When it comes to crafting exceptional wine, the equipment you use matters as much as the grapes themselves. Stainless steel wine tanks have revolutionized winemaking, offering unmatched control and efficiency. These tanks are durable, easy to clean, and ideal for maintaining the integrity of your wine’s flavor.

California winemakers were among the first to embrace stainless steel fermentation tanks. Their ability to prevent bacterial spoilage and enhance white wine production made them indispensable.

From controlled fermentation to improved productivity, modern wineries rely on stainless steel tanks to meet growing production demands. With tank volumes reaching up to 2,000 liters and advanced chemical composition metrics, they ensure precision at every step.

Chenma is one of the professional stainless steel wine tank manufacturers that can provide wineries with a variety of solutions. We also provide cider fermenter、variable capacity wine tank, ect.

Variable Capacity Stainless Steel Wine Tanks

Features of Variable Capacity Tanks

Variable capacity stainless steel wine tanks are designed with flexibility in mind. These tanks come with adjustable lids that can be positioned to match the volume of wine being stored or fermented. This feature minimizes oxygen exposure, which is crucial for preserving the wine’s quality.

The tanks often include advanced technical specifications to enhance performance. For example:

- Fully variable systems allow precise control over temperature and fermentation conditions.

- Web-enabled diagnostics provide real-time monitoring and adjustments from any device.

- Variable speed compressors ensure quiet and energy-efficient operation.

These cylindrical fermenters are also built with high-quality stainless steel, ensuring durability and resistance to corrosion. Their vertical design optimizes space, making them ideal for wineries with limited floor area.

Benefits of Variable Capacity Tanks

You’ll love the flexibility these tanks offer. Whether you’re producing a small batch or a larger volume, the adjustable lid ensures consistent quality by reducing oxidation risks. This adaptability makes them a cost-effective choice for wineries of all sizes.

Here’s why they’re a game-changer:

- They optimize space usage, especially in compact wineries.

- Their long lifespan reduces the need for frequent replacements, saving you money in the long run.

- They contribute to sustainability efforts since stainless steel is recyclable.

Additionally, these tanks enhance production efficiency. By maintaining precise fermentation conditions, they help you achieve consistent results every time.

Best Use Cases for Variable Capacity Tanks

Variable capacity tanks shine in small to medium-sized wineries. If you’re experimenting with different wine styles or working with varying production volumes, these tanks are perfect. They’re also ideal for premium wine production, where controlling oxygen exposure is critical.

For wineries focused on sustainability, these tanks align with environmentally conscious practices. Their recyclability and energy-efficient features make them a smart choice. Whether you’re crafting red, white, or sparkling wines, these cylindrical fermenters deliver exceptional results.

Tip: If you’re just starting out or expanding your winery, investing in variable capacity stainless steel tanks can provide the versatility you need to grow.

Closed-Top Stainless Steel Fermentation Tanks

Features of Closed-Top Tanks

Closed-top stainless steel fermentation tanks are a staple in modern winemaking. These tanks feature a fixed, sealed top that prevents external contaminants from entering during fermentation. This design ensures a controlled environment, which is essential for producing high-quality wine.

The tanks are crafted from premium stainless steel, offering excellent durability and resistance to corrosion. Their flat-based design enhances stability, making them reliable even in challenging conditions. Research has shown that flat-based tanks outperform legged tanks during seismic events, ensuring better reliability and performance under stress. This makes them a dependable choice for wineries in earthquake-prone regions.

Another standout feature is their ability to maintain consistent temperature and concentration gradients. Advanced models often include integrated cooling jackets or temperature control systems, which help you manage fermentation conditions with precision. This is crucial for achieving uniformity in large-scale wine fermentation processes.

Benefits of Closed-Top Tanks

Closed-top tanks offer several advantages that make them a favorite among winemakers. First, their sealed design minimizes oxygen exposure, preserving the wine’s flavor and aroma. This is especially important for delicate wines like whites and rosés.

These tanks are also incredibly easy to clean and maintain. The smooth stainless steel surface resists bacterial growth, ensuring a hygienic environment for your wine. Plus, their robust construction means they can withstand years of use without showing signs of wear.

Another key benefit is their versatility. Whether you’re fermenting red, white, or specialty wines, these tanks deliver consistent results. They also support large-scale production, making them ideal for commercial wineries aiming to meet high demand without compromising quality.

