When you choose a wine fermentation tank, the dimensions matter more than you might think. The right wine fermentation tank dimensions help control temperature, manage fermentation speed, and improve wine quality. You should look at the size based on how much wine you plan to make. A larger tank can boost production, but a smaller one gives you more control over the fermentation process. Picking the best wine fermentation tank for your needs shapes the flavor and style of your wine.

Key Takeaways

- Choosing the right wine fermentation tank size helps control temperature, oxygen exposure, and fermentation speed, which improves wine quality and flavor.

- Small tanks offer precise batch control and better cooling, while large tanks boost production but need extra systems to manage temperature and oxygen.

- Tank shape and features like sloped bottoms and adjustable lids improve cleaning, sediment removal, and batch flexibility, making your work easier.

- Modular and scalable tanks let your winery grow without replacing all equipment, saving money and maintaining quality over time.

- New trends in 2025 favor larger, energy-efficient tanks with advanced temperature control and sustainable designs to support better wine and lower costs.

Why Wine Fermentation Tank Dimensions Matter

Effects on Fermentation Quality and Wine Style

When you select a wine fermentation tank, the dimensions play a big role in the final wine. The size and shape of the tank affect temperature control, oxygen exposure, and the way flavors develop. Smaller tanks let you manage each batch closely. You can keep the temperature steady and limit oxygen, which helps preserve the unique flavor of each lot. Larger tanks work well for big batches, but you may need extra systems to control temperature and prevent too much oxygen from getting in.

Here is a table that shows how tank size changes the fermentation process and wine style:

| Aspect | Small Fermentors | Large Fermentors |

|---|---|---|

| Batch Control | Precise, separate lots | Less precise, blends lots |

| Lees Aging | Longer possible | Less common |

| Heat Dissipation | Better passive cooling | Needs active cooling |

| Oxygen Exposure | Lower, smaller headspace | Higher, needs inert gas |

| Operational Effort | More manual work | Needs machines |

| Risk of Foaming | Lower | Higher |

| Economies of Scale | Less economical | More economical |

You can see that wine fermentation tank dimensions shape the flavor influence and style of your wine.

Workflow Efficiency and Production Flexibility

Tank dimensions also affect how you work in the winery. The height, width, and bottom style of a tank change how easy it is to clean, move, and use. Tanks with sloped or conical bottoms help you remove sediment quickly. Variable capacity tanks let you make both small and large batches. This flexibility helps you save space and energy. You can adjust the lid to match the amount of wine, which keeps out oxygen and protects the wine.

- Tank size affects storage, energy use, and cooling.

- Bottom style changes cleaning and sediment removal.

- Adjustable lids give you batch flexibility.

- Proper spacing between tanks keeps your work area safe and efficient.

You can choose tanks that fit your workflow and make your job easier.

Scalability for Future Winery Growth

As your winery grows, you need tanks that can grow with you. Modular and scalable tanks let you add more capacity without changing your whole system. Many modern tanks use automation and energy-saving features. You can start with a few tanks and add more as you make more wine. This approach saves money and helps you keep quality high.

- Modular tanks support gradual growth.

- Automation and energy efficiency lower costs.

- You can upgrade or expand without replacing everything.

- Scalable tanks help you meet new production goals.

Choosing the right wine fermentation tank dimensions now helps you prepare for future success.

Stainless Steel Wine Fermentation Tank Dimensions

Common Sizes and Capacity Ranges

You will find that stainless steel fermentation tanks come in many sizes to fit different winery needs. In 2025, the most popular tanks have a capacity range from 500 to 13,000 gallons. Many wineries choose in-stock sizes like 1,200 and 1,500 gallons because these work well for both small and large batches. The table below shows the most common tank sizes and their typical capacities:

| Tank Size Category | Capacity Range (gallons) | Notable In-Stock Sizes (gallons) |

|---|---|---|

| Combination Fermentation/Storage Tanks | 500 to 13,000 | 1,200, 1,500 |

These tanks often feature a truncated cone top, a flat or sloping floor, and cooling jackets for temperature control. You can also find multiple ports for venting, racking, and draining, which make your workflow easier.

Best Use Cases for Stainless Steel Tanks

You should choose stainless steel fermentation tanks when you want flexibility and precise temperature control. These tanks work well for both fermentation and storage. If you make red wine, you may use open top fermenters or conical fermenters to help with cap management and sediment removal. For white wine, closed fermentation tanks with circular manholes help keep oxygen out and protect delicate flavors. Stainless steel vs oak tanks offer more control over the process and do not add extra flavors, so you can highlight the true character of your grapes.

Tip: Always leave about 25% free space in your tank during fermentation. This space helps manage foaming in white wines and cap development in red wines.

SDCHENMA Stainless Steel Tank Features

When you select SDCHENMA stainless steel fermentation tanks, you get advanced features designed for modern wineries. Each tank comes with a cooling jacket for precise temperature control. You can choose from a wide range of capacities to match your production goals. SDCHENMA tanks include multiple tri-clover ports, a thermometer package, and a detachable steel base with adjustable footpads. You can also request custom designs to fit your space and workflow. These tanks support both small-batch and large-scale production, making them a smart choice for any winery looking to grow.

Concrete Wine Fermentation Tank Dimensions

Typical Shapes and Size Options

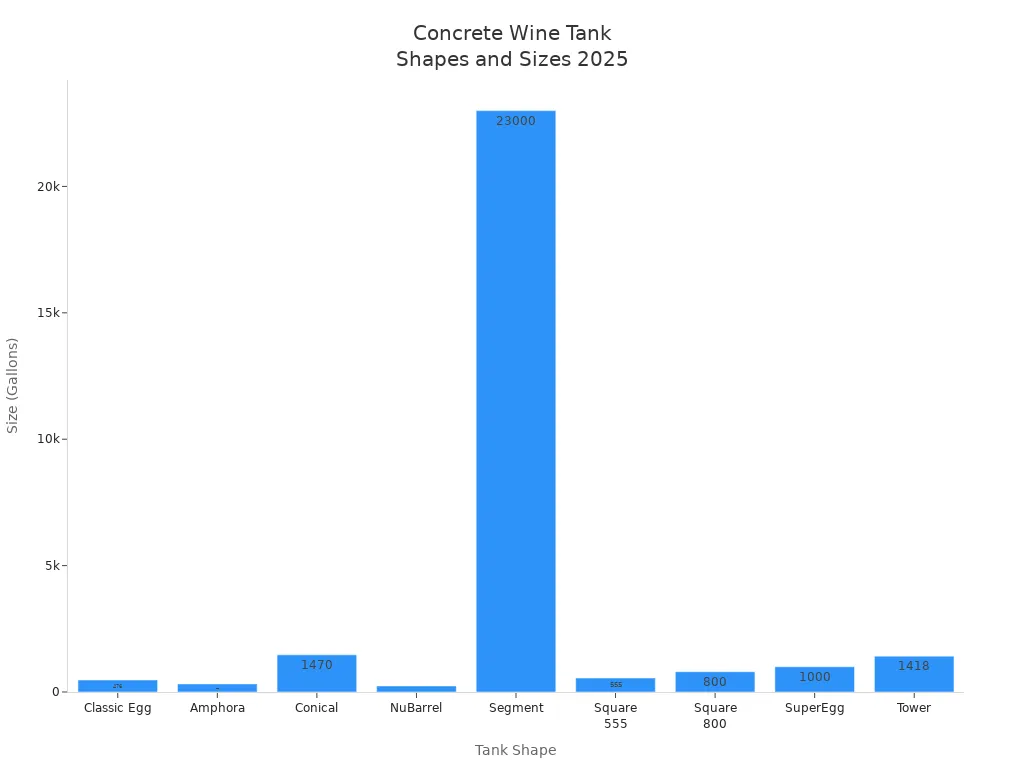

You can choose from many shapes when you look at concrete wine fermentation tanks in 2025. Each shape offers unique benefits for your winemaking process. The classic egg shape helps with natural mixing during fermentation. Amphora tanks give you a traditional look and modern temperature control. Conical tanks provide strength and easy cleaning. Some tanks, like the NuBarrel and Segment, offer compact or large options for different winery needs. You can also find square, SuperEgg, and tower shapes, each with special features.

Here is a table showing the most common shapes and their size options:

| Tank Shape | Size Options (Gallons) | Key Features |

|---|---|---|

| Classic Egg | 476 | Seamless, cornerless design; ideal for fermentation |

| Amphora | 320 | Embedded glycol for temperature control |

| Conical | Up to 1,470 | Durable layered concrete; 10-year guarantee |

| NuBarrel | 240 | Compact size; customizable colors and logos |

| Segment | Up to 23,000 | Large capacity; embedded glycol system |

| Square | 555, 800 | Durable construction; customizable options |

| SuperEgg | 1,000 | Egg shape benefits; showroom quality finish |

| Tower | 1,418 | Embedded glycol; customizable branding |

Note: All these tanks come with a 10-year guarantee against cracks and leaks. You can also customize colors and logos to match your winery’s brand.

Capacity Ranges for Concrete Tanks

You will find that concrete wine fermentation tanks come in many sizes. Commercial wineries often use amphorae with 800 liters. Traditional Georgian kvevri tanks can be as small as 20 liters or as large as 10,000 liters. Some wineries use smaller 300-liter tanks for experiments. Most commercial concrete tanks range from a few hundred liters up to several thousand liters. In some cases, you can find tanks with a capacity close to 10,000 liters.

- 300-liter tanks work well for small batches or trials.

- 800-liter amphorae are common in many wineries.

- Traditional tanks can reach up to 10,000 liters for large-scale production.

SDCHENMA Concrete Tank Solutions

SDCHENMA offers a wide selection of concrete wine fermentation tanks to fit your needs. You can select from classic egg, amphora, conical, and other modern shapes. Each tank features an embedded glycol cooling system for precise temperature control. You can choose tanks with different capacities to match your production goals. SDCHENMA tanks come with a 10-year guarantee against cracks and leaks. You can also customize the color and logo to reflect your winery’s style. These tanks help you create high-quality wine while supporting your brand and workflow.

Oak Wine Fermentation Tank Dimensions

Standard Oak Tank Sizes

You will find that oak barrels come in many standard sizes. The most common size is the barrique, which holds about 225 liters (59 gallons). You might also see puncheons, which hold around 500 liters (132 gallons). Some wineries use larger oak barrels called foudres, which can hold up to 1,000 liters (264 gallons) or more. Each size gives you different results in your wine. Smaller oak barrels give more oak flavor to the wine. Larger barrels let the wine age slowly and keep the flavors softer.

| Oak Barrel Type | Capacity (Liters) | Capacity (Gallons) |

|---|---|---|

| Barrique | 225 | 59 |

| Puncheon | 500 | 132 |

| Foudre | 1,000+ | 264+ |

Volume Options and Applications

You can choose oak barrels for many types of wine. Small oak barrels work well for red wines that need strong oak flavors. Large oak barrels help you make white wines with gentle oak notes. Some winemakers use a mix of sizes to create unique blends. Oak barrels also help with micro-oxygenation, which means the wine gets a small amount of air. This process helps the wine develop smooth textures and rich aromas. When you compare stainless steel vs oak, you see that oak barrels add flavor and texture, while stainless steel keeps the wine pure and fresh.

Tip: Use smaller oak barrels if you want more oak flavor in less time. Use larger barrels for a softer, slower aging process.

SDCHENMA Oak Tank Offerings

SDCHENMA offers a wide range of oak barrels for your winery. You can select from classic barriques, puncheons, or large foudres. Each oak barrel uses high-quality wood and expert craftsmanship. You can choose the size that fits your production needs. SDCHENMA can also help you customize your oak barrels with special toasting levels or unique shapes. These oak barrels work well for both red and white wines. You can trust SDCHENMA to provide oak barrels that help you create the wine style you want.

Plastic Wine Fermentation Tank Dimensions

Popular Sizes for Small-Scale Production

Plastic wine fermentation tanks come in many sizes. You can find small tanks for home batches and larger ones for small wineries. Most small-scale producers use tanks that hold between 15 and 500 liters. These sizes work well for making wine in small batches. The table below shows the most common size ranges:

| Size Range (Liters) | Size Range (Gallons) | Usage Context |

|---|---|---|

| 15 – 109 | 4 – 29 | Common for small-scale wine fermentation, under 60 gallons category |

| 110 – 500 | 29 – 132 | Also used in small-scale production, larger batch sizes within hobbyist or small winery scale |

You often see food-grade plastic containers in these sizes. Many hobbyists and small wineries choose them because they are a cost-effective option. These tanks make it easy to start winemaking without a big investment.

Flexibility and Portability

Plastic tanks give you great flexibility. You can move them easily, even when full. Their lightweight design makes them much easier to handle than stainless steel or concrete tanks. You can stack them to save space in your winery or storage area. Here are some reasons why plastic tanks stand out:

- Plastic tanks weigh much less than stainless steel or concrete tanks.

- You can transport them with less effort and lower costs.

- Stackable designs help you use your space better.

- Plastic tanks work well for small-scale or experimental winemaking.

You can use plastic tanks for many different projects. Their portability helps you adjust your setup as your needs change.

SDCHENMA Plastic Tank Choices

SDCHENMA offers a range of plastic wine fermentation tanks for small-scale producers. You can choose from several sizes to match your batch size. Each tank uses food-grade materials to keep your wine safe. The lightweight build makes them easy to move and clean. SDCHENMA plastic tanks help you start or expand your winemaking with less effort. You can rely on these tanks for flexibility and convenience in your winery.

Amphora and Clay Wine Fermentation Tank Dimensions

Traditional and Modern Size Variations

You can find amphora and clay wine fermentation tanks in many shapes and sizes. A traditional amphora, made by skilled potters, stands about 30 inches tall and measures 6 to 8 inches wide. The vessel has a narrow base and a broad shoulder, with the shoulder formed about two-thirds up the height. The neck above the shoulder is narrower, with an opening about 5 inches wide. Handles connect the neck to the shoulder, making it easier to lift the vessel. When filled, a traditional amphora can weigh about 10 pounds per gallon.

Modern amphorae come in larger sizes for winery-scale fermentation. Producers now use advanced firing techniques, reaching temperatures up to 1200°C. This process reduces porosity and removes the need for resin or epoxy sealing. You will see regional styles like Qvevri from Georgia, Talha from Portugal, and Tinaja from Spain. Amphorae now appear in wineries around the world, including places known for oak barrels. Many winemakers use amphorae for long aging periods and may transfer wine between vessels before bottling.

Best Use Scenarios for Amphora Tanks

You will find amphora tanks work best for small-scale or artisanal wine production. Winemakers often use them for initial fermentation in the eastern Mediterranean and Greece. Amphorae serve as portable vessels for secondary fermentation and aging after the first stage in larger vats. Their size and shape make them ideal for small installations or when you need to move must quickly into portable containers. Amphora tanks also act as intermediate vessels between larger dolia and other stages of production. These tanks fit well with traditional, small-batch, or experimental winemaking. If you want to try open fermentation tanks for unique wine styles, amphorae offer a flexible and historic option.

Tip: Amphora tanks help you create wines with distinct character and a connection to ancient winemaking traditions.

SDCHENMA Amphora Tank Products

SDCHENMA provides a range of amphora and clay wine fermentation tanks to support your winemaking goals. You can select from traditional shapes or modern designs, each crafted for durability and performance. SDCHENMA uses high-quality clay and advanced firing methods to ensure strength and low porosity. You can choose tanks in various sizes to match your batch needs, from small artisanal lots to larger winery projects. Each amphora tank supports both fermentation and aging, giving you flexibility in your production process. SDCHENMA helps you bring the art of ancient winemaking into your modern winery.

Hybrid and Customizable Wine Fermentation Tank Dimensions

Custom Dimension Options and Modular Designs

Hybrid wine fermentation tanks in 2025 give you more control over your winemaking process. These tanks combine materials like stainless steel and wood, letting you use both modern and traditional methods. You can pick from many custom dimension options and modular designs:

- Mix stainless steel with wood inserts for unique flavor and precision.

- Use modular systems with interchangeable tops and bottoms for easy upgrades.

- Order tanks in custom sizes and shapes to fit your winery’s layout.

- Add special ports or combine materials like glass for specific needs.

- Choose tanks with your own branding for a unique look.

- Try quick-change wood staves and 3D design mockups for planning.

- Scale your system from small research batches to full production.

These features help you adapt as your winery grows or changes.

When to Choose the Right Wine Fermentation Container

You need to think about several factors when you choose the right wine fermentation container. Start by matching tank size to your production goals. Make sure the tank fits your space and workflow. Tanks with built-in temperature control and insulation help you keep the right conditions for fermentation. Custom tanks let you pick the shape, size, and features you need, like oxygen management or mixing systems. Some tanks have floating lids to adjust the volume and prevent oxidation. Stackable or square tanks save space in tight areas. Built-in mixing systems can make your job easier and improve wine quality.

Tip: Always consider your long-term plans and budget. High-quality tanks last longer and save money over time.

You should choose the right wine fermentation container based on your wine style, production needs, and available space.

SDCHENMA Custom Tank Solutions

SDCHENMA offers custom hybrid and modular wine fermentation tanks to fit your unique needs. You can work with their engineers to design tanks with special dimensions, shapes, and features. SDCHENMA supports you with 3D mockups, quick-change wood staves, and modular accessories. You can scale your system as your winery grows. Their custom tanks help you choose the right wine fermentation container for any stage of your business, from small batches to large-scale production.

Comparing Wine Fermentation Tank Dimensions Across Types

Size and Capacity Comparison by Tank Type

You can find many types of wine fermentation tanks, each with its own size and capacity range. The right tank helps you control your wine’s quality and production. Here is a table that compares common tank types by their capacity and main features:

| Tank Type | Capacity Range | Advantages | Disadvantages |

|---|---|---|---|

| Stainless Steel | 100 to 50,000+ liters | Flexible, easy to clean, precise temperature control | Higher upfront cost |

| Concrete | 600 to 3,200 liters | Stable temperature, unique micro-oxygenation | Heavy, less portable |

| Oak Barrels | 225 to 860 liters | Adds flavor, best for premium wines | Limited size, needs more care |

| Plastic | 20 to 1,000 liters | Lightweight, affordable, easy to move | Limited to small batches |

| Amphora/Clay | 30 to 1,000+ liters | Traditional, unique wine style | Fragile, harder to clean |

| Bladder Tanks | 25 to 25,000 gallons | Portable, customizable sizes | Temporary use |

| Folding Tanks | 500 to 5,000 gallons | Quick setup, good for emergencies | Limited capacity |

| Fiberglass | 4,000 to 50,000 gallons | Durable, moderate cost | Can crack if not maintained |

You can see that stainless steel tanks cover the widest range of capacities. Oak barrels and amphorae work best for small, high-quality batches. Plastic tanks suit small wineries or experimental batches. Concrete tanks offer a balance between size and wine style.

Note: The size of your tank affects how much wine you can make at once and how you manage fermentation.

Suitability for Different Winery Sizes and Production Levels

Choosing the right tank depends on your winery’s size and how much wine you want to produce. Here is a guide to help you match tank capacity to your production level:

| Winery Scale | Recommended Tank Capacity | Typical Use Case |

|---|---|---|

| Small (Boutique) | ~60 gallons (~227 liters) | Small batch production, experiments |

| Medium (Mid-size) | 600 to 1,000 gallons (2,271–3,785 liters) | Core wines, estate lines, larger batches |

| Large (Industrial) | 5,000 to 100,000+ liters | Bulk wine, export, high-volume production |

- Small wineries often use plastic, oak, or small stainless steel tanks. These tanks help you control each batch and try new wine styles.

- Medium wineries use stainless steel, concrete, or larger oak tanks. These tanks let you make more wine while keeping quality high.

- Large wineries need big stainless steel or fiberglass tanks. These tanks handle large batches and help you meet export or bulk orders.

Plastic tanks (20–1,000 liters) work well for trials and small commercial batches. Stainless steel tanks fit all winery sizes because you can find them in many dimensions. Concrete tanks (600–3,200 liters) are best for boutique and mid-size wineries. Oak barrels (225–860 liters) are best for premium wines in smaller batches.

Tip: Match your tank size to your batch size. This helps you avoid wasted space and keeps your wine safe from too much air.

Flexibility and Expansion Potential

You want your winery to grow and change with your needs. Some types of wine fermentation tanks give you more flexibility than others. Variable capacity tanks let you adjust the volume for each batch. You can fill them to different levels, which helps you prevent oxidation and save space. Stainless steel tanks often come with features like cooling jackets and cleaning systems. These features make them easy to use for both small and large batches.

If you plan to expand, modular tanks or stackable plastic tanks help you add more capacity without changing your whole setup. You can start with a few tanks and add more as your production grows. Concrete and oak tanks are less flexible because of their weight and fixed size, but they add special qualities to your wine.

Here is a quick list of what to look for if you want flexibility:

- Variable capacity tanks for batch adjustments

- Modular or stackable designs for easy expansion

- Tanks with built-in temperature control for quality fermentation

- Easy-to-clean materials for faster turnaround

Choosing the right wine fermentation tank dimensions now helps you save money and time as your winery grows. Stainless steel tanks are best for flexibility and future expansion, but you can mix tank types to match your wine style and production goals.

Factors to Consider to Choose the Right Wine Fermentation Container

Matching Tank Size to Winery Production Volume

Choosing the right tank size is one of the most important factors to consider when choosing a wine fermentation tank. You want to match your tank size to your winery’s annual production volume. This helps you avoid wasted space and keeps your process efficient. If you use a tank that is too large for your batch, you risk exposing your wine to too much air. If your tank is too small, you may not have enough room for fermentation activity.

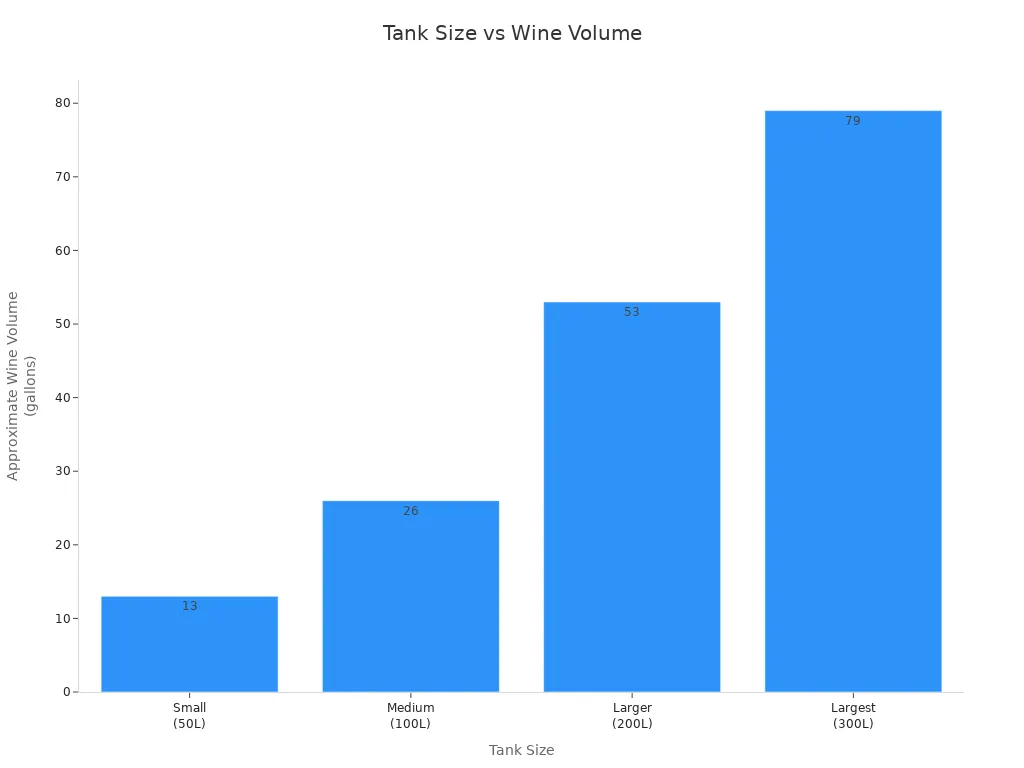

Here is a table to help you select the right tank size for your winery scale:

| Tank Size | Approximate Wine Volume | Suitable Winery Scale |

|---|---|---|

| Small (e.g., 50L) | ~13 gallons | Home use |

| Medium (e.g., 100L) | ~26 gallons | Small wineries |

| Larger (e.g., 200L) | ~53 gallons | Medium wineries |

| Largest (e.g., 300L) | ~79 gallons | Large wineries |

You can see how each tank size fits a different production level. This structured approach helps you plan for growth and manage your batches with confidence.

Tip: Always plan for a little extra capacity. This gives you flexibility during busy harvest seasons.

Wine Style and Fermentation Needs

The style of wine you want to make will guide your choice of tank. This is another key factor to consider when choosing a wine fermentation tank. Different wine styles need different tank features and dimensions. For example, white wines and rosés often need stainless steel tanks. These tanks help you control temperature and keep flavors crisp. Red wines benefit from tanks that allow gentle oxygen exposure, like oak or concrete. These materials help develop complex flavor and texture.

You also need to think about the space needed for fermentation activity. White wines foam during fermentation, so you should leave about 25% of the tank empty. Red wines have solids that rise and form a cap, which also needs extra space. For example, if you want to make 50 gallons of red wine, you need a tank that holds about 95 gallons. This extra space prevents spills and helps you manage the fermentation safely.

Note: Tank size and material both affect the final flavor of your wine. Stainless steel keeps flavors pure, while oak and concrete add unique notes.

Space, Infrastructure, and Budget Considerations

Space and infrastructure play a big role in your decision. You need to fit your tanks into your winery without crowding your workspace. Stackable or modular tanks help you use your space better. These tanks let you expand as your business grows. You can start with a few tanks and add more later, which helps you manage your budget and infrastructure.

Your budget is another important factor to consider when choosing a wine fermentation tank. The price of tanks varies by size, material, and features. Stainless steel tanks often have a higher price, but they last a long time and offer good value. Oak and concrete tanks have a different price range and bring unique benefits to your wine. Plastic tanks have a lower price and work well for small batches or experiments.

Here are some points to help you balance space, infrastructure, and cost:

- Measure your available space before you buy tanks.

- Choose modular or stackable tanks for easy expansion.

- Compare the price of different tank materials and sizes.

- Plan your investment to match your production goals and cash flow.

- Remember that the cost of a tank includes not just the purchase price, but also maintenance and long-term value.

Planning ahead helps you avoid costly mistakes and supports your winery’s growth.

Trends in Wine Fermentation Tank Dimensions for 2025

Demand for Larger or Smaller Tanks

You see a strong trend toward larger wine fermentation tanks in 2025. As global wine production grows, especially in South America and Australia, many wineries choose tanks with higher capacity. Larger tanks help you manage bigger batches and improve efficiency. Premium wine producers often select enclosed tanks because these tanks offer better hygiene and quality control. Smaller tanks still play a role, but mostly in craft brewing, not in the main wine industry. You notice that stainless steel tanks remain the top choice, while concrete tanks gain popularity for their unique impact on flavor.

- Large-capacity tanks support expanding wine regions.

- Enclosed tanks help you maintain clean fermentation and protect flavor.

- Stainless steel tanks dominate, but concrete tanks are gaining interest.

Innovations in Tank Design and Materials

You benefit from new technology in wine fermentation tanks. Automation and precision fermentation systems help you control temperature and improve consistency. Many tanks now include advanced temperature control features, such as cooling jackets and sensors. You can use IoT devices to monitor fermentation remotely. Some wineries use AI and machine learning to optimize the process and maintain the right temperature for each batch. Modular and customizable tanks let you adjust your setup as your winery grows. These innovations help you create wine with better flavor and reliable results.

Note: Modern tanks with temperature control give you more power to shape the flavor of your wine during fermentation.

Sustainability and Efficiency Trends

You see a growing focus on sustainability in wine fermentation equipment. Many wineries look for energy-efficient tanks that help reduce costs and environmental impact. Eco-friendly materials and designs are becoming more common. You can find tanks that use less water and energy during cleaning and fermentation. Modular tanks allow you to expand without wasting resources. Government incentives also encourage you to choose sustainable solutions. These trends help you make wine that meets both quality and environmental goals.

- Energy-efficient tanks lower your operating costs.

- Eco-friendly materials support sustainable wine production.

- Modular designs help you grow your winery with less waste.

You can choose the best wine fermentation tank dimensions by thinking about your wine style, production needs, and space. Look at how each tank type fits your winery’s goals. New trends in tank design help you make better wine and save energy. Plan for the future so your winery can grow. Remember, the right tank size helps you control quality and reach your goals in 2025.

FAQ

What is the best tank size for a small winery?

You should choose tanks between 100 and 1,000 liters. These sizes let you control each batch and experiment with different wine styles. Small tanks also fit well in limited spaces.

How much space should I leave in a tank during fermentation?

Leave about 25% of the tank empty. This space helps manage foaming and cap rise, which keeps your wine safe from spills and oxidation.

Can I mix different tank types in my winery?

Yes, you can use stainless steel, oak, and concrete tanks together. Mixing tank types lets you create unique wine styles and match each batch to the best container.

Do tank dimensions affect wine flavor?

Yes. Tank size and shape change temperature control and oxygen exposure. These factors influence how your wine develops flavor, aroma, and texture.

How do I clean and maintain my fermentation tanks?

Always rinse tanks with warm water after each use. Use a food-safe cleaner for deep cleaning. Inspect tanks for residue or damage before every batch. Regular cleaning keeps your wine safe and your tanks in good condition.