 10-year period, stainless steel tanks save you money. You spend less on replacements and maintenance. You also lose less wine to evaporation. For a mid-sized winery, stainless steel tanks offer better long-term value.

When you weigh the pros and cons, stainless steel tanks give you durability, lower costs, and easy cleaning. Oak barrels give you unique flavors and traditional appeal, but require more care and higher ongoing expenses.

Wine Fermentation Tanks Stainless Steel: What Is Better?

Decision Factors

When you decide between wine fermentation tanks stainless steel and oak barrels, you need to think about your winemaking goals, the style of wine you want, and your budget. Each vessel offers unique benefits for fermenting wine.

- Flavor Goals: If you want your wine to taste fresh and show the true character of the grape, stainless steel tanks work best. These tanks do not add extra flavors. Your wine keeps its crisp, fruity notes. Oak barrels, on the other hand, add flavors like vanilla, spice, and toast. They also soften the wine and add tannins, which can make red wines richer and more complex.

- Wine Style: Stainless steel tanks are ideal for white wines, rosé, and lighter reds. These wines benefit from a clean, pure taste. Oak barrels suit bold reds and full-bodied whites. The slow oxygen exposure in oak helps these wines develop structure and depth.

- Production Scale: If you run a large winery or want to make big batches, stainless steel tanks are more cost-effective. They come in many sizes and last for decades. Oak barrels are smaller and need more care. They fit best in small-batch or premium wine production.

- Budget: Stainless steel tanks cost more at first, but you use them for many years. Oak barrels cost less to buy, but you must replace them often. Maintenance for barrels also takes more time and money.

Tip: Think about the wine you want to create. If you want complexity and tradition, oak barrels may be right. If you want freshness and efficiency, wine fermentation tanks stainless steel offer clear advantages.

Here is a table to help you compare:

| Factor | Stainless Steel Tanks | Oak Barrels |

|---|---|---|

| Flavor Influence | Neutral, preserves grape character | Adds vanilla, spice, tannins |

| Temperature Control | Excellent, precise | Poor, needs external control |

| Oxygen Exposure | Minimal, airtight | Moderate, allows slow oxygenation |

| Cleaning | Easy, non-porous | Harder, porous, needs more care |

| Lifespan | 20+ years | 3-5 years optimal use |

| Cost | High initial, low maintenance | Moderate initial, ongoing replacement |

| Best For | Whites, rosés, fresh reds | Big reds, wines for aging |

Practical Considerations

You should also look at practical needs when choosing what is better for your winery. The right equipment can make your work easier and improve your wine quality.

- Ease of Use: Stainless steel tanks are easy to clean and maintain. Their smooth surfaces do not trap residue. You can use automated cleaning systems, which save time and reduce the risk of contamination. Oak barrels need careful cleaning and regular checks to prevent spoilage.

- Customization: Chenma offers custom stainless steel tanks for any winery size. You can choose tanks with cooling jackets, pressure controls, and special ports for sampling. Chenma’s engineers design tanks to fit your space and production needs. You get support from design to installation and training.

- Temperature Control: When fermenting wine, temperature matters. Stainless steel tanks let you control temperature with built-in cooling systems. This helps you avoid problems like stuck fermentation and keeps your wine consistent. Oak barrels do not offer this level of control.

- Durability and Longevity: Stainless steel tanks last for decades. You can use them for many cycles without losing quality. Oak barrels wear out after a few years and need replacing. This makes stainless steel a smart choice for long-term wine production.

- Scalability: If you plan to grow your winery, stainless steel tanks scale up easily. You can add larger tanks or more units as your needs change. Oak barrels require more space and labor as you expand.

Note: Chenma’s wine fermentation tanks stainless steel come with advanced features like integrated cooling, pressure regulation, and easy cleaning. You can tailor every detail to match your winemaking process.

When you ask what is better, think about your goals, the wine style you want, and your resources. Stainless steel tanks give you flexibility, purity, and efficiency. Oak barrels offer tradition and complexity. For many modern wineries, wine fermentation tanks stainless steel provide the best balance of quality, cost, and ease of use.

Durability and Lifespan

Stainless Steel Tanks

You can count on stainless steel tanks to last for decades. When you choose these tanks, you invest in equipment that often serves you for over 30 years. This long lifespan comes from the strong, corrosion-resistant material. Stainless steel tanks do not rust or break down easily, even when you use them for wine ageing year after year. You can clean them thoroughly, which helps prevent damage and keeps your wine safe. Many winemakers prefer stainless steel aging because it protects the wine and the tank itself. You will find that these tanks keep their shape and function, even after many cycles of use. With proper care, you rarely need to replace them. This makes stainless steel tanks a smart choice for anyone who wants reliable equipment for aging wine.

Stainless steel tanks offer unmatched durability. You can trust them to support your wine ageing process for generations.

Oak Barrels

Oak barrels give your wine unique flavors, but they do not last as long as stainless steel tanks. Most oak barrels stay useful for up to 8 fills, which means only a few years of wine ageing before you need to replace them. After several uses, oak barrels lose their ability to add flavor to the wine. You must buy new barrels if you want to keep getting those special oak notes. The wood in oak barrels can also wear down or develop leaks over time. You need to check and maintain each barrel carefully to avoid problems during wine ageing. Many winemakers use older barrels for gentle aging wine, but the impact on flavor drops with each use. If you want consistent results, you will need to plan for regular barrel replacement.

Oak barrels bring tradition and complexity to wine ageing, but you should expect to replace them every few years to maintain quality.

Maintenance and Cleaning

Stainless Steel Tanks

You can keep stainless steel tanks clean with a clear and effective process. These tanks have smooth, non-porous surfaces, so you can use strong cleaning agents and automated systems. Here is a step-by-step guide for cleaning:

- Remove all wine and sediment from the tank.

- Rinse the inside with hot water to wash away loose residues.

- Use an alkaline cleaner, such as sodium hydroxide, to break down organic material.

- Scrub any stubborn spots with a soft brush, but never use steel wool or abrasive pads.

- Rinse again with hot water to clear away cleaning agents.

- Apply an acid cleaner, like nitric or citric acid, to remove mineral scale and help passivate the surface.

- Sanitize the tank with a food-grade sanitizer, such as peracetic acid or iodophor, making sure all surfaces are covered.

- Let the tank air dry completely to stop bacteria from growing.

- Inspect the tank for any damage or wear, and replace small parts like gaskets if needed.

- Follow a regular cleaning schedule: rinse daily, deep clean weekly, and passivate monthly.

Tip: Always wear protective gear and make sure the area is well-ventilated when handling cleaning chemicals.

This routine helps you maintain hygiene, prevent corrosion, and protect your wine’s quality.

Oak Barrels

Oak barrels need a different approach because wood is porous and sensitive. You must use gentle methods to avoid damaging the barrel and to keep the wine safe. Cleaning usually involves manual work:

- Scrub the inside with a barrel brush, using only hot or cold water.

- Avoid harsh chemicals, as they can harm the wood and affect the wine’s flavor.

- Rinse thoroughly to remove any residue.

- Use hot water or steam for sterilization, but do not use chemical sanitizers meant for metal tanks.

- Dry the barrel completely to prevent mold and spoilage.

Here is a table comparing cleaning requirements:

| Aspect | Oak Barrels Cleaning Requirements | Stainless Steel Tanks Cleaning Requirements |

|---|---|---|

| Cleaning Method | Manual scrubbing with barrel brushes, rinsing with hot/cold water | Alkaline cleaners, foam lances, steam cleaning, high-pressure rinses |

| Use of Cleaning Agents | Avoided to protect wood; mainly water | Alkaline and acidic cleaners, chemical sanitizers |

| Equipment | Barrel cleaner, rotating nozzles, suction for water removal | Pressure cleaners, steam cleaners, automated systems |

| Cleaning Intensity | Gentle to protect wood | Aggressive cleaning possible due to durable surface |

| Hygiene and Sterilization | Hot water or steam for sterilization | Steam, hot water, and chemical sanitizers |

| Impact on Material and Wine | Methods chosen to avoid wood damage and preserve wine flavor | Focus on residue removal and tank integrity without affecting wine flavor |

You must check oak barrels often for leaks or spoilage. Regular care keeps them in good condition and helps your wine develop the right flavors.

Suitability for Wine Styles

White Wines

You often see white wines made in stainless steel tanks. These tanks help you keep the wine’s fruit flavors pure and fresh. You can control the temperature closely, which is important for fermenting wine. This control lets you protect delicate aromas like citrus, apple, and guava. Stainless steel does not add any extra flavors or tannins. You get a wine that tastes crisp and clean. Many winemakers choose stainless steel for Sauvignon Blanc, Riesling, and Albariño. Industry reports show that stainless steel tanks are easy to sanitize and cost-effective. You can rely on them for wines where you want the grape’s natural character to shine.

Tip: If you want a white wine with bright acidity and pure fruit notes, stainless steel tanks are the best choice.

| Wine Style | Preferred Vessel | Key Benefit |

|---|---|---|

| Sauvignon Blanc | Stainless Steel Tank | Preserves freshness |

| Riesling | Stainless Steel Tank | Maintains fruit character |

| Chardonnay | Oak Barrel or Stainless | Adds complexity or purity |

Red Wines

You can use both oak barrels and stainless steel tanks for fermenting wine, but each vessel gives you different results. Oak barrels change the tannin structure in red wines. The wood provides hydrolysable tannins, which are less astringent and more bitter than grape tannins. Oak barrels allow small amounts of oxygen to enter, which softens the tannins and improves mouthfeel. This process helps you create a smoother, richer wine. Barrel age, size, and toasting level all affect how much oxygen and tannin the wine gets. French oak barrels give you fine-grained tannins and subtle aromas, while American oak adds bolder flavors. Winemakers often use oak barrels for Cabernet Sauvignon, Merlot, and Pinot Noir to add complexity and stability.

Note: Oak barrels help you make red wines with deep color, smooth texture, and layered flavors.

Specialty Wines

You can make specialty wines like high-quality reds, rich whites, sparkling wines, and sweet wines in oak barrels. Oak barrels have a porous nature that allows micro-oxygenation. This softens tannins and improves texture. Oak also adds flavors like vanilla, spice, clove, and toast. These flavors make your wine more complex. French and American oak species give you different results. French oak offers subtle aromas and fine tannins. American oak provides sweeter notes like caramel and vanilla. Oak barrel fermentation also helps with malolactic fermentation, which reduces acidity and adds buttery notes. These effects create harmonious wines that are hard to match with other methods.

- Specialty wines often aged in oak barrels:

- Cabernet Sauvignon

- Chardonnay

- Sparkling wines

- Sweet wines

Callout: Oak barrels have been used for centuries to create some of the world’s finest specialty wines. Their unique impact on flavor and texture sets them apart from other vessels.

Summary Table: Oak vs Stainless Steel

When you choose between oak barrels and stainless steel tanks for wine fermentation, you need to see the differences clearly. The table below gives you a side-by-side look at the most important features. This helps you decide which vessel fits your winemaking goals best.

| Feature | Stainless Steel Tanks | Oak Barrels |

|---|---|---|

| Flavor Impact | Keeps grape flavors pure and fresh | Adds vanilla, spice, caramel, and toast notes |

| Oxygen Exposure | Minimal, keeps wine crisp | Slow oxygenation, softens tannins |

| Temperature Control | Precise, easy to adjust | Hard to control, needs extra equipment |

| Cleaning | Simple, fast, uses automated systems | Manual, time-consuming, needs special care |

| Durability | Lasts 30+ years with proper care | Lasts 3-5 years before losing flavor impact |

| Cost Over Time | High at first, low maintenance, saves money long-term | Lower at first, higher replacement and upkeep |

| Wine Styles | Best for whites, rosés, light reds | Best for bold reds, rich whites, specialty wines |

| Customization | Highly customizable (size, features, cooling) | Limited to barrel size and toast level |

| Wine Loss | Very low evaporation | Up to 6 gallons lost per year per barrel |

Tip: Use this table to match your wine style and production needs. If you want pure fruit flavors and easy cleaning, stainless steel tanks work best. If you want complex flavors and tradition, oak barrels give you that special touch.

Key Points to Remember

- Stainless steel tanks help you make fresh, fruit-forward wines. You get precise control and easy maintenance.

- Oak barrels add depth, smoothness, and unique flavors. You need to invest more time and care.

- Think about your wine style, budget, and how much work you want to do. The right choice helps you reach your winemaking goals.

:grapes: Choose the vessel that brings out the best in your wine!

You have two strong options for wine fermentation. Stainless steel tanks keep your wine fresh and pure, cost less over time, and are easy to clean. Oak barrels add flavors like vanilla and spice, and they help soften tannins in traditional reds.

- Choose stainless steel for crisp whites, light reds, and large batches.

- Pick oak barrels for complex reds and classic wine styles.

- You can mimic oak effects in stainless steel tanks with oak chips and micro-oxygenation.

Chenma offers custom stainless steel solutions with advanced features and top certifications, helping you achieve your winemaking goals with confidence.

FAQ

What is the main advantage of using stainless steel tanks for wine fermentation?

You get precise temperature control and a neutral environment. Stainless steel tanks do not add flavors to your wine. This helps you keep the grape’s natural taste and aroma. Many winemakers choose stainless steel for fresh, fruit-forward wines.

How often do you need to replace oak barrels?

You usually replace oak barrels every 3 to 5 years. After several uses, the barrel loses its ability to add flavor. New barrels give stronger oak notes. Used barrels provide only gentle aging effects.

Can you combine stainless steel and oak in winemaking?

Yes, you can. Many winemakers ferment wine in stainless steel tanks and then age it in oak barrels. This method gives you both fresh fruit flavors and added complexity from the oak.

Are stainless steel tanks easy to clean?

Yes, stainless steel tanks have smooth, non-porous surfaces. You can use automated cleaning systems. This makes cleaning fast and reduces the risk of contamination. You save time and keep your wine safe.