Best Use Cases for Closed-Top Tanks

Closed-top stainless steel fermentation tanks excel in various winemaking scenarios. Here are some of the best use cases:

- Small-Scale Winemaking: Perfect for home winemakers and boutique wineries due to their precision and ease of cleaning.

- Large-Scale Commercial Production: Ideal for handling massive volumes while ensuring uniformity and reducing maintenance needs.

- Specialty Wines and Experimental Batches: Provide unmatched control for crafting unique flavor profiles and testing experimental techniques.

These tanks are particularly well-suited for wineries located in seismically active areas. Their flat-based design ensures stability, reducing the risk of damage during earthquakes. Whether you’re producing a few barrels or thousands of liters, closed-top tanks offer the reliability and performance you need.

Pro Tip: If you’re looking for a tank that combines durability, ease of use, and versatility, closed-top stainless steel fermentation tanks are a fantastic choice.

Conical Stainless Steel Fermentation Tanks

Features of Conical Tanks

Conical fermenters are a favorite among winemakers for their unique design and functionality. These tanks feature a cone-shaped bottom that allows sediment, yeast, and other solids to settle naturally at the base. This design makes it easy to separate the wine from unwanted particles, ensuring a cleaner final product.

Most conical stainless steel fermentation tanks come equipped with cooling jackets or integrated temperature control systems. These features help you maintain precise fermentation conditions, which is essential for producing consistent wine quality. Additionally, their closed system design prevents oxygen and contaminants from entering, preserving the wine’s flavor and aroma.

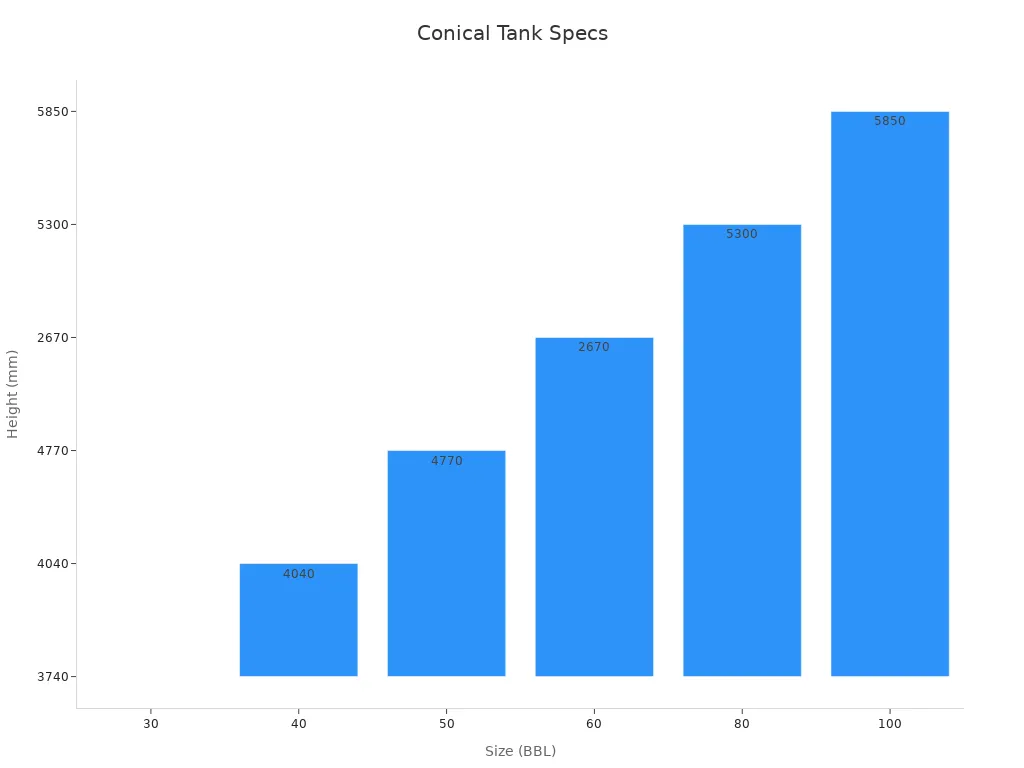

To give you an idea of their versatility, here’s a quick look at some common specifications:

| Size (BBL) | Dimensions (mm) | Height (mm) | Thickness (mm) |

|---|---|---|---|

| 30 | 1650 x 1850 | 3740 | 3 |

| 50 | 1750 x 2750 | 4770 | 3 |

| 100 | 2200 x 3350 | 5850 | 3 |

These cylindrical fermenters are built with high-quality stainless steel, ensuring durability and resistance to corrosion. Their energy-efficient designs also align with sustainable winemaking practices.

Benefits of Conical Tanks

Conical fermenters offer several advantages that make them stand out. First, their cone-shaped bottom simplifies yeast management. You can easily collect and reuse yeast, which helps maintain consistent flavor profiles across batches. This feature is especially valuable for wineries that prioritize efficiency.

Another benefit is improved clarity. The compact yeast bed at the bottom reduces suspended particles, resulting in a brighter, cleaner wine. Temperature control is another highlight. With cooling jackets or integrated systems, you can precisely manage fermentation temperatures, ensuring optimal results.

Here’s a quick comparison of their benefits:

| Benefit | Description |

|---|---|

| Efficient Yeast Management | Easy separation and reuse of yeast for consistent flavors. |

| Improved Clarity | Produces clearer wine with fewer particles. |

| Temperature Control | Precise management of fermentation conditions. |

| Closed System | Reduces contamination and oxidation risks. |

These tanks also support environmental sustainability. Their energy-saving designs and recyclable materials make them an eco-friendly choice for modern wineries.

Best Use Cases for Conical Tanks

Conical stainless steel fermentation tanks excel in both small-scale and large-scale winemaking. If you’re crafting premium wines or experimenting with new styles, these tanks provide the control and precision you need. They’re also ideal for wineries focused on sustainability, thanks to their energy-efficient features.

For commercial wineries, conical fermenters handle large volumes with ease while maintaining consistent quality. Their closed system design makes them perfect for producing delicate wines like whites and rosés, where oxygen exposure must be minimized.

Pro Tip: If you’re looking for a tank that combines efficiency, precision, and sustainability, conical fermenters are a fantastic investment.

Specialized Stainless Steel Wine Tanks for Sparkling Wine

Features of Sparkling Wine Tanks

Sparkling wine tanks are designed with precision to handle the unique demands of carbonation. These tanks are built to withstand high internal pressure, ensuring safety and durability during the secondary fermentation process. The walls are thicker than standard tanks, and they often include reinforced seals to prevent leaks.

Many sparkling wine tanks come equipped with specialized fittings, such as pressure relief valves and carbonation stones. These features help you control the level of dissolved CO₂, which is essential for achieving the perfect fizz. Some models also include integrated cooling systems to maintain the ideal temperature for fermentation.

Fun Fact: Sparkling wine tanks are sometimes called “autoclaves” because they can handle the same kind of pressure as industrial sterilization equipment!

Benefits of Sparkling Wine Tanks

These tanks offer several advantages that make them a must-have for sparkling wine production. First, their pressure-resistant design ensures safety while maintaining the wine’s carbonation. You can trust these tanks to deliver consistent results, batch after batch.

Another benefit is their ability to preserve the wine’s delicate flavors and aromas. The sealed environment minimizes oxygen exposure, which helps maintain the wine’s freshness. Plus, the integrated cooling systems allow you to control fermentation temperatures with ease.

Here’s a quick look at why winemakers love these tanks:

- Safety First: Built to handle high pressure without compromising quality.

- Flavor Preservation: Keeps your sparkling wine crisp and aromatic.

- Efficiency: Streamlines the carbonation process for faster production.

Best Use Cases for Sparkling Wine Tanks

If you’re producing sparkling wines like Champagne, Prosecco, or Cava, these tanks are essential. They’re perfect for wineries focused on large-scale production, as they ensure consistency across every bottle.

Smaller wineries can also benefit from these tanks, especially if you’re experimenting with sparkling wine styles. Their precise controls make it easier to fine-tune carbonation levels and flavor profiles.

Pro Tip: Investing in a high-quality sparkling wine tank can elevate your production process and help you stand out in the competitive sparkling wine market.

Insulated Stainless Steel Wine Tanks

Features of Insulated Tanks

Insulated stainless steel wine tanks are designed to maintain precise temperatures during fermentation and storage. Their insulation minimizes heat transfer, keeping your wine at the ideal temperature regardless of external conditions. This feature is especially useful for wineries in regions with fluctuating climates.

Many tanks come equipped with advanced heating and cooling systems. These systems allow you to control fermentation temperatures with pinpoint accuracy. Stainless steel’s excellent thermal conductivity enhances this process, ensuring consistent results.

Here’s a quick look at their thermal performance:

| Feature | Description |

|---|---|

| Temperature Control Ability | Stainless steel’s good thermal conductivity allows for effective temperature control during fermentation. |

| Equipped Systems | Many modern tanks come with heating and cooling devices to maintain ideal fermentation temperatures. |

The insulation levels vary, with some tanks offering higher efficiency through certified models. This ensures your wine remains stable and protected throughout the production process.

Benefits of Insulated Tanks

Insulated tanks offer several benefits that make them a smart choice for winemakers. First, they improve energy efficiency. Tanks with higher insulation levels, such as R-30, reduce standby losses by up to 8.5% compared to identical tanks with lower insulation. This means you save on energy costs while maintaining consistent wine quality.

Another advantage is their reliability. Insulated tanks prevent temperature fluctuations, which can negatively impact fermentation. They also reduce the risk of heat loss, ensuring your wine develops its flavors and aromas as intended.

- Rheem noted diminishing returns from increasing insulation thickness due to heat transfer rates.

- A.O. Smith highlighted reliability issues with polyurethane foam insulation exceeding 3 inches, leading to increased heat loss.

These tanks also align with sustainable practices. Their energy-saving features contribute to eco-friendly winemaking, making them a great choice for environmentally conscious wineries.

Best Use Cases for Insulated Tanks

Insulated stainless steel wine tanks excel in wineries that prioritize temperature control. If you’re producing wines that require precise fermentation conditions, such as whites or sparkling wines, these tanks are ideal. They’re also perfect for wineries in extreme climates, where maintaining stable temperatures can be challenging.

For large-scale production, insulated tanks ensure consistency across batches. Smaller wineries benefit too, especially if you’re experimenting with temperature-sensitive wine styles.

Tip: If you want to save energy and produce high-quality wine, insulated tanks are worth the investment.

Key Features to Look for in Stainless Steel Wine Tanks

Cooling and Heating Systems

Temperature control is one of the most critical aspects of winemaking, and stainless steel wine tanks excel in this area. Many tanks come with built-in cooling jackets or advanced heating systems that let you maintain precise fermentation temperatures. This ensures your wine develops its flavors and aromas just as you intend.

Here’s a quick breakdown of how these systems benefit your winemaking process:

| Feature | Benefit |

|---|---|

| Built-in cooling jackets | Regulate temperature effectively, preventing overheating. |

| Insulation | Reduces energy use and keeps fermentation temperatures stable. |

| Precision temperature control | Allows specific settings for consistent, high-quality wine production. |

These features are especially useful if you’re producing temperature-sensitive wines like whites or sparkling varieties. With precise control, you can avoid fermentation issues and ensure every batch meets your standards.

Tip: Look for tanks with integrated cooling jackets if you want to save energy and improve fermentation consistency.

Sample Valves and Thermometers

Sampling your wine during fermentation is essential for monitoring its progress. Stainless steel tanks often include sample valves, making it easy to draw small amounts of wine without disturbing the entire batch. This feature helps you check for clarity, taste, and aroma at different stages.

Thermometers are another must-have. They allow you to monitor the tank’s internal temperature in real time. This is crucial for maintaining the ideal conditions for fermentation. Some tanks even offer digital thermometers with remote monitoring capabilities, giving you added convenience.

Pro Tip: Choose tanks with easy-to-use sample valves and accurate thermometers to streamline your winemaking process.

Corrosion Resistance and Material Quality

The quality of the stainless steel used in your tank directly impacts its durability and performance. Most tanks are made from 304 or 316L stainless steel, which are government-certified for food-grade use. These materials undergo rigorous testing to meet ASTM A240 standards, ensuring they’re safe and reliable.

Here’s what makes these tanks stand out:

- Tanks are tested through a 12-stage verification process audited by third-party regulators.

- They comply with NSF, FDA, and local sanitation codes.

- Optional passivation treatments enhance corrosion resistance, especially for high-acidity wines.

Passivation involves a chemical process that removes free iron and forms a protective chromium oxide layer. This not only prevents corrosion but also ensures your wine remains free from metallic flavors.

Note: Investing in high-quality stainless steel tanks with passivation can extend their lifespan and protect your wine’s integrity.

Benefits of Stainless Steel Wine Tanks in Winemaking

Durability and Longevity

When it comes to durability, stainless steel tanks are unmatched. These tanks resist corrosion, even in harsh environments, ensuring they last for decades. With proper care, they can serve you for 20 to 30 years or more, significantly outlasting other materials like oak barrels. This longevity means fewer replacements, saving you money in the long run.

Here’s a quick comparison of their durability:

| Evidence Type | Details |

|---|---|

| Corrosion Resistance | Withstands harsh conditions, ensuring a longer service life. |

| Longevity | Lasts 20-30 years or more with proper care. |

| Low Maintenance Requirements | Reduces the need for frequent repairs or replacements. |

| Proven Track Record | Trusted in industries like food processing for decades. |

Stainless steel tanks are a reliable investment. Their robust construction ensures they can handle the demands of fermentation and aging without compromising quality.

Easy Maintenance and Cleaning

Cleaning stainless steel tanks is a breeze. Their non-porous surface prevents residue from sticking, making it easy to rinse away any buildup. A simple wash with hot water and a sanitizing solution is often all you need. For larger tanks, Clean-in-Place (CIP) systems streamline the process, saving you time and effort.

Here’s how stainless steel compares to other materials:

| Material Type | Lifespan | Corrosion Resistance | Maintenance Needs |

|---|---|---|---|

| Stainless Steel | 30-50 years | High | Minimal |

| Oak Barrels | 3-5 years | Low | High |

Unlike oak barrels, which require frequent cleaning and maintenance, stainless steel tanks simplify your workflow. Their smooth surface resists microbial buildup, ensuring a hygienic environment for your wine.

Tip: If you want to save time and reduce maintenance costs, stainless steel tanks are the way to go.

Preservation of Wine Quality

Stainless steel tanks excel at preserving the natural characteristics of your wine. Their airtight seals minimize oxygen exposure, keeping your wine fresh and vibrant. This is especially important for maintaining the fruit flavors and acidity in delicate wines.

Here’s why they’re a top choice for quality preservation:

- Airtight seals protect against oxidation, preserving freshness.

- Smooth surfaces reduce contamination risks, ensuring purity.

- Stainless steel doesn’t absorb flavors or aromas, letting your wine’s true character shine.

| Benefit | Description |

|---|---|

| Airtight Seals | Minimize oxygen exposure, preserving freshness and purity. |

| Preservation of Freshness | Maintains vibrant fruit flavors and natural acidity. |

| No Absorption | Ensures the true characteristics of the vineyard are showcased. |

| Reduced Contamination | Smooth, non-porous surfaces simplify cleaning and prevent spoilage. |

By using stainless steel tanks, you can trust that your wine will retain its intended flavor profile from fermentation to bottling.

Pro Tip: For wines that rely on delicate flavors and aromas, stainless steel tanks are an essential tool in your winemaking arsenal.

Comparing Stainless Steel Wine Tank Options

Cost and Value Analysis

When you’re choosing wine tanks, cost and value play a big role. Stainless steel tanks stand out because they’re cost-effective and built to last. Their simple design makes temperature control easy, which saves you money on energy bills. Cleaning is quick and hassle-free, reducing labor costs. Over time, these tanks prove to be a smart investment.

Another reason they’re worth the price is their resale value. If you ever decide to upgrade, stainless steel tanks are easy to sell. Plus, features like the ONGUARD Seismic System add minimal costs—usually just 0-4% of the tank’s price. This small addition can lower your insurance premiums, making the investment even more economical.

Performance and Efficiency

Performance matters when you’re crafting wine, and stainless steel tanks deliver. They’re designed to maintain precise fermentation conditions, ensuring consistent results. Features like cooling jackets and integrated temperature controls help you fine-tune the process. Whether you’re fermenting reds, whites, or sparkling wines, these tanks keep everything running smoothly.

Efficiency is another big win. Stainless steel’s non-porous surface prevents residue buildup, making cleaning fast and easy. You’ll spend less time scrubbing and more time focusing on production. Their durability also means fewer interruptions for repairs or replacements, keeping your winery productive year-round.

Suitability for Different Winemaking Styles

Stainless steel tanks adapt to a variety of winemaking styles. If you’re producing delicate wines like whites or rosés, their airtight seals protect against oxidation, preserving the wine’s freshness. For sparkling wines, pressure-resistant models handle carbonation with ease.

These tanks also work well for experimental batches. Their precise controls let you test new techniques without worrying about contamination or temperature fluctuations. Whether you’re running a boutique winery or a large-scale operation, stainless steel tank options offer the versatility you need to craft exceptional wine.

How to Choose the Right Stainless Steel Wine Tank

Assessing Production Needs

Start by thinking about your winery’s production goals. Are you crafting small batches of artisanal wine, or do you need to handle large-scale commercial production? The size and type of tank you choose should match your output. For example, variable capacity tanks work well for smaller wineries experimenting with different styles. On the other hand, closed-top or conical tanks are better suited for high-volume operations.

Consider the type of wine you’re making too. If you’re producing sparkling wine, you’ll need a tank that can handle high pressure. For temperature-sensitive wines like whites, insulated tanks with cooling systems are a smart choice.

Tip: Take stock of your current production levels and think about where you want to be in five years. This will help you pick a tank that fits your needs now and in the future.

Budget Considerations

Balancing quality and affordability is key when choosing a stainless steel wine tank. While it’s tempting to go for the cheapest option, remember that long-term maintenance costs can add up. These costs often represent 15-40% of total production expenses. Investing in a high-quality tank upfront can save you money over time by reducing repairs and replacements.

Here are a few things to keep in mind:

- Look for tanks that offer essential features like cooling jackets or sample valves.

- Avoid oversized tanks that don’t match your production needs.

- Consult industry professionals for advice. Their expertise can help you avoid costly mistakes and find the best value for your budget.

Pro Tip: Think of your tank as a long-term investment. Spending a little more now can lead to significant savings down the road.

Long-Term Scalability

Your winery might be small today, but what about tomorrow? Choosing a tank that supports growth is crucial. Modular tanks or those with variable capacity are excellent options. They adapt to changing production volumes, making them ideal for wineries planning to expand.

Also, consider tanks with advanced features like web-enabled diagnostics or integrated cooling systems. These technologies not only improve efficiency but also make scaling up easier.

Note: A tank that grows with your business ensures you won’t need to replace it as your production increases. This saves you time, money, and effort in the long run.

Choosing the right stainless steel wine tank can transform your winemaking process. Variable capacity tanks offer unmatched flexibility, closed-top tanks ensure precision, and conical tanks simplify sediment management. Each option has unique strengths, so think about your production goals and wine styles.

Start by asking yourself: What’s your priority? If you need versatility, go for variable capacity tanks. For large-scale production, closed-top tanks are a solid choice. Conical tanks are perfect for premium wines. Investing in a high-quality tank ensures durability, efficiency, and exceptional wine quality.

Remember: The right tank isn’t just equipment—it’s a partner in crafting your best wine yet.

FAQ

What makes stainless steel wine tanks better than oak barrels?

Stainless steel tanks last longer and are easier to clean. They don’t absorb flavors, so your wine’s natural taste shines through. Plus, they’re more cost-effective over time and allow precise temperature control for consistent results.

Can I use stainless steel tanks for both fermentation and storage?

Absolutely! Stainless steel tanks are versatile. You can ferment and store wine in the same tank. Their airtight seals and temperature control features make them perfect for both processes.

How do I clean a stainless steel wine tank?

Cleaning is simple. Use hot water and a food-safe sanitizing solution. For larger tanks, Clean-in-Place (CIP) systems make the process even easier. The smooth surface prevents residue buildup, so cleaning takes less time.

Are stainless steel tanks eco-friendly?

Yes! Stainless steel is recyclable, making it an environmentally friendly choice. These tanks also improve energy efficiency with features like insulation and cooling systems, reducing your winery’s carbon footprint.

What size stainless steel tank should I choose?

It depends on your production needs. Small wineries might prefer variable capacity tanks for flexibility. Larger operations often go for closed-top or conical tanks to handle higher volumes. Think about your current output and future growth when deciding.

Tip: Always consult a professional to ensure you pick the right tank for your winery’s goals